A kind of recovery method and its product and application of waste after organic waste water treatment by ldh

A technology of organic waste water and recovery method, applied in the fields of botany equipment and methods, water pollutants, chemical instruments and methods, etc., can solve the problem of inability to achieve complete regeneration of adsorbents, low added value of adsorbents, secondary pollution of adsorbents, etc. problem, to achieve better effect, high degree of reuse, and lower emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

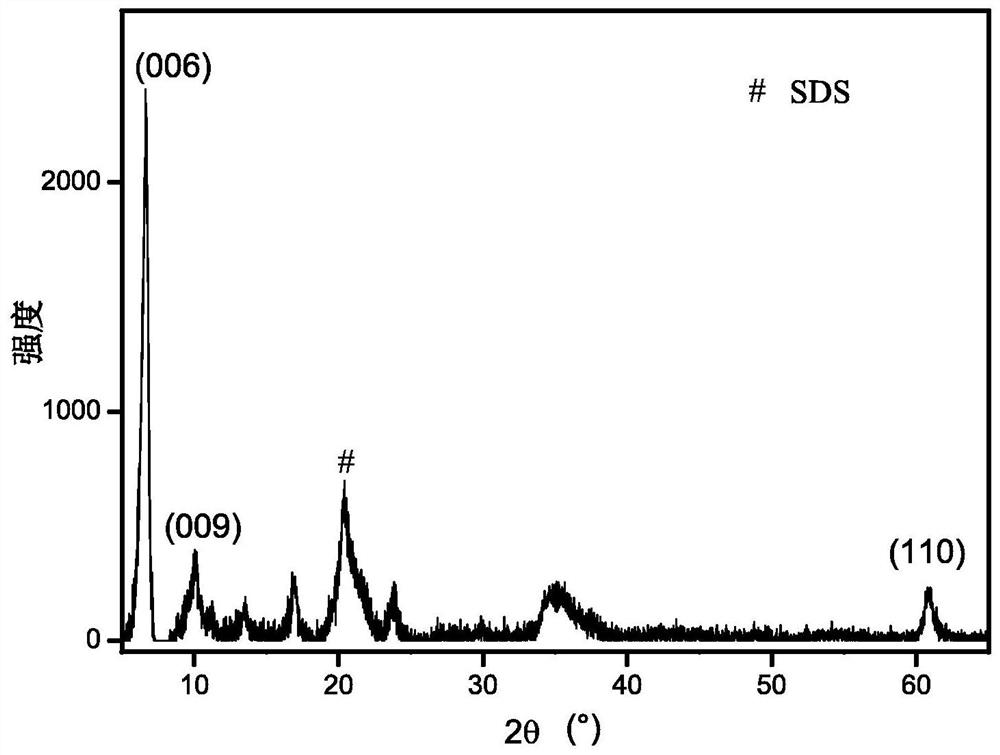

[0031] (1) In the printing and dyeing wastewater treatment project, magnesium aluminum hydrotalcite is added to the reaction tank to absorb its organic pollutants, and the precipitate after the adsorption is separated from solid to liquid, and then dried by centrifugal dehydration, heating and drying, etc. Part of the solid O-LDH waste can be taken for X-ray diffraction (XRD) to obtain figure 1 Diffraction pattern of the obtained material composition, phase structure, morphology and other information, it can be clearly seen that the organic pollutant SDS has successfully intercalated into the LDH laminates;

[0032] (2) Import the dried O-LDH into a high-temperature-resistant porcelain container, and carry out cracking in a tube furnace at a constant temperature of 500°C. The tube furnace program is set as follows: the initial temperature of the first stage is 20°C, and after Rise from 20°C to 200°C in 20 minutes; in the second stage, increase the temperature from 200°C to 500...

Embodiment 2

[0035] (1) In the tannery wastewater treatment project, magnesium aluminum hydrotalcite is added to the reaction tank to absorb its organic pollutants, and the precipitate after the adsorption is separated from solid to liquid, and then dehydrated by centrifugal dehydration, heating and drying to obtain Dried solid O-LDH waste;

[0036] (2) Import the completely dried O-LDH into a high-temperature-resistant porcelain container, and crack in a tube furnace at a constant temperature of 700°C. The program is set as: T 1起始 = 30°C, after 25min from 30°C to 250°C, in the second stage at a rate of 10°C / min from 250°C to 700°C for 240min, then with V 降 =15°C / min from 700°C to 340°C, and finally cooled to room temperature naturally.

