A round non-contact type protection mechanism for rubber base

A rubber bearing, non-contact technology, applied in the direction of building components, building structures, bridge parts, etc., can solve problems such as discounts and loss of function, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

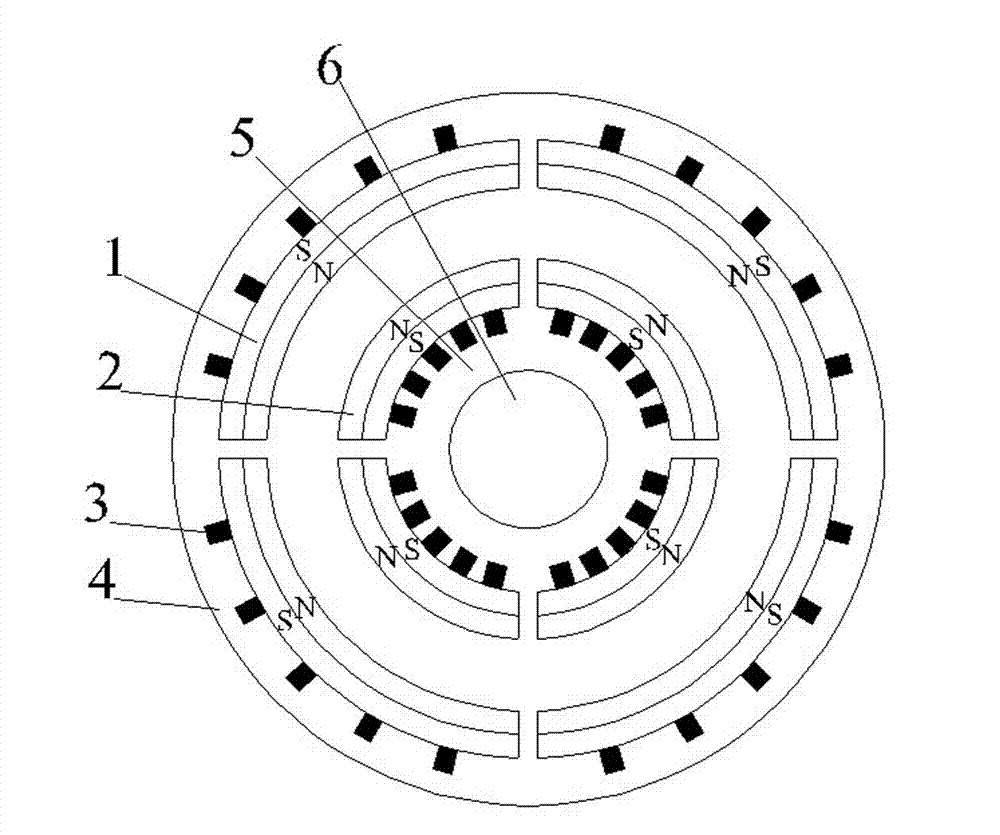

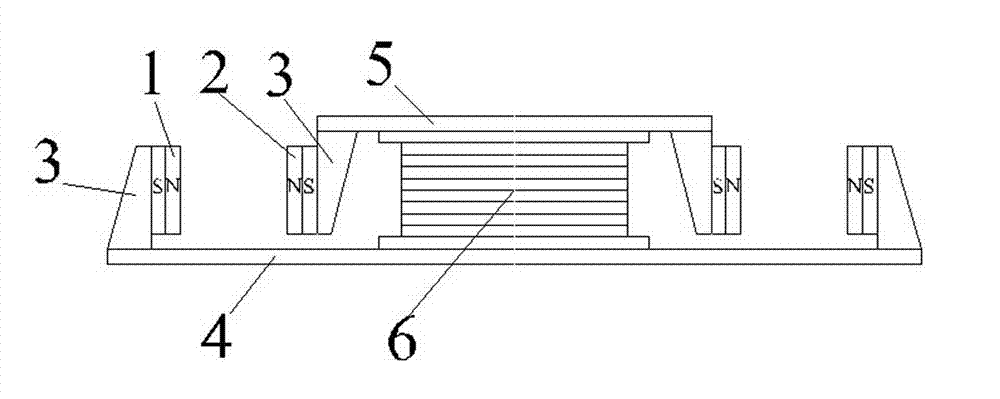

[0022] Such as Figure 1-6 As shown, a kind of circular non-contact rubber bearing protection mechanism of the present invention, its specific implementation is as follows:

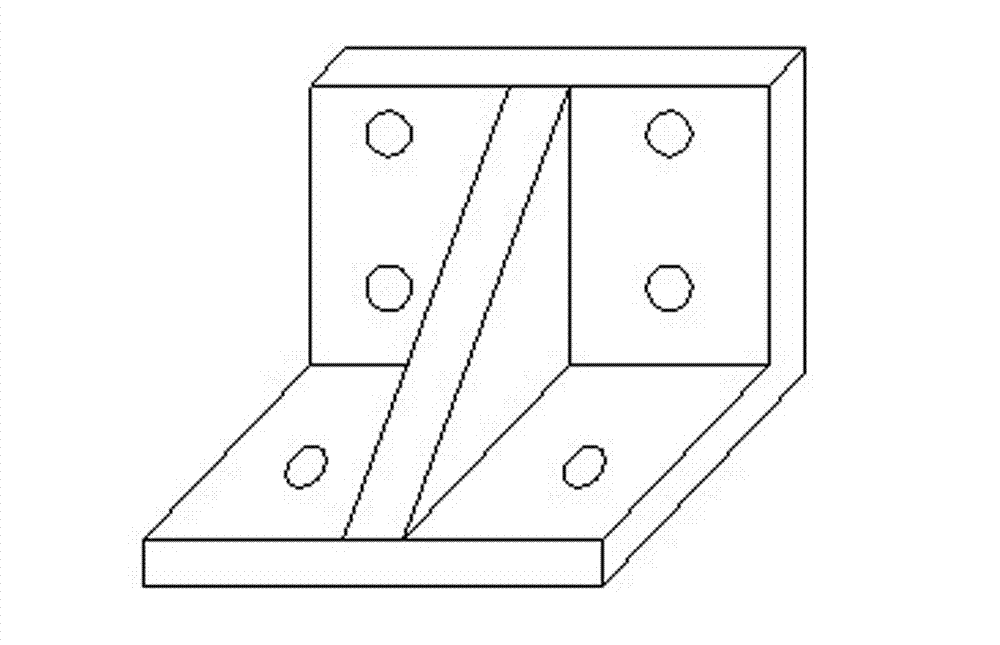

[0023] Both the outer magnet 1 and the inner magnet 2 have four arc-shaped magnets to form a circle, the N pole of the outer magnet 1 faces inward, and the N pole of the inner magnet 2 faces outward (or the S pole of the outer magnet 1 faces inward, and the N pole of the inner magnet 2 The S pole is outward), and there is a certain reserved distance between the inner and outer magnets; the outer magnet 1 is connected to the lower connecting plate 4 through the first reaction support 3, and the lower connecting plate 4 is connected to the lower steel plate of the rubber bearing 6; The inner magnet 2 is connected to the upper connection plate 5 through the second reaction force support 3 ; the upper connection plate 5 is connected to the upper steel plate of the rubber support 6 . All connections are bolte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com