Filling device for solid tires

A filling device, a technology for solid tires, applied in the tire field, can solve the problems of slow mold clamping, tight time, low production efficiency and product yield, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

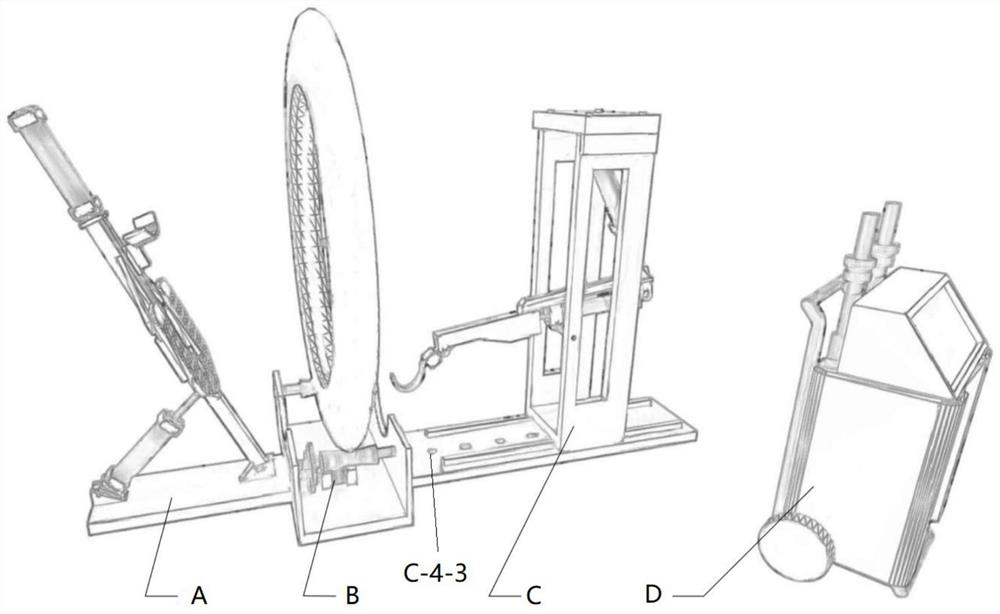

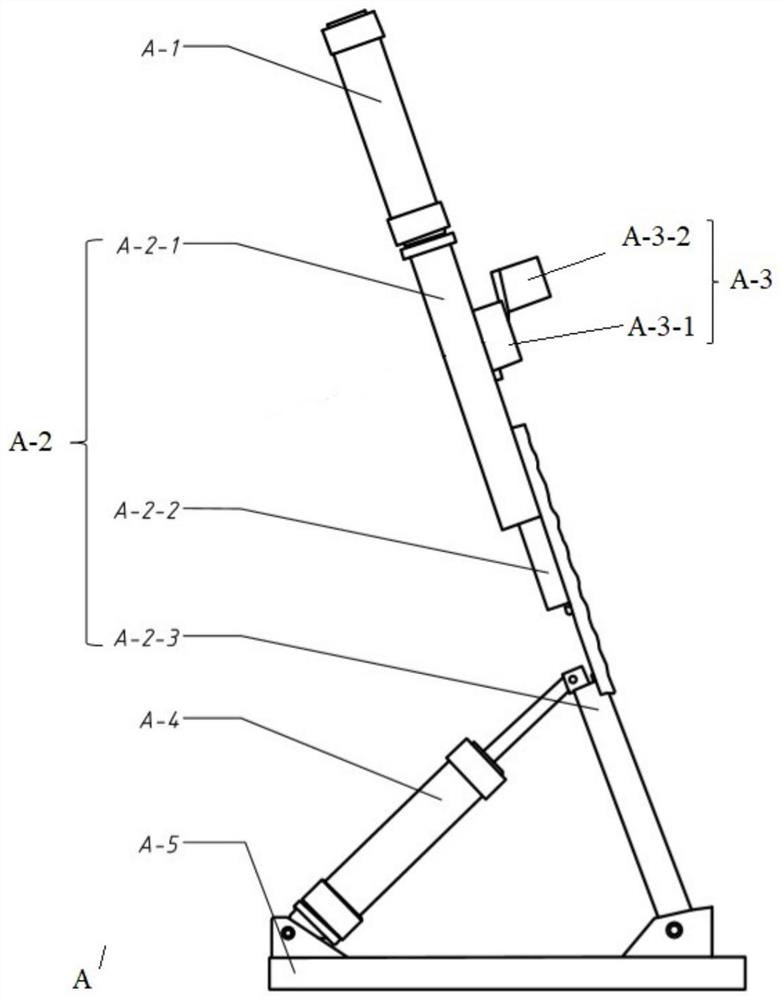

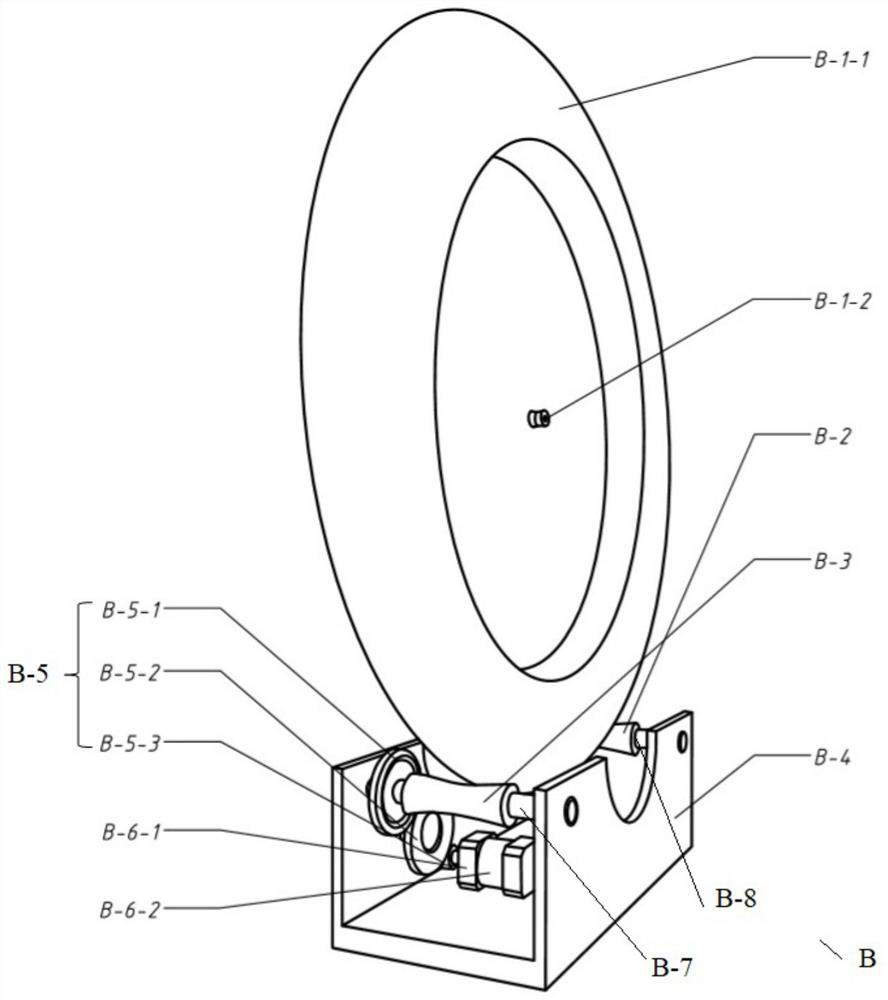

[0031] Such as figure 1 , 2 , Shown in 3 and 4, a solid tire filling device, the solid tire includes a wheel hub, a wheel shaft B-1-2 located at the center of the wheel hub, an inner tube set on the outside of the wheel hub and a cover tire B-1-2 set on the outside of the inner tube 1. The device includes a control system and a tire clamping tool A, a tire rotator B, a foam filler injection robot system C and a foam material generating system that are electrically connected to the control system, the foam material generating system carries a control system, and the tire The clamping tool A, the tire rotator B and the foam filler injection manipulator system C are set up sequentially. The tire clamping tool A includes a first base A-5 and a pendulum rotatably arranged on the first base A-5. The rod bracket assembly and the wheel shaft fixing claw assembly which is movably arranged on the swing rod bracket assembly and used to fix the wheel shaft B-1-2, the tire rotator B inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com