Dynamic compactor and anti-impact luffing mechanism thereof

A luffing mechanism, anti-shock technology, applied in the direction of infrastructure engineering, construction, soil protection, etc., to reduce structural fatigue damage, small structural changes, improve work reliability and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

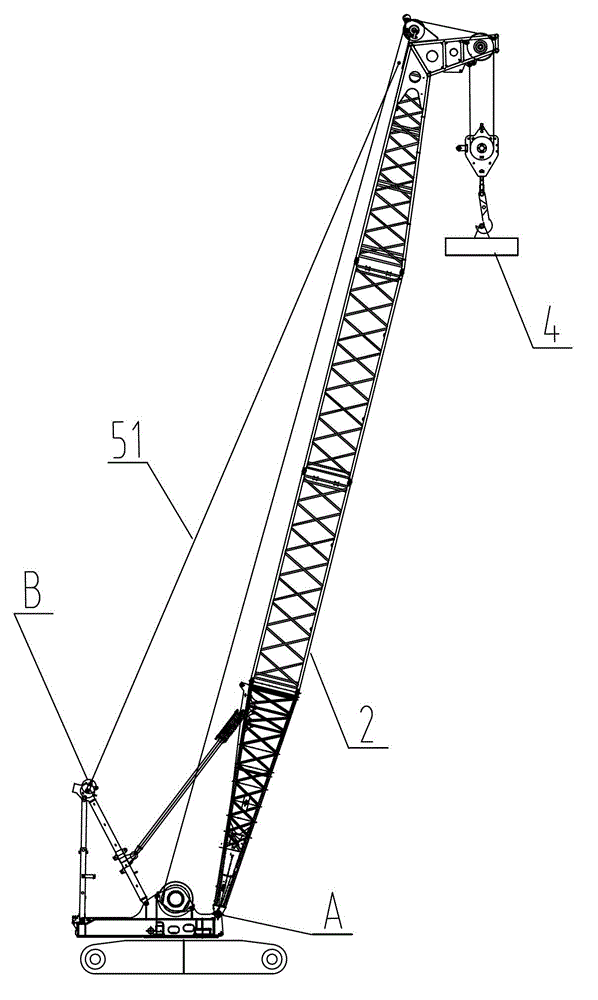

[0028] figure 1 Shown is a schematic diagram of the structure of the anti-shock luffing mechanism of an embodiment of the present invention. The anti-shock luffing mechanism of this embodiment includes a tension member whose end is connected to the arm head, and the tension member retracts the arm frame 2 under the action of the driving mechanism 1, so that the arm frame 2 raises and lowers the arm with the hinge point A as the center. arm (reference figure 2 ). The tension member can be an independent part or a combination of several parts.

