Device for filtering cooling liquid for machining

A filtering device and machining technology, applied in the field of cooling liquid processing equipment for machining, can solve the problems of high cost, affect metal machining, increase the production cost of enterprises, etc., and achieve reasonable equipment design, high degree of reuse, and removal of Complete effect of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

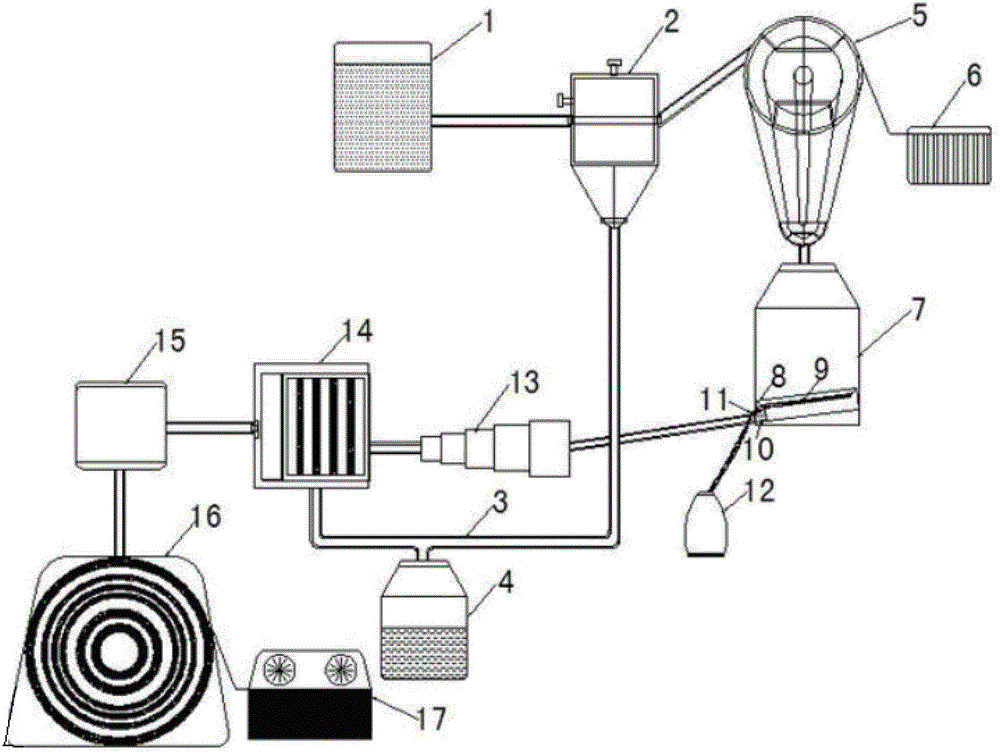

[0009] The specific implementation mode adopted in the present invention is: first pass the cooling liquid in the cooling liquid tank 1 through the gravity separator 2 to remove most of the floating oil in the cooling liquid, the cooling liquid tank 1 is connected with the gravity separator 2, and the floating oil passes through The oil collection pipe 3 is collected in the oil collection tank 4, and the gravity separator 2 and the oil collection tank 4 are connected through the oil collection pipe 3; the gravity separator 2 is connected with a funnel-type drum 5, and the cooling liquid is connected with the motor 6, and braked by the motor 6 The funnel-type drum 5 rotates and speeds up the coolant to the high-pressure high-temperature furnace 7, the funnel-type drum 5 is connected to the high-pressure high-temperature furnace 7, and the coolant flows through the high-pressure high-temperature furnace 7 in an S-shape from top to bottom, and passes through the high-pressure high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com