A kind of preparation method of tert-butyllithium solution

A technology of tert-butyllithium and solution, applied in the field of basic chemical industry, can solve the problems of not getting the target product, low success rate, difficult to initiate reaction, etc., and achieve the effects of controlling the content of impurities, improving the success rate and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

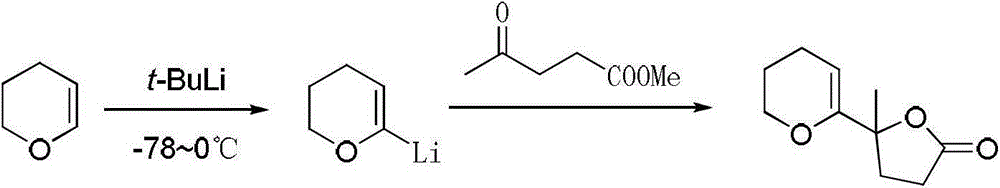

Image

Examples

Embodiment 1

[0026] Under argon protection, 21 g of 3% sodium-lithium alloy and 150 ml of high-boiling inert solvent (white oil) were added to a 1 L three-necked flask equipped with a high-speed stirrer. After replacing the air in the system with argon, slowly start stirring and heat to 200°C to completely melt the metal. At this time, the stirring speed rises to 1200r / min and the temperature reaches 210°C. Stir at high speed for 10 minutes at this temperature. Stop heating and stirring, and place the reaction bottle in a cold water bath to cool it down as soon as possible. After the temperature drops to 90°C, start stirring to further cool down to room temperature. The solvent was pressure filtered off under a flow of argon and washed three times with sodium-treated pentane. Finally, under the protection of argon, the solvent was evaporated to dryness, 470ml of dry pentane was added and heated to reflux the pentane, and 107ml (0.979mol) of chloro-tert-butane was added dropwise under vigor...

Embodiment 2

[0028] Under the protection of argon, add 21g of 3% sodium-lithium alloy and 150ml of high-boiling inert solvent (white oil) into a 1L three-neck flask equipped with a high-speed stirrer. After replacing the air in the system with argon, slowly start stirring and heat to 200°C to completely melt the metal. At this time, the stirring speed rises to 1200r / min and the temperature reaches 210°C. Stir at high speed for 10 minutes at this temperature. Stop heating and stirring, and place the reaction bottle in a cold water bath to cool it down as soon as possible. After the temperature drops to 90°C, start stirring to further cool down to room temperature. The solvent was pressure filtered under argon flow and washed three times with sodium treated n-hexane. Finally, under the protection of argon, the solvent was evaporated to dryness, 470ml of dry n-hexane was added and heated to reflux the n-hexane, and 107ml (0.979mol) of chloro-tert-butane was dripped under vigorous stirring. Th...

Embodiment 3

[0030] Under argon protection, add 21 g of lithium and 150 ml of high-boiling inert solvent (white oil) into a 1 L three-necked flask equipped with a high-speed stirrer. After replacing the air in the system with argon, slowly start stirring and heat to 200°C to completely melt the metal. At this time, the stirring speed increases to 1200r / min, and the temperature reaches 205°C. Stir at high speed for 10 minutes at this temperature. Stop heating and stirring, and place the reaction bottle in a cold water bath to cool it down as soon as possible. After the temperature drops to 90°C, start stirring to further cool down to room temperature. The solvent was pressure filtered under argon flow and washed three times with sodium treated n-hexane. Finally, under the protection of argon, the solvent was evaporated to dryness, 470ml of dry pentane was added and heated to reflux the pentane, and 107ml (0.979mol) of chloro-tert-butane was dripped under vigorous stirring. The reaction coul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com