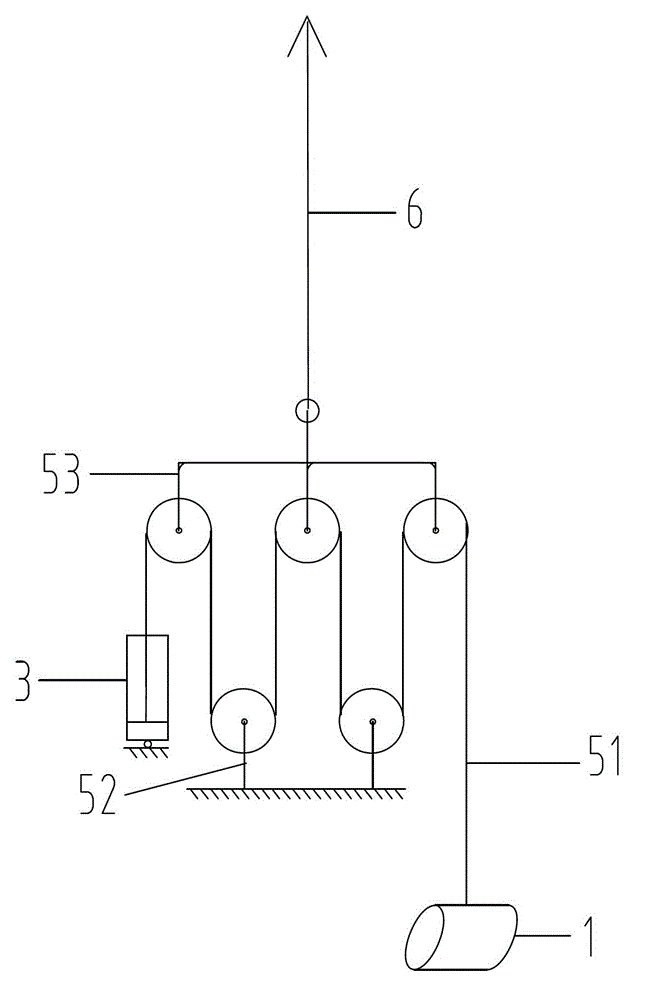

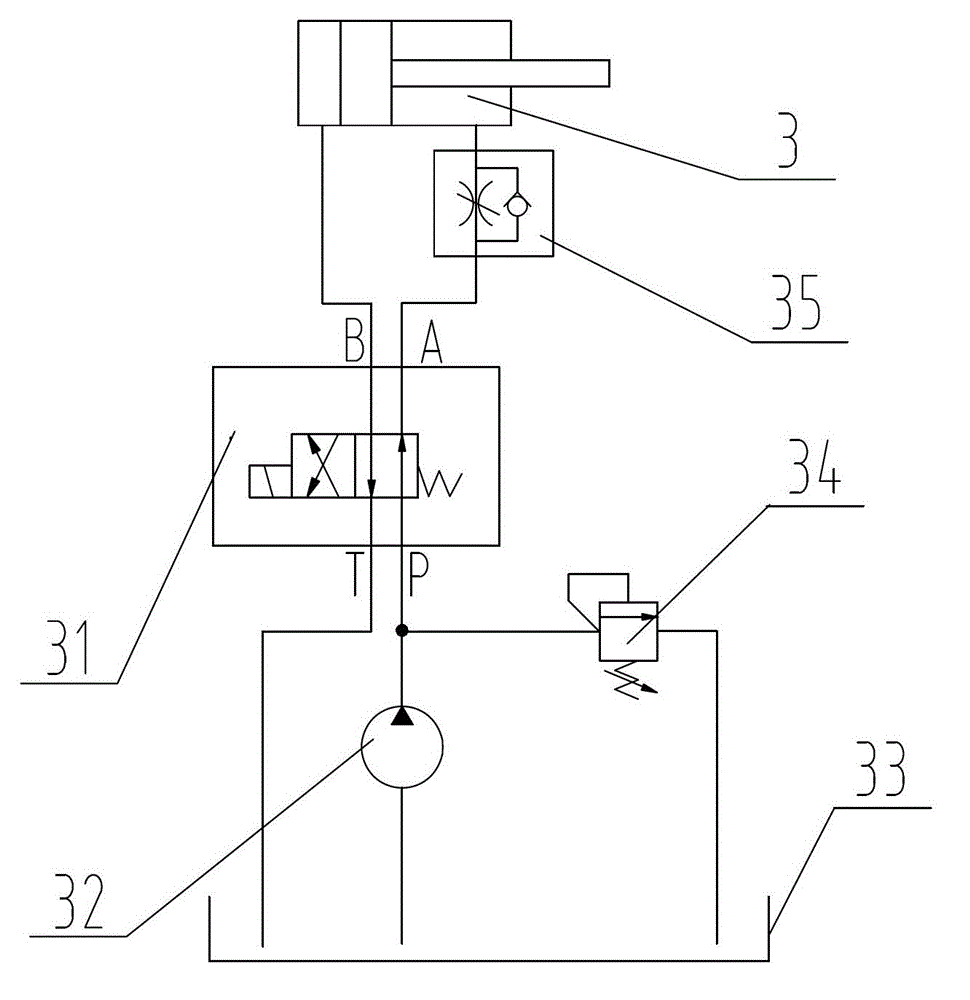

[0029] exist figure 1 In the shown embodiment, the anti-shock luffing mechanism is a hoist-driven luffing mechanism, including a rope 51, a fixed pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com