Virtual testing and inspection of a virtual weldment

A technology of virtual testing and welding, applied in the field of virtual testing and inspection of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

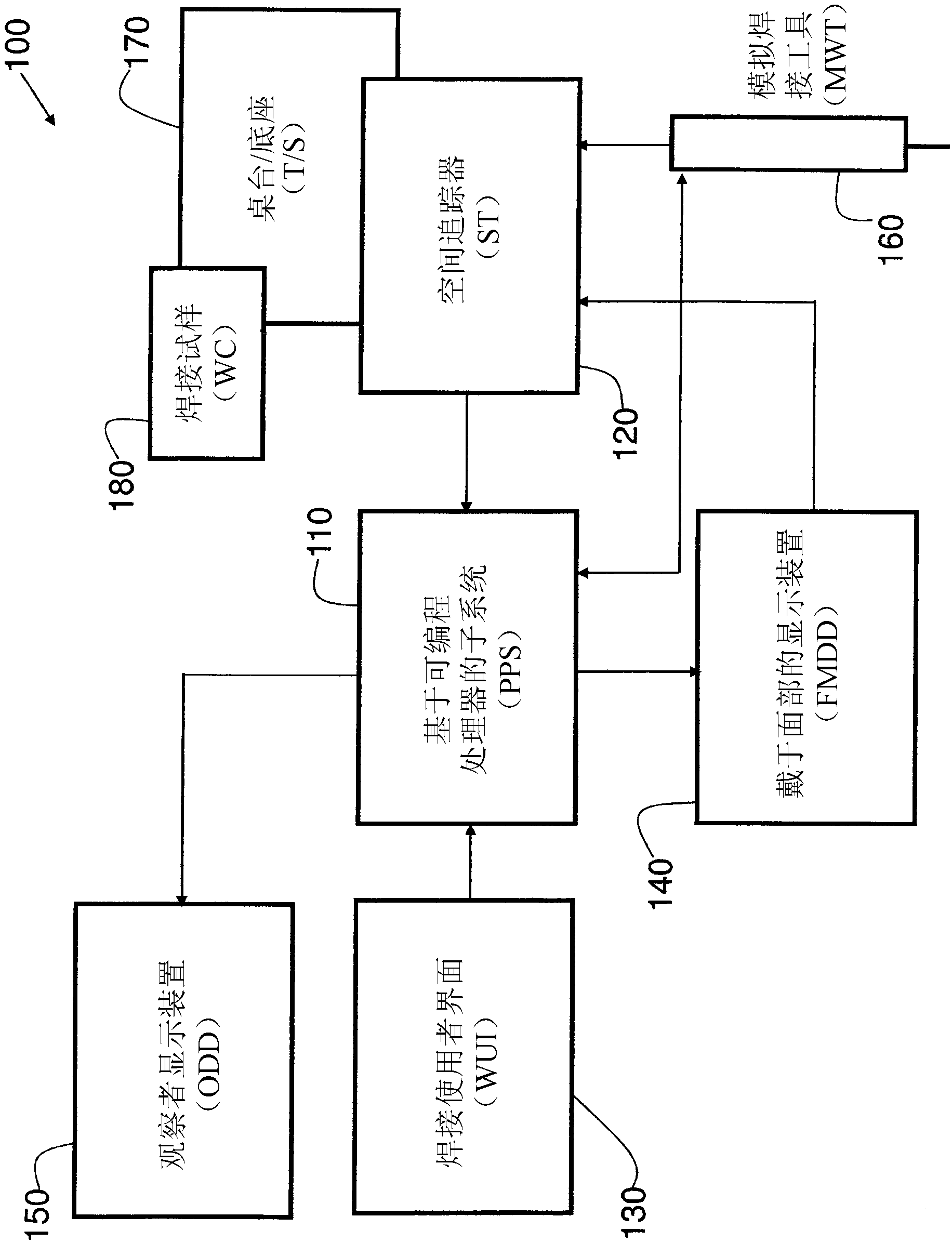

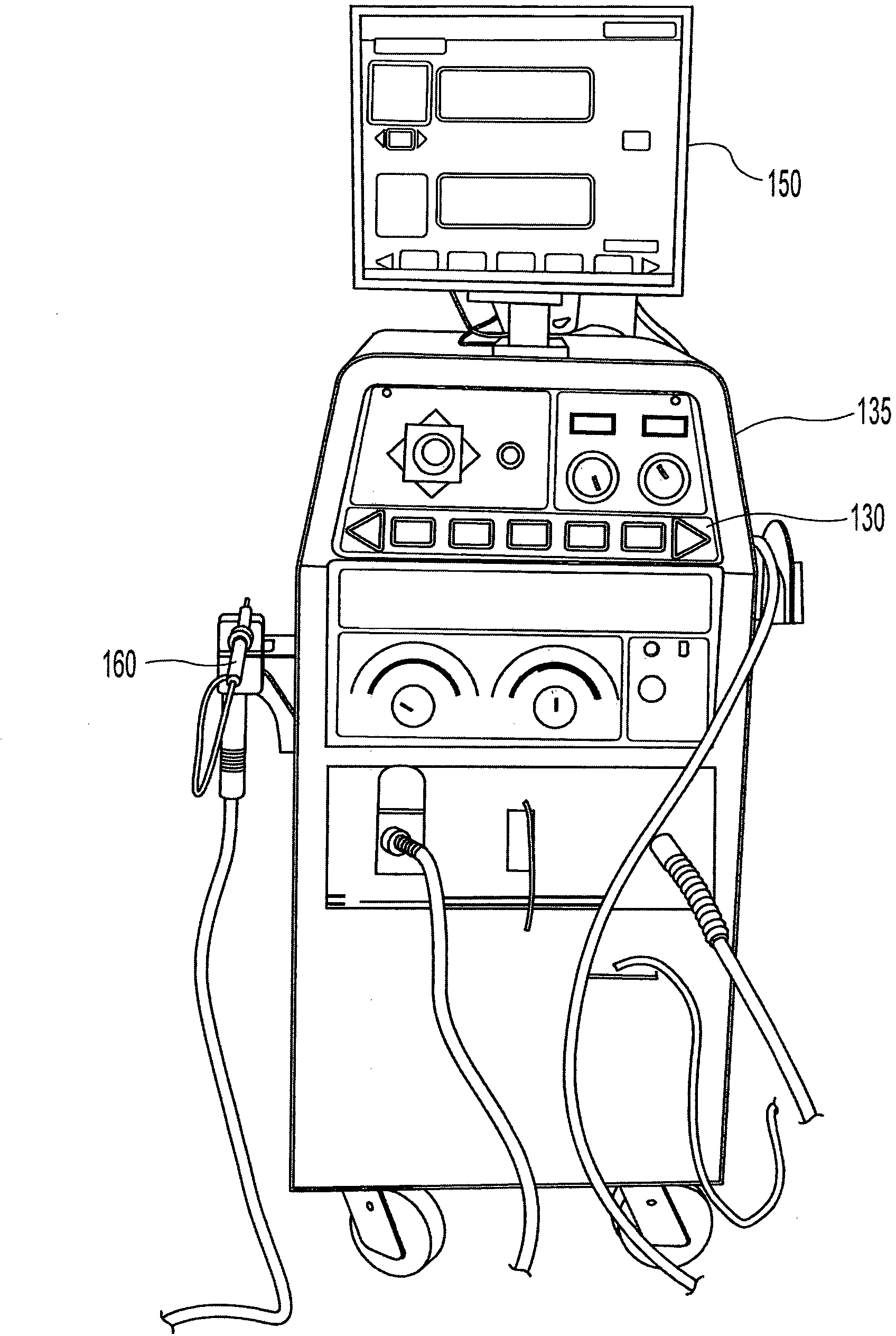

Method used

Image

Examples

Embodiment approach

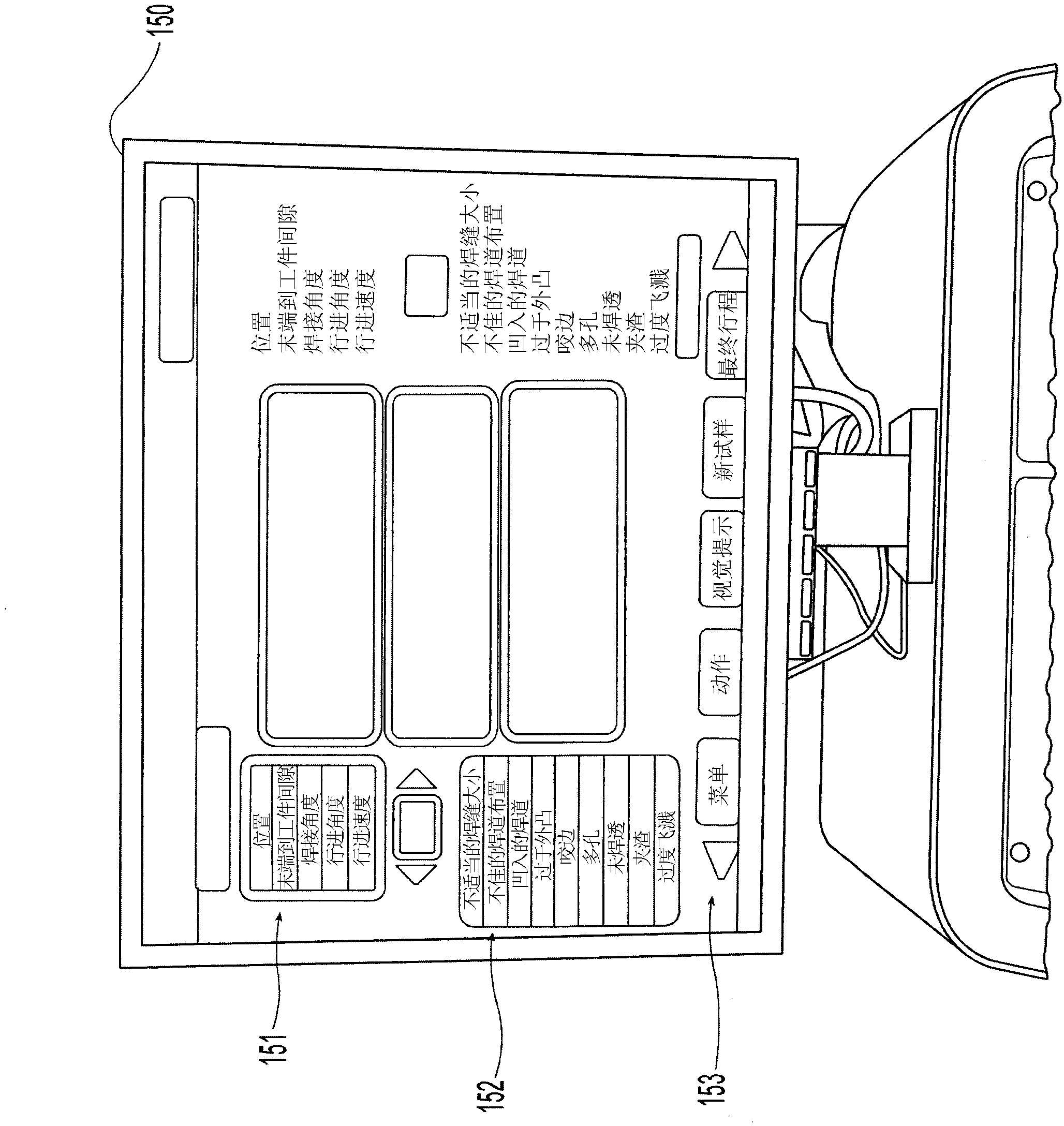

[0057] As previously discussed herein, intelligent agents can be employed to provide feedback to a student on areas where the student needs more practice, or to provide feedback to the instructor or instructor on how to modify the instructional curriculum to improve the student's learning. In artificial intelligence, an intelligent agent is an autonomous entity, usually implemented in software, that observes and acts on the environment and directs its actions toward a goal to be achieved. An intelligent agent is able to learn and use knowledge to achieve a goal (eg, the goal of providing relevant feedback to welding students or welding instructors). According to embodiments of the present invention, for example, the environment perceived and acted upon by the intelligent agent is a virtual reality environment generated by the VRAW system.

[0058] Also, various interactive inspection tools may be used on the virtual weldment before being tested or on the virtual weldment after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com