Electric pressure cooker

A technology of electric pressure cooker and pressure valve, applied in the field of pressure cooker, can solve the problems of not being able to automatically exhaust to control boiling and non-boiling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

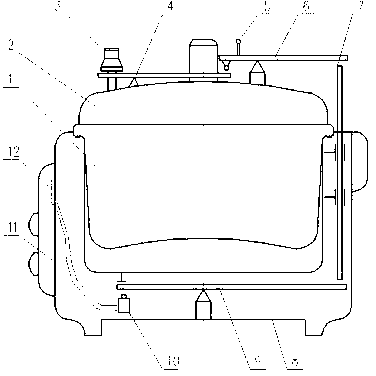

[0013] In the figure, the present invention includes a pot 1, a pot cover 2, a pot cover 8, and an electric heating program board 11. On the pot cover 2, a first lever 4 and a second lever 6 are sequentially installed, and the left end of the first lever 4 is installed on the Below the pressure valve 3 on the pot cover 2, the pressure valve 3 is in a free-falling sealed state, and the left end of the second lever 6 is above the right end of the first lever 4; a third lever 9 and a solenoid valve 10 are installed on the inner bottom of the pot cover 8 , the electromagnetic valve 10 is installed near the left end of the third lever 9; a transmission rod 7 is installed on the side of the pot cover 8, the upper end of the transmission rod 7 is below the right end of the second lever 6, and the lower end of the transmission rod 7 is at the right end of the third lever 9 Above, a timer 12 is added on the electric heating program board, and the solenoid valve 10 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com