Convenient-to-produce lamp bead

A lamp bead and lamp pin technology, applied in electrical components and other directions, can solve the problems of low production efficiency, inconvenient processing, low product qualification rate, etc., and achieve the effect of low cost and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

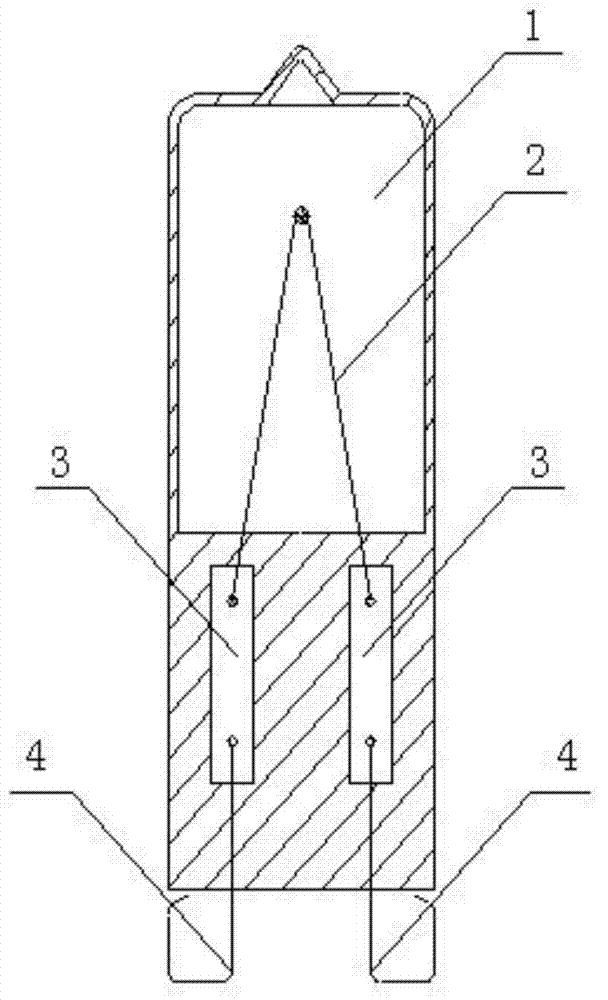

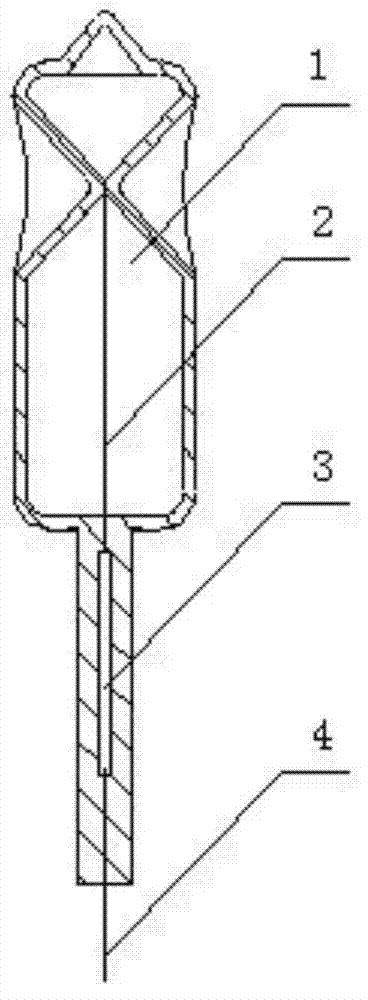

[0010] Such as figure 1 , figure 2 As shown, the easy-to-process lamp bead described in this embodiment includes an outer bulb 1, a filament 2, a molybdenum sheet 3, and a lamp pin 4; the molybdenum sheet 3 has two pieces, and the lamp pin 4 has two The upper side walls of the outer bulb 1 are recessed to form a connection point, the filament 2 is hung on the connection point, and the two ends of the filament 2 are connected to one end of the lamp pin 4 through the molybdenum sheet 3, and the lamp pin The other end extends out of the outer bulb and bends into Shape, the size and shape of the two lamp pins are the same, and the two lamp pins are arranged symmetrically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com