Light guide column, light emitting structure and illumination device employing the same

A light-emitting structure and lighting device technology, applied in lighting devices, lighting and heating equipment, light guides of lighting systems, etc., can solve problems such as increasing the lighting angle and uneven brightness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

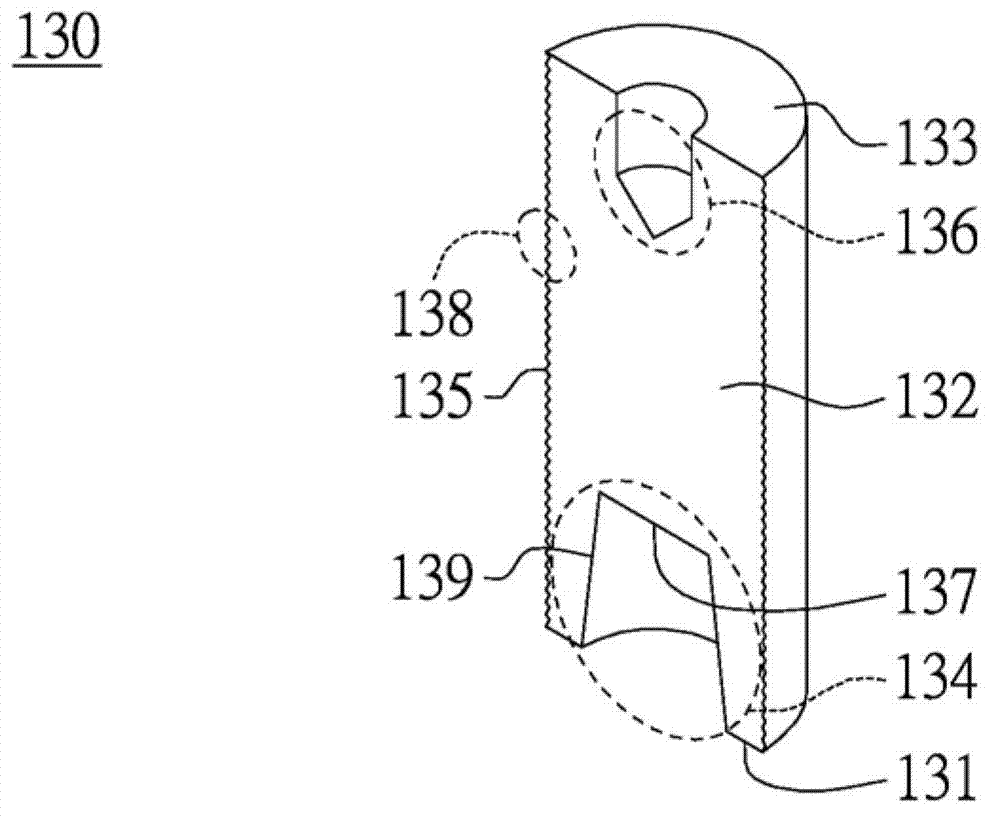

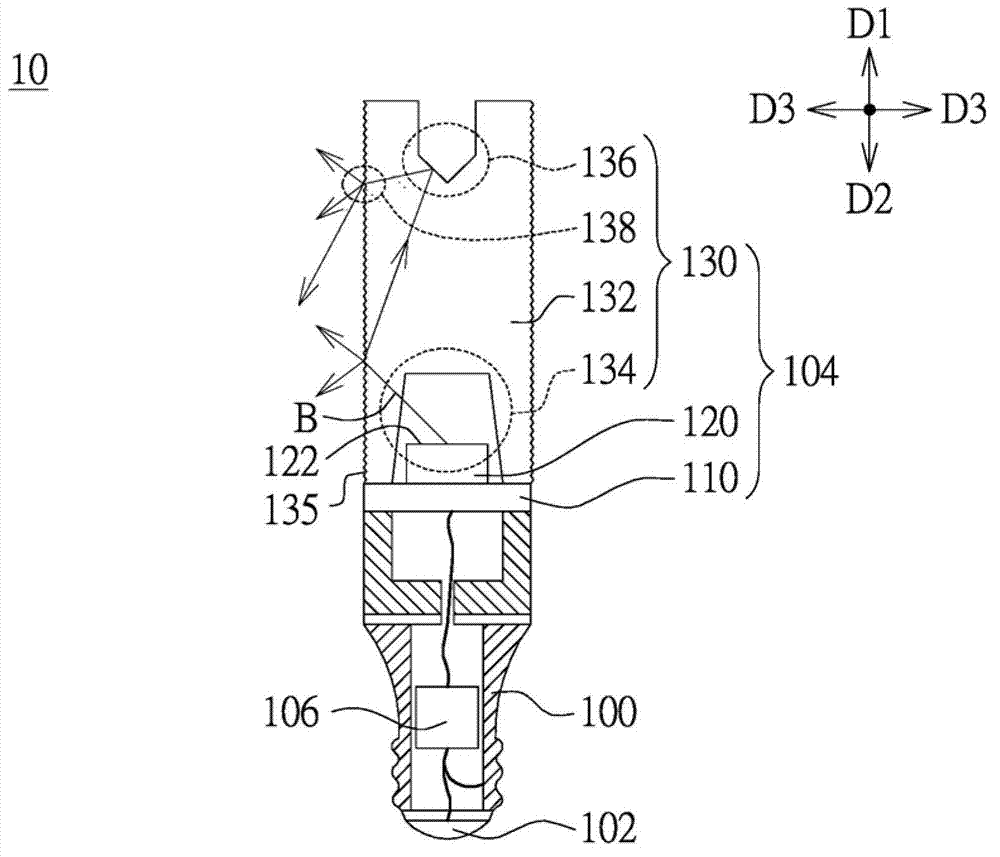

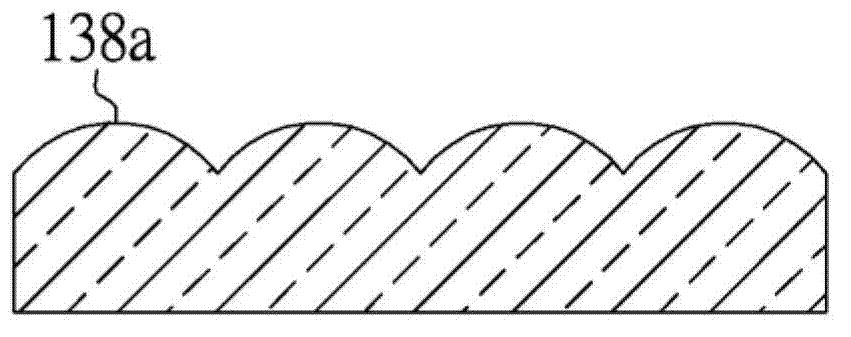

[0051] Please refer to figure 1 and figure 2 ,in figure 1 A schematic cross-sectional view of the light guide column 130 according to an embodiment of the present invention is shown, figure 2 A schematic diagram of the light emitting structure 104 and the lighting device 10 using a single light guide bar 130 is shown. The lighting device 10 includes a lamp holder 100 , an electrical connector 102 and a light emitting structure 104 . The lamp holder 100 has an accommodating space for setting a driving circuit module 106 , and the electrical connector 102 is located under the lamp holder 100 for receiving external power. The lamp holder 100 can be made of metal (such as copper or aluminum) or insulating and heat-dissipating material (such as plastic or ceramics). In this embodiment, the driving circuit module 106 can perform voltage transformation and AC / DC conversion, and the circuit board 110 is electrically connected to the electrical connector 102 through the driving c...

no. 2 example

[0056] Please refer to Figure 5 , which shows a schematic diagram of the light emitting structure 204 and the lighting device 20 using multiple rows of light guide rods 230 . The difference between this embodiment and the first embodiment is that the light emitting structure 204 and the illuminating device 20 include multiple rows of light guide columns 230 and multiple light emitting sources 220 . Each light guide column 230 is disposed on the circuit board 210 and correspondingly located above the light emitting source 220 for adjusting the light emitting angle of each light emitting source 220 . The driving circuit module 206 is connected to each light emitting source 220 via the circuit board 210 to control the light emitting sources 220 individually or simultaneously. The light emitting source 220 is, for example, a light emitting diode. Part of the light can be reflected by the reflective structure 236 to emit light toward the side surface 235 of the light guide body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com