Two-phase porous drainage nozzle in cement furnace gas denitration system

A kiln and flue gas technology, which is applied in the directions of injection device, liquid injection device, and dispersed particle separation, can solve the problems of uneven injection of reducing agent and poor atomization effect, and achieves improved particle size range, increased uniformity, Reasonable and compact effect of structural dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further elaborated below in conjunction with the accompanying drawings.

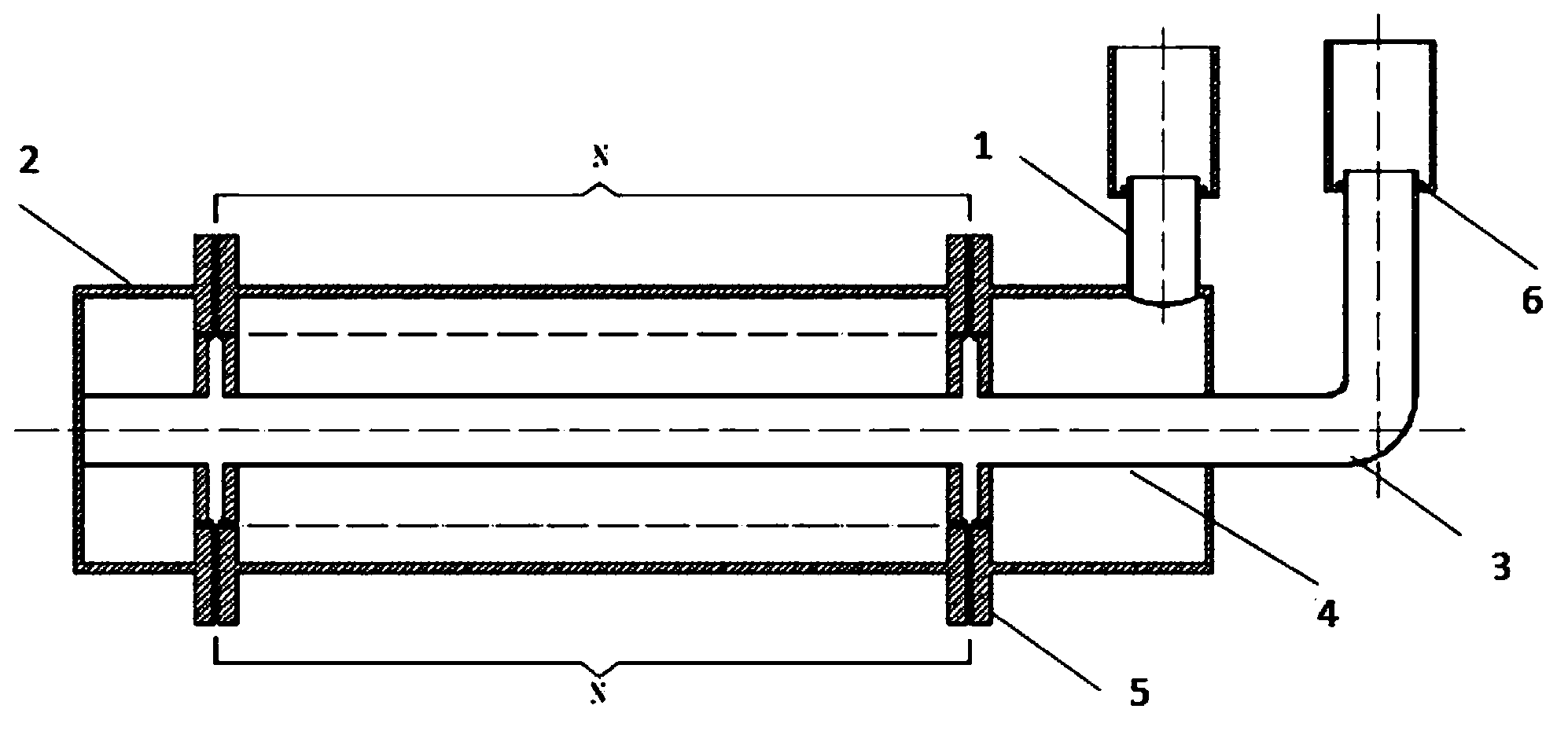

[0012] Such as figure 1 As shown, the present invention comprises a liquid supply pipe 1, a liquid flow pipe 2, an air supply pipe 2, a compressed air pipe 4, an air injection nozzle 5, and a ferrule 6; the ammonia solution flows into the liquid supply pipe 1 from an external pipeline, and then enters the cylinder The body-shaped liquid flow pipe 2 plays the role of liquid storage for the air injection nozzle to provide ammonia water. The compressed air enters through the air supply pipe 3, and the air pressure is stabilized in the compressed air pipe 4. The air injection nozzle 5 and the compressed air pipe Outflow from the interface of 4, the diameter of the air hole in the air ejection nozzle 5 becomes smaller and the air flow velocity increases, causing the static pressure of the air flow to decrease and guide the ammonia water in the liquid flow pipe to enter the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com