Printing tower for rotary offset printing machine

A technology of printing towers and printing machines, applied in the field of printing towers, can solve problems such as inability to obtain printing units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

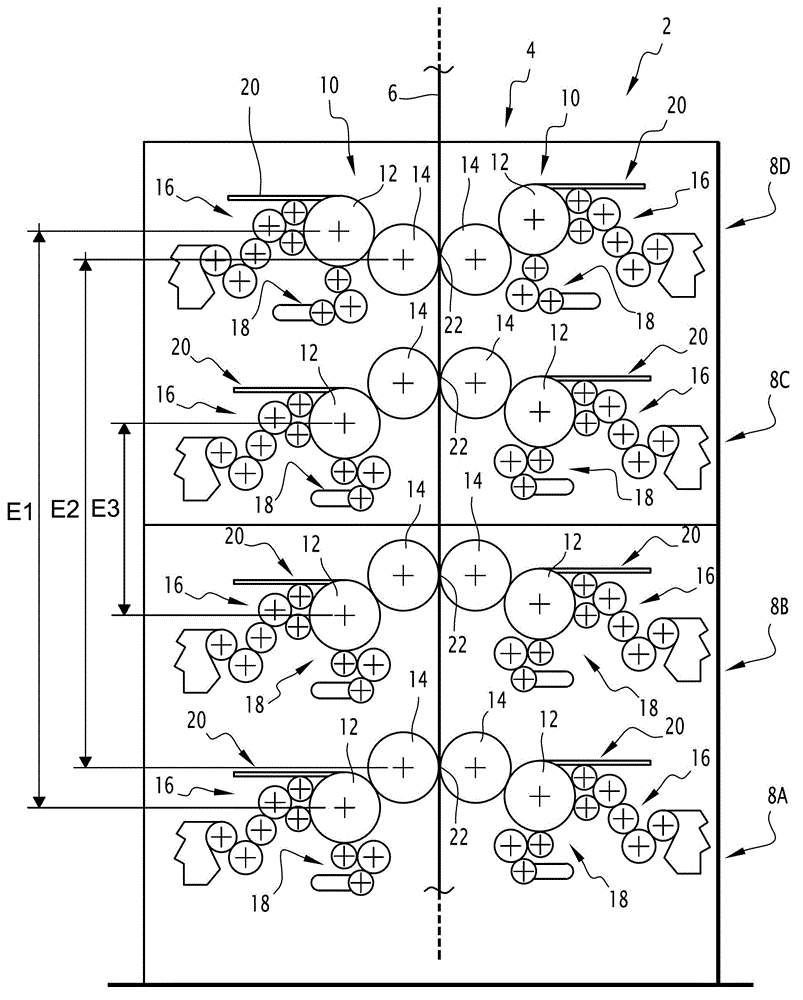

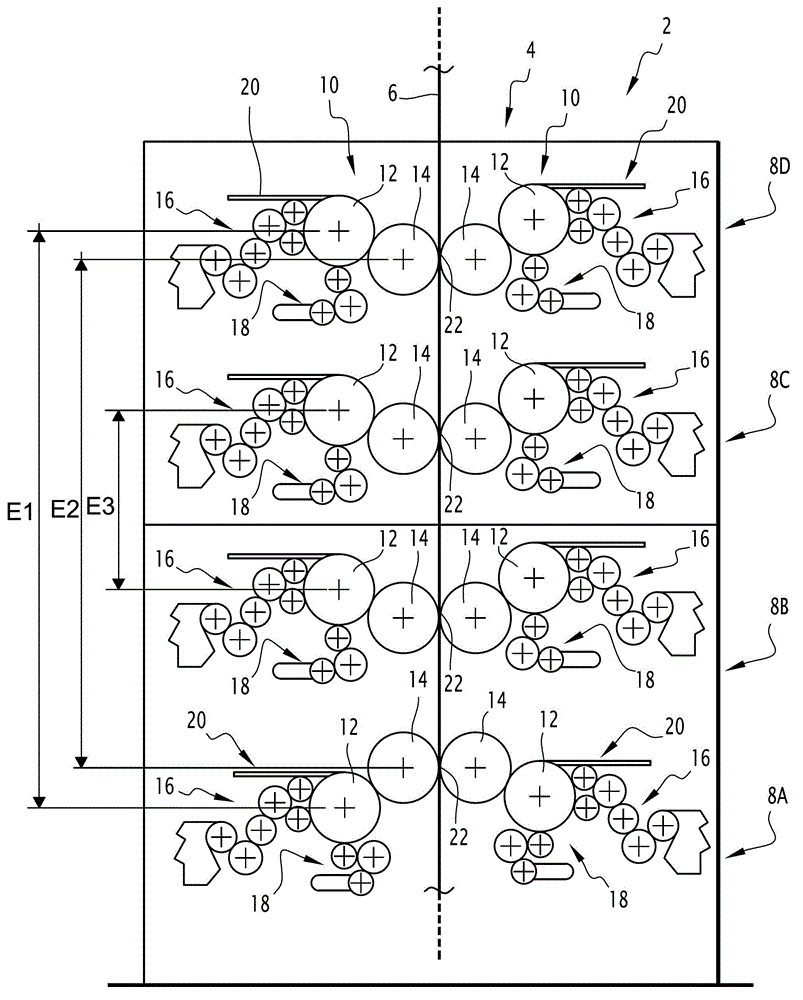

[0017] as in figure 1 As shown in , the offset rotary printing press 2 comprises a printing tower 4 for the offset printing of a continuous web 6 , in particular a paper web.

[0018] Only one printing tower 4 is shown. A rotary printing press 2 typically includes a plurality of printing towers, each capable of printing a web. Downstream of the printing tower, the rotary printing press 2 generally comprises an ensemble of printed web assemblies capable of ensuring longitudinal and / or transverse joining, folding and cutting of the webs, in order to provide booklets or collations on output. Upstream of the printing tower, the rotary printing press 2 generally includes an integrated device for the reeling of the belt.

[0019] The printing tower 4 comprises four vertically stacked printing units 8A, 8B, 8C, 8D. In practice, each printing unit 8A, 8B, 8C, 8D is used to print a color on the belt 6 . Commonly used colors are usually: black, cyan, magenta, and yellow.

[0020] T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap