A tubular belt conveyor

A technology for tubular belts and conveyors, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the unnatural and poor stress conditions of tubular belt hoops, special personnel are required to patrol and watch, and the tubular belt has high resistance to depression and other problems, to achieve the effect of small resistance, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention and concrete implementation will be further described:

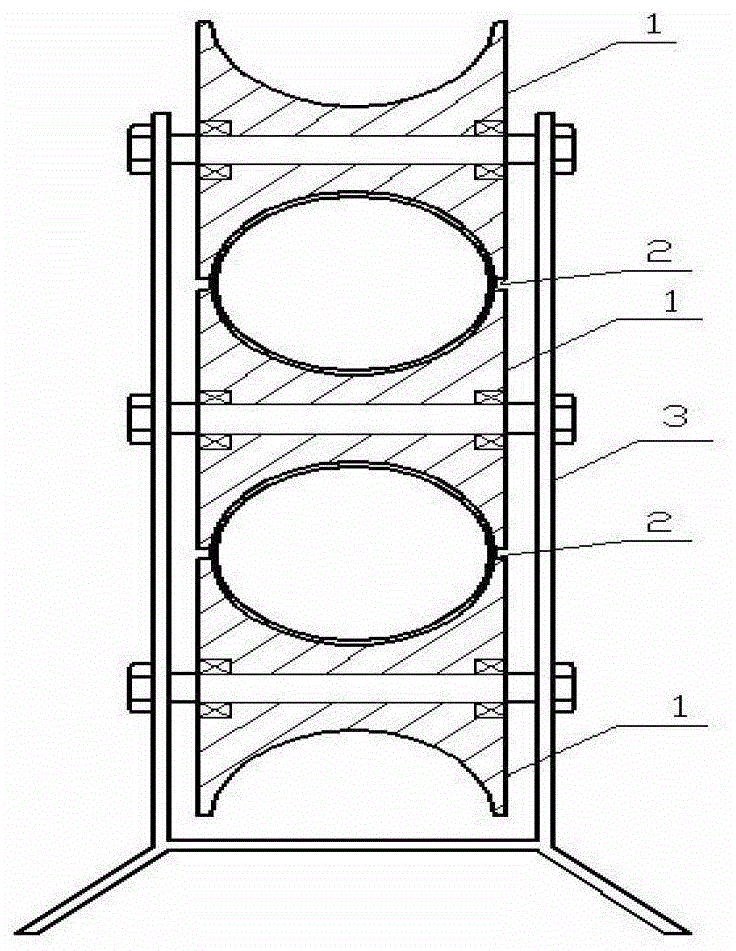

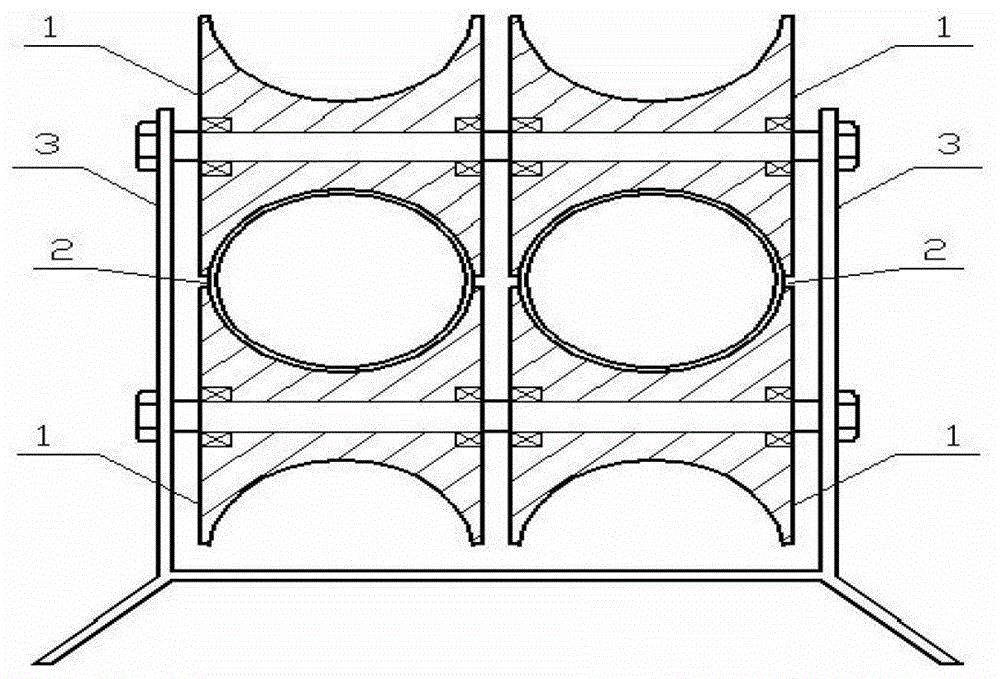

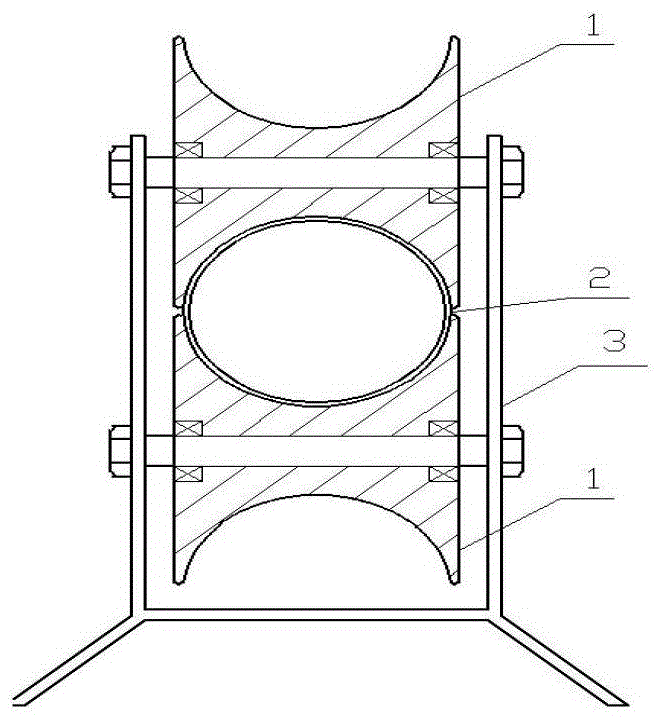

[0034] see figure 1 , a concave-curved idler 1 and an open idler bracket 3 are designed. The idler 1 is arranged and installed on the idler bracket 3 through the idler shaft in an up-middle-down manner. The bearing section of the tubular belt The upper and lower transmission channels are respectively hooped in the upper and lower transmission channels composed of three idlers 1, and the upper and lower transmission channels share the intermediate idler 1. The cross-sectional shape of the transmission channel is determined by the concave arc on the idler 1. Yes, this concave arc is comprehensively considered according to the straightness of the transmission route. For example, when there are frequent turns in the horizontal direction, the cross-sectional shape of the transmission channel should preferably be a vertical ellipse, and for example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com