Low-pressure fast-drainage plaster mold and manufacturing method

A gypsum mold and low-pressure technology, which is applied in the production field of the aforementioned low-pressure fast-draining gypsum mold, can solve the problems of gas pressure transfer discount, limited gas pressure transmission, and gas pressure drop, and achieves stable improvement of production efficiency and operability. Stable and reliable, the effect of positioning without displacement and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

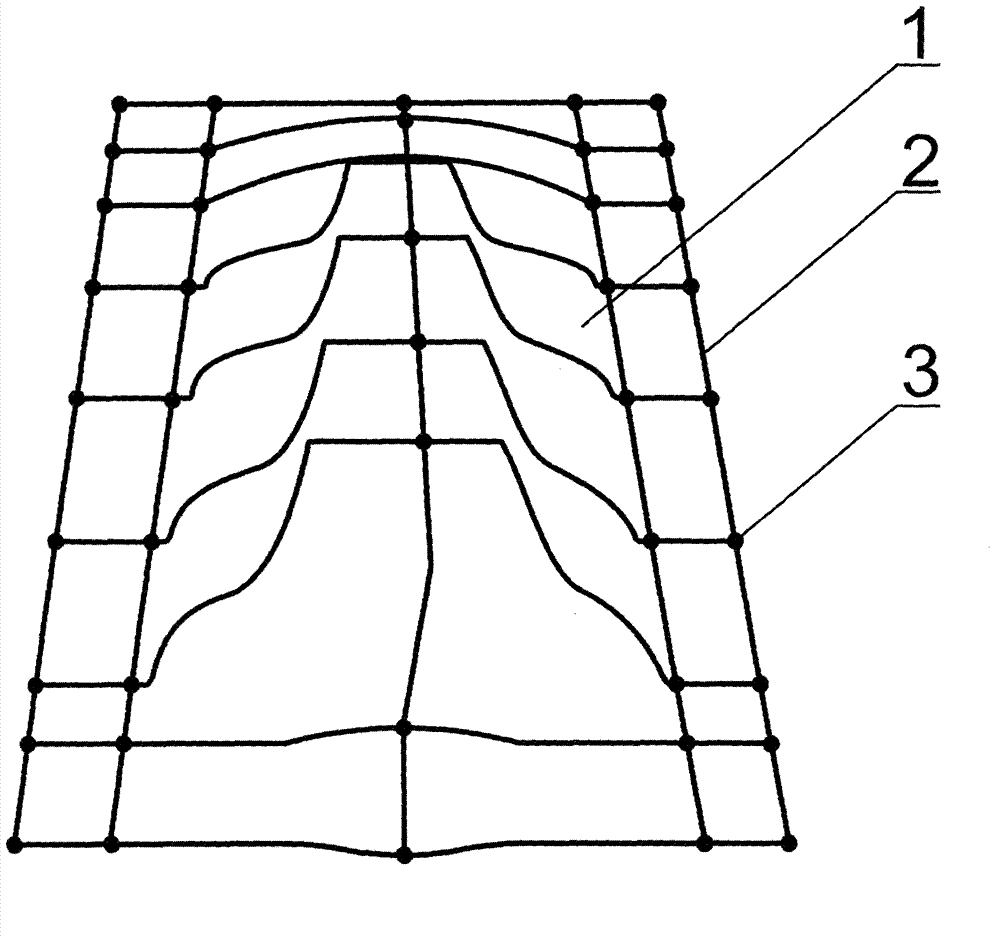

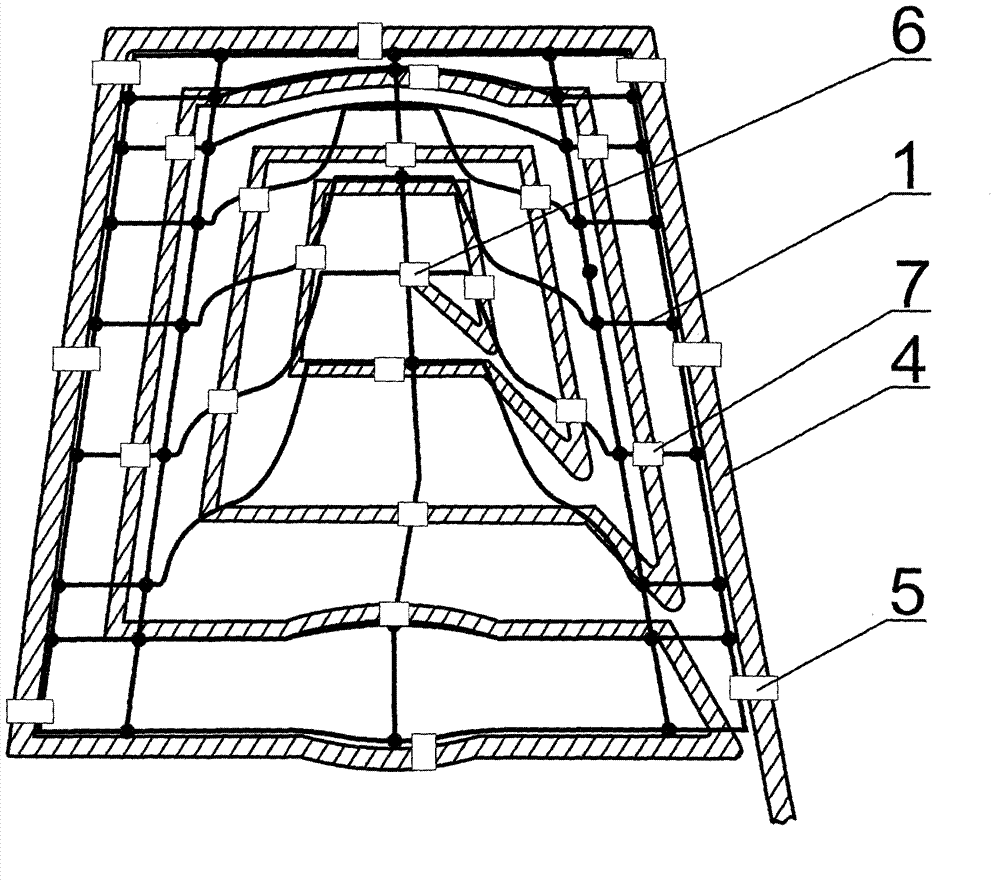

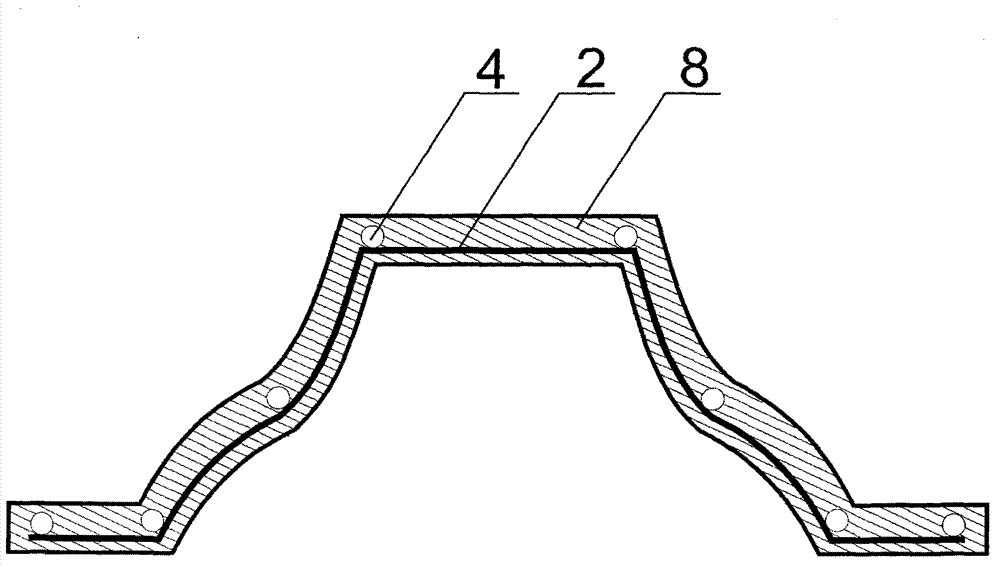

[0026] Such as figure 1 , figure 2 , image 3 As shown, a low-pressure quick-drainage gypsum mold includes a mold body (8) made of gypsum material, and a ¢8mm plastic hose (4) is buried in the middle of the mold body (8) thickness, and the plastic hose (4) Micropores are evenly distributed on the top, and a special-shaped support (1) is embedded in the middle of the thickness of the phantom (8). The hole size of the microholes on the plastic hose (4) is ¢1mm, and the transverse spacing between the microholes is 3mm, and the vertical spacing is 5mm.

[0027] Such as figure 1 As shown, in this embodiment, the special-shaped support (1) is composed of ¢6mm iron wire (2) braided, and has a mesh structure, and its shape is consistent with the mold body (8). Each intersection of the iron wire (2) passes through the first nylon Cable ties (3) are fixedly conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com