Conveying roll table used for corrugated steel plates and straight steel plates

A technology for conveying roller tables and corrugated steel plates, which is applied in the direction of roller tables, transportation and packaging, etc., which can solve the problems of large limitations of roller tables, single function of roller tables, and obstacles to the normal transmission of corrugated steel sheets, so as to reduce labor intensity and improve adaptability Sexuality, the effect of improving the efficiency of conveying work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

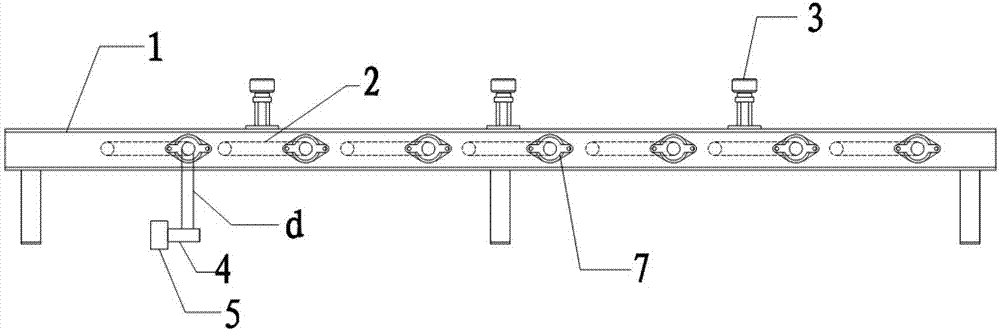

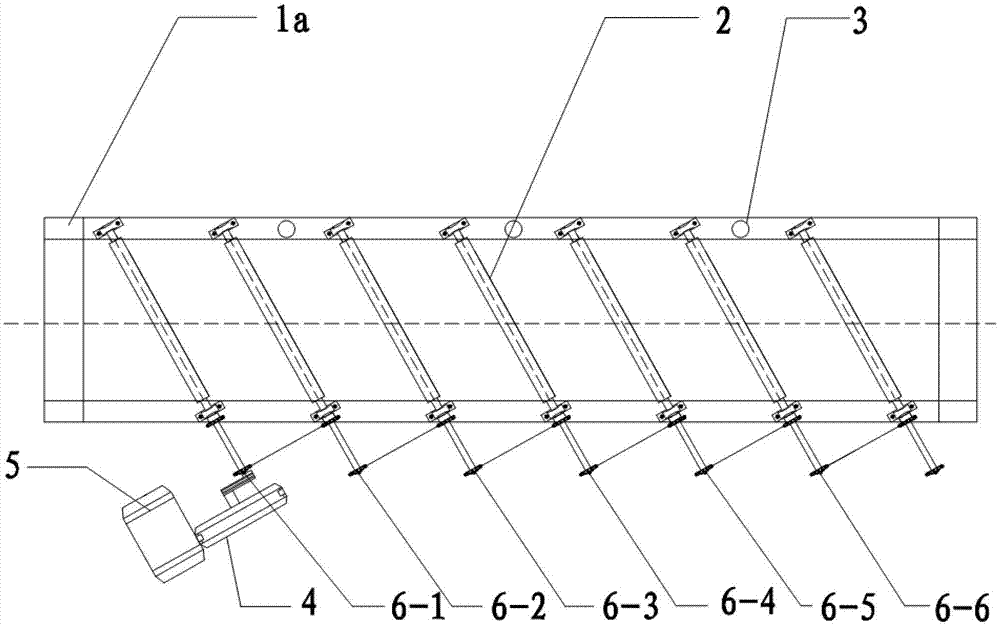

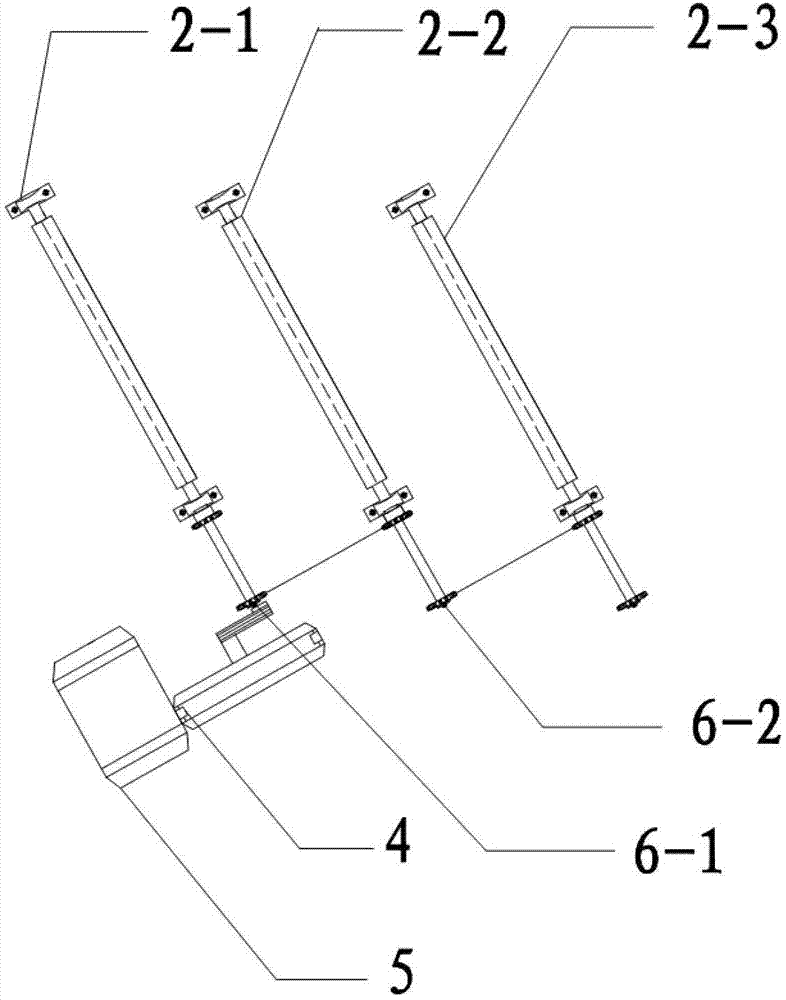

[0014] The present invention is a conveying roller table used for both corrugated steel plates and flat steel plates, comprising a roller table support, a roller shaft and a transmission mechanism, the roller shaft 2 is arranged obliquely relative to the two side frames 1a of the roller table support, arranged in parallel and at intervals, and the roller shaft 2 The two ends are respectively connected to the bearing seats 7 fixed on both sides of the roller table bracket through bearings; the transmission mechanism is composed of a motor, a gearbox, a sprocket, and a chain group, and the driving motor 5 and the reduction box 4 are fixed on the roller table bracket by bolts. On the pre-embedded foundation next to 1, the gearbox 4 is connected to the output of the motor 5, the output shaft of the gearbox 4 is connected to the first roller shaft 2-1 of the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com