Lithium-ion power battery and quick charging electric automobile with same

A power battery and lithium-ion technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of improved safety, stable discharge voltage, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

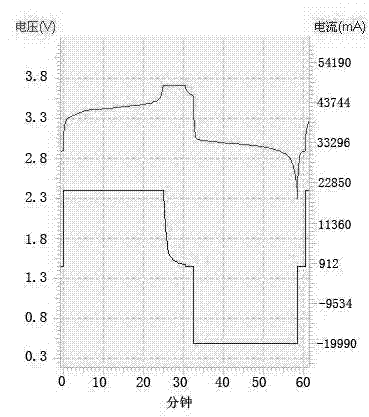

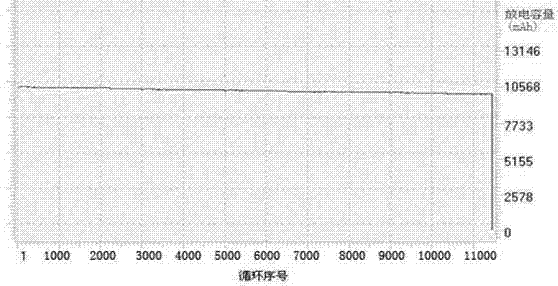

Image

Examples

Embodiment 1

[0044] The positive active material includes: 91% lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ), 5% PVDF, 4% SP;

[0045] The negative electrode active material includes: 90% lithium titanate (Li 4 Ti 5 0 12 ), 5% PVDF, 5% SP;

[0046] Above-mentioned lithium-ion battery preparation steps are as follows:

[0047] Lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ), PVDF and SP are dissolved in NMP, and the positive electrode slurry is made through a slurry mixing machine;

[0048] Lithium titanate (Li 4 Ti 5 0 12 ), PVDF and SP are dissolved in NMP, and the negative electrode slurry is made by a mixing machine;

[0049] Both the positive and negative electrode current collectors are made of aluminum foil, and the aforementioned positive and negative electrode slurry is uniformly coated on the aluminum foil through a coating machine and wound into a roll, and then baked and rolled to make positive and negative electrode sheets respectively;

[0050] Afte...

Embodiment 2

[0056] The positive active material includes: 96% lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ), 3% PVDF, 1% KS-6;

[0057] The negative electrode active material includes: 96% lithium titanate (Li 4 Ti 5 0 12 ), 3% PVDF, 1% Ketjen Black;

[0058] Above-mentioned lithium-ion battery preparation steps are as follows:

[0059] Lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ), PVDF, KS-6, dissolved in NMP, and made into positive electrode slurry by mixing machine;

[0060] Lithium titanate (Li 4 Ti 5 0 12 ), PVDF, Ketjen black, dissolved in NMP, and made into negative electrode slurry by mixing machine;

[0061] Both the positive and negative electrode current collectors are made of aluminum foil, and the aforementioned positive and negative electrode slurry is uniformly coated on the aluminum foil through a coating machine and wound into a roll, and then baked and rolled to make positive and negative electrode sheets respectively;

[0062] After the po...

Embodiment 3

[0068] The positive active material includes: 86% lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ), 6% PVDF, 5% SP, 3% KS-6;

[0069] The negative electrode active material includes: 86% lithium titanate (Li 4 Ti 5 0 12 ), 6% PVDF, 6% SP, 2% carbon

[0070] nanotube;

[0071] Above-mentioned lithium-ion battery preparation steps are as follows:

[0072] Lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ), PVDF, SP, KS-6 are dissolved in NMP, and the positive electrode slurry is made into a positive electrode slurry through a mixing machine;

[0073] Lithium titanate (Li 4 Ti 5 0 12 ), PVDF, SP, carbon nanotubes, dissolved in NMP, and made into negative electrode slurry by mixing machine;

[0074] Both the positive and negative electrode current collectors are made of aluminum foil, and the aforementioned positive and negative electrode slurry is uniformly coated on the aluminum foil through a coating machine and wound into a roll, and then baked and rolled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com