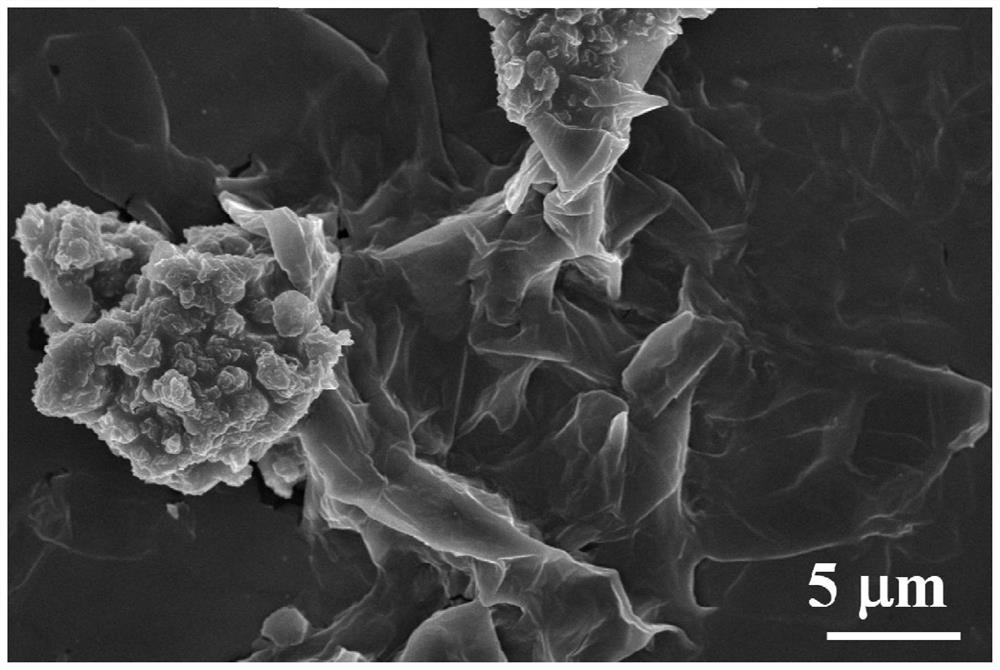

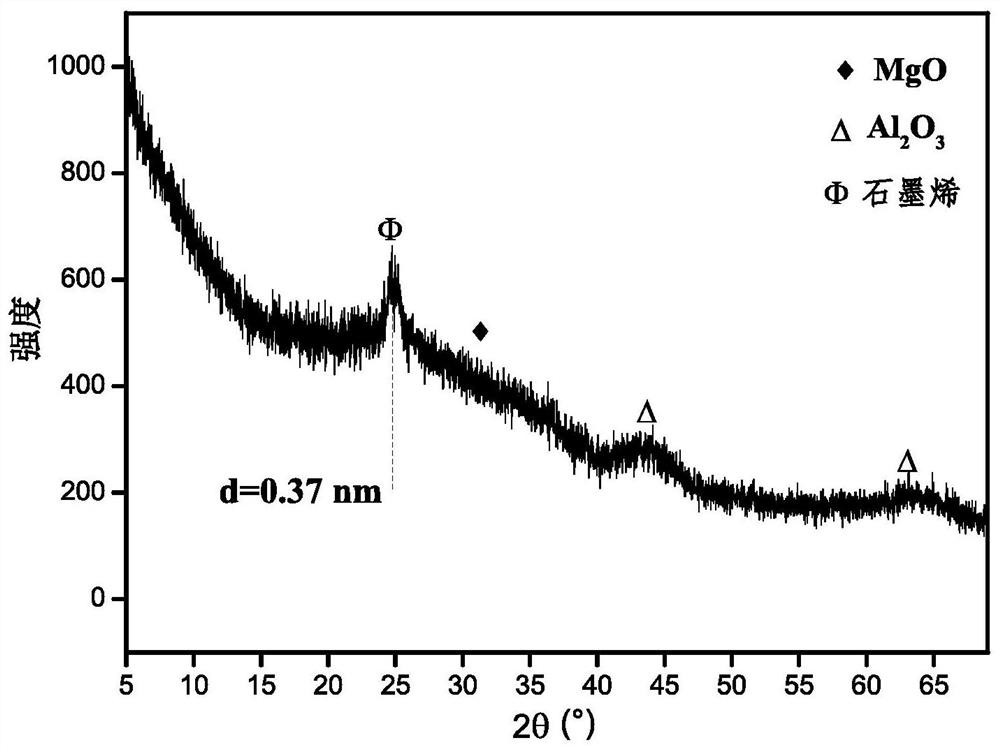

[0037] Carry out X-ray diffraction (XRD) and scanning electron microscope (SEM) analysis to the product through step (2), draw its such as Figure 4 The XRD patterns shown and as Figure 5 From the SEM spectrum shown, it can be known that O-LDH will be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com