Verticality adjusting device for rear baffles of hydraulic swing plate shears

A technology of adjusting device and backgauge, which is applied to the accessories of shearing machine, shearing device, metal processing equipment, etc., can solve the problems of difficult to guarantee product quality, difficult adjustment, slow speed, etc. The effect of eliminating hidden dangers and strong system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

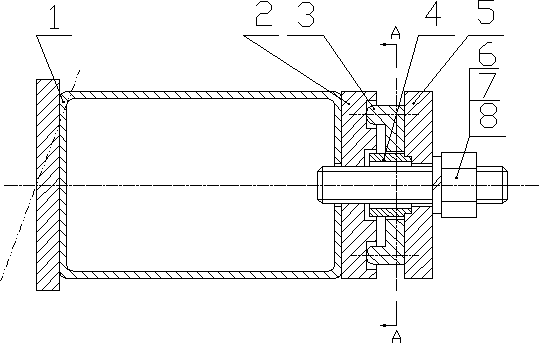

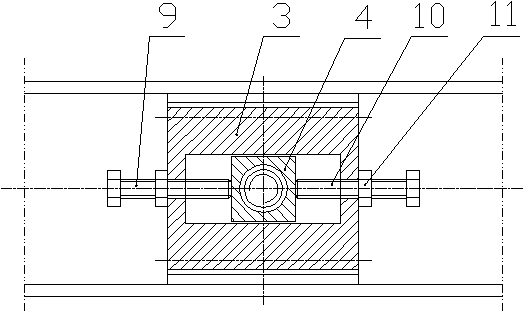

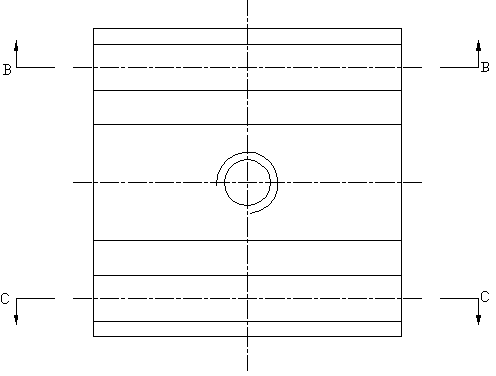

[0017] from figure 1 , figure 2 It can be seen that the adjustment device for the verticality of the rear baffle of the hydraulic pendulum shearing machine of the present invention includes a rear baffle body 1, a rear baffle support vertical plate 5, and a central connecting bolt 6, and is characterized in that it also includes Fixed adjustment plate 2, sliding adjustment plate 3, center block 4, left adjustment bolt 9, right adjustment bolt 10, tightening nut 11; Set forward in turn, the fixed adjustment plate 2 is welded on the rear baffle body 1; the center block 4 is placed in the chute at the center of the fixed adjustment plate 2 and the sliding adjustment plate 3, and is connected with the rear baffle bracket vertical plate 5 The holes of the fixed adjustment plate 2 are closely matched; the central connecting bolt 6 is matched with the threaded hole of the fixed adjustment plate 2, and the fixed adjustment plate 2 and the sliding adjustment plate 3 are closely fitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com