Material hitting device for red punching mould

A technology of mold and red punch, which is applied in the field of red punch die feeding device, can solve the problems of increased processing workload, product surface bruise, easy sticking of punch, etc., to prevent two blanks from superimposed stamping, safe and reliable The effect of working environment and protecting long-term safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

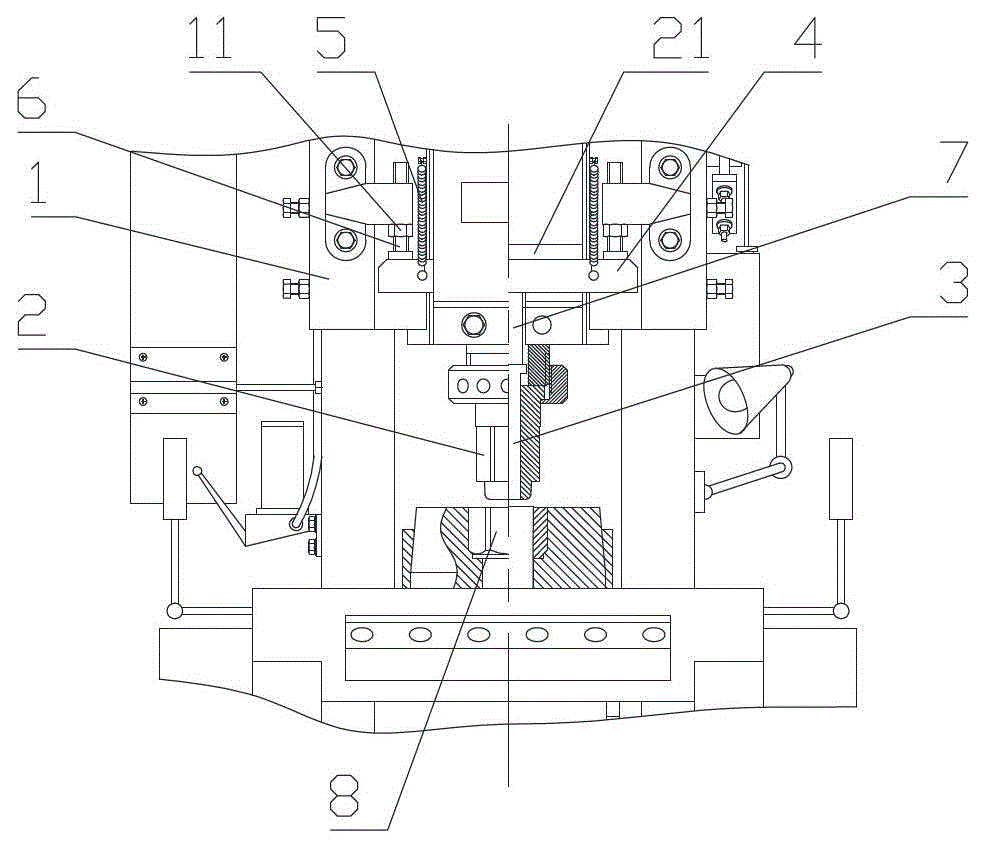

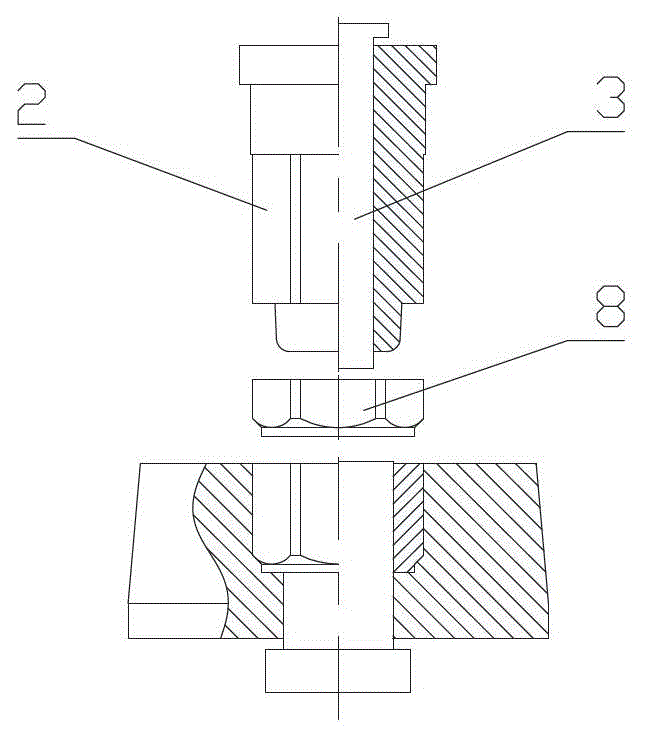

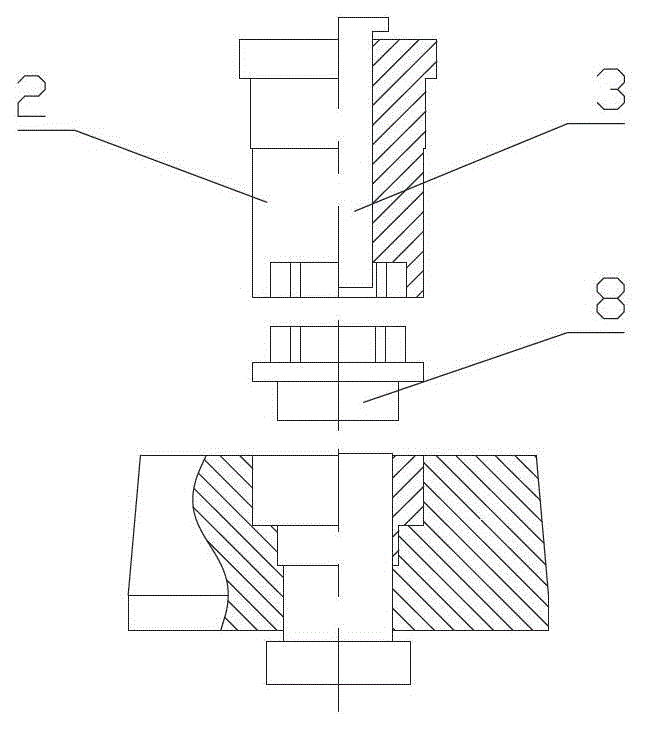

[0020] Such as figure 1 Shown is an embodiment of the present invention, a kind of punching device for a red punching die, including a punch 2 arranged on a fuselage 1, and a punching rod 3 is arranged in the punching head, and the punching rod can be opposite to each other. The punch moves up and down, and there is a guide structure on the fuselage, which can retract the punching rod into the punch when stamping the blank 8, and make the punching rod extend out of the punch to push the blank away when the blank is demolded. shower. The guide structure includes a cross arm 4 which is arranged on the punch and is connected to the punching rod for transmission, and an elastic member 5 which is arranged on the punch and keeps pulling the cross arm upward. The fuselage is provided with a guide column 6, so The lower end of the guide column is located on the moving track of the cross arm and resists the cross arm when the cross arm is pulled and moves upward. The optimal state is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com