Train capable of moving equipment

A technology for mobile equipment and trains, which is applied to trucks, transport passenger cars, railway car body parts, etc., and can solve problems such as inconvenient disassembly, long construction period, and restrictions on production development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

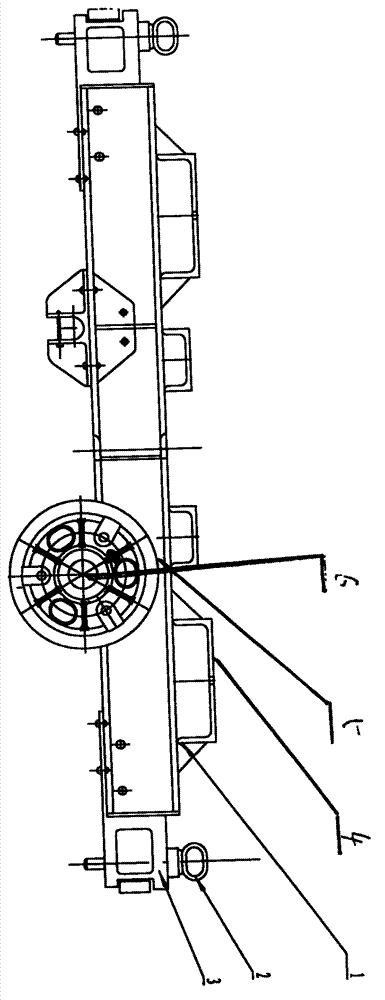

[0008] The present invention is described in further detail below in conjunction with accompanying drawing embodiment, and as shown in the accompanying drawing mobile equipment train, its structural setting is to arrange a flat car plate 1, and axle 6 is arranged on the front and rear ends of vehicle frame 3 bottoms, and axle 6 two ends Wheels 5 are arranged at the end, the vehicle board 1 is arranged on the vehicle frame 3, and the large electromechanical equipment 4 is firmly arranged on the vehicle board 1 by bolts.

[0009] In the movable equipment train of the present invention, the large-scale electromechanical equipment 4 is firmly arranged on the vehicle board through bolts, which solves the problem that the large-scale electromechanical equipment in the coal mine is stable, needs to be laid foundation, poured concrete, and fixed by bolts, and cannot be moved. Compared with the technology, it has the advantage of being able to move at any time according to the needs of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com