Dual-mode compound shield testing machine

A testing machine and dual-mode technology, applied in the field of shield machines, can solve the problems of high manufacturing and testing costs, single function, inconvenient maintenance, etc., and achieve the effects of strong formation adaptability, broad application prospects and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

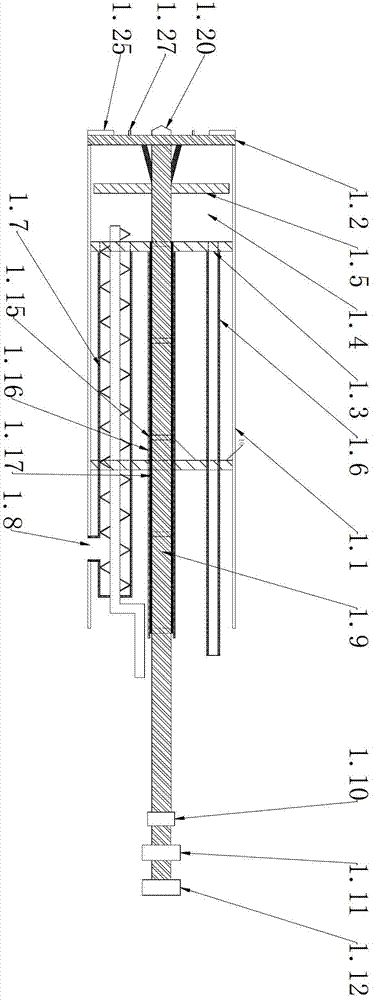

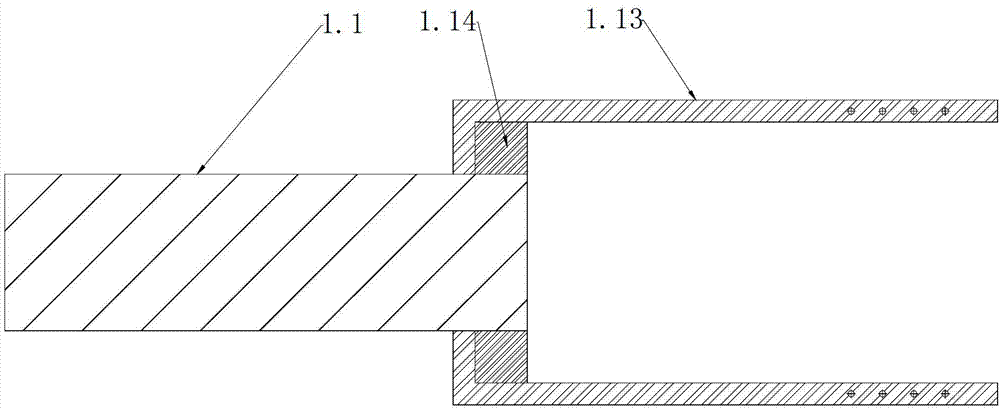

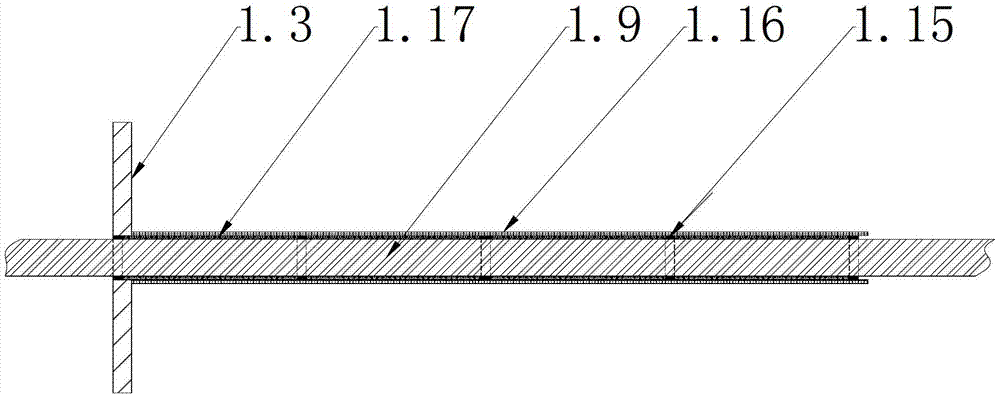

[0023] Such as figure 1 As shown, a dual-mode composite shield testing machine includes a shield testing machine 1, and the shield testing machine 1 includes a shield shell 1.1, and a cutter head 1.2 is installed on the front end of the shield shell 1.1, and the shield shell 1.1 The soil cabin 1.4 separated by the soil cabin partition 1.3 is arranged inside, and the soil cabin 1.4 is provided with a stirring rod 1.5 along the radial direction; The device 1.7 is connected with the soil chamber 1.4; the bottom of the shield shell 1.1 is provided with an excavation port 1.8, and the excavation port 1.8 is connected with the screw excavator 1.7; the cutter head 1.2 and the stirring rod 1.5 are driven by the driving shaft 1.9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com