Five-prevention interlocking mechanism

A five-proof interlocking and interlocking technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of large operating torque, long transmission distance, and inconvenient installation, and achieve small operating torque, short transmission distance, and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

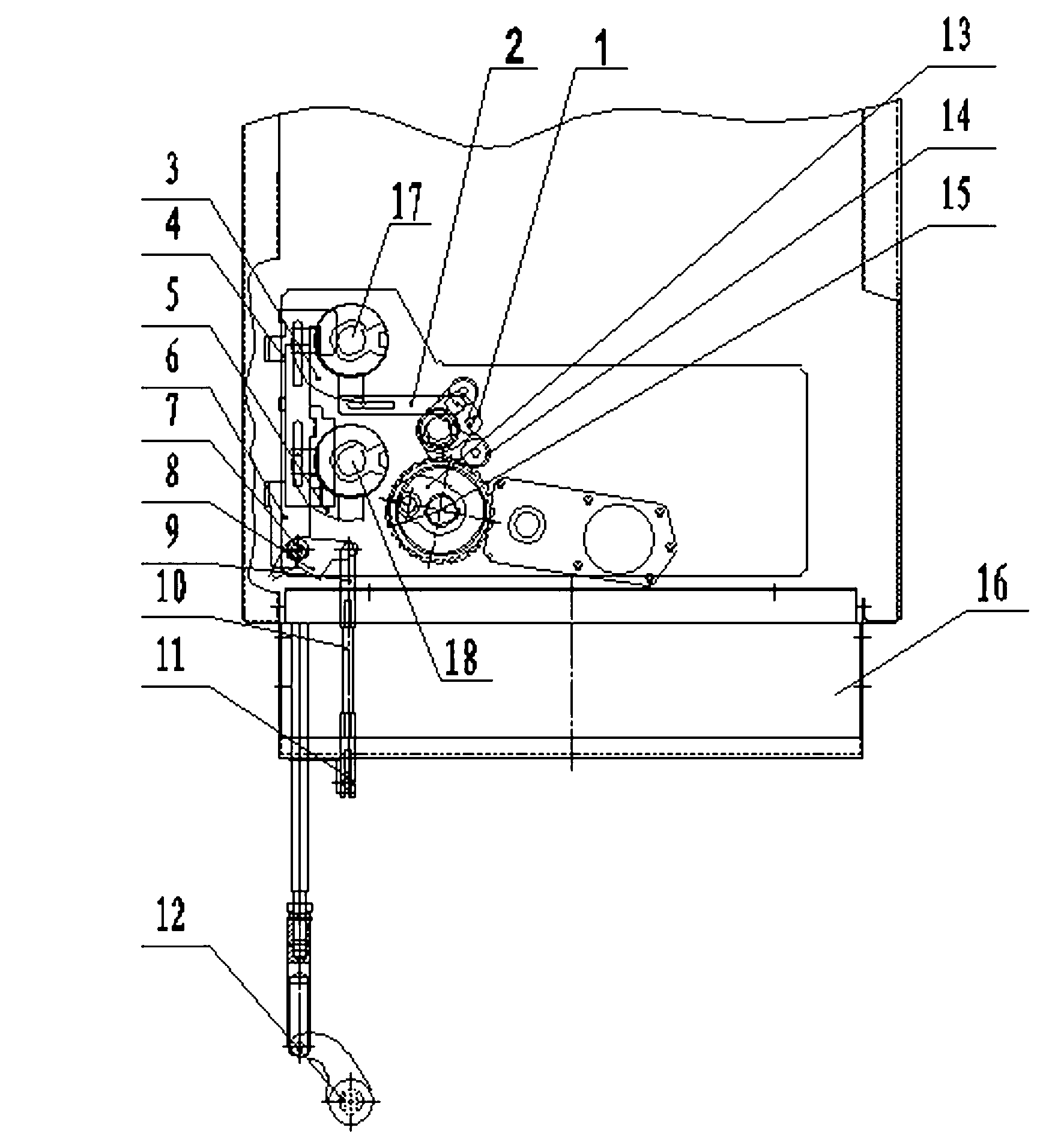

[0015] A five-proof interlocking mechanism includes a cabinet body 16, an isolation operation shaft 17, a grounding operation shaft 18, a lower door grounding interlocking unit, an isolated load interlocking unit, and an isolated grounding interlocking unit. The lower door grounding interlocking unit includes a lower door interlocking connecting rod 10, a grounding baffle 6, an interlocking connector 9, a lower door interlocking half shaft 7, a lower door locking shaft 12, a crank arm 8, and a hanging door Arm board 11. The door hanging arm plate 11 is connected to the lower end of the lower door interlock connection pull rod 10, and the upper end of the lower door interlock connection pull rod 10 is connected to the interlock connector 9. Door interlock axle 7. The grounding baffle 6 is movably connected to the outside of the front end of the grounding operation shaft 18. When the door-hanging arm plate 11 is not hung on the door, the grounding baffle 6 is blocked in front o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com