Rail electric transport cart for winter warming type greenhouse

A winter warm, transport vehicle technology, applied in the direction of transportation of passenger cars, transportation and packaging, railway car body parts, etc., can solve the problems of low efficiency, high labor intensity, slow speed, etc., to improve transportation efficiency, reduce labor intensity, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

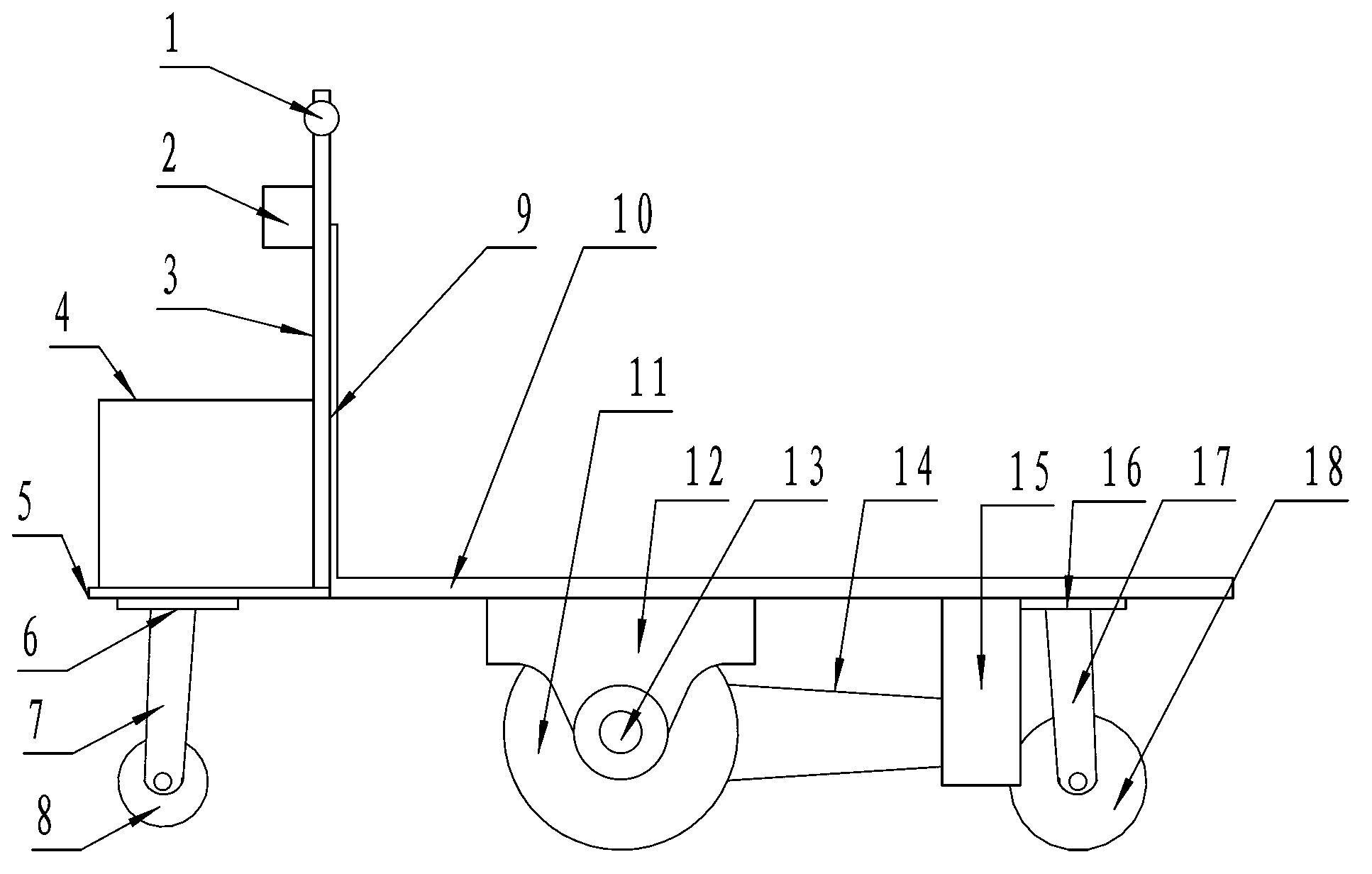

[0017] Embodiment 1, a rail electric transport vehicle for warming type greenhouses, including a vehicle floor 10 and wheels, is characterized in that: the bottom surface of the vehicle floor is equipped with a walking system including driving wheels 11 and guide wheels 18, and the rear end of the vehicle floor is connected to the There is a battery mounting frame 4 and a rear panel 5 and a stand 3 of the control system. The control system includes an operating handle and a power switch installed on the upper part of the stand.

Embodiment 2

[0018] Embodiment 2, a track electric transport vehicle for winter warm type greenhouses, comprising a vehicle floor 10 and wheels, characterized in that: the bottom surface of the vehicle floor is equipped with a walking system including driving wheels 11 and guide wheels 18, and the rear end of the vehicle floor is connected to the There is a battery mounting frame 4 and a rear panel 5 and a stand 3 of the control system. The control system includes an operating handle and a power switch installed on the upper part of the stand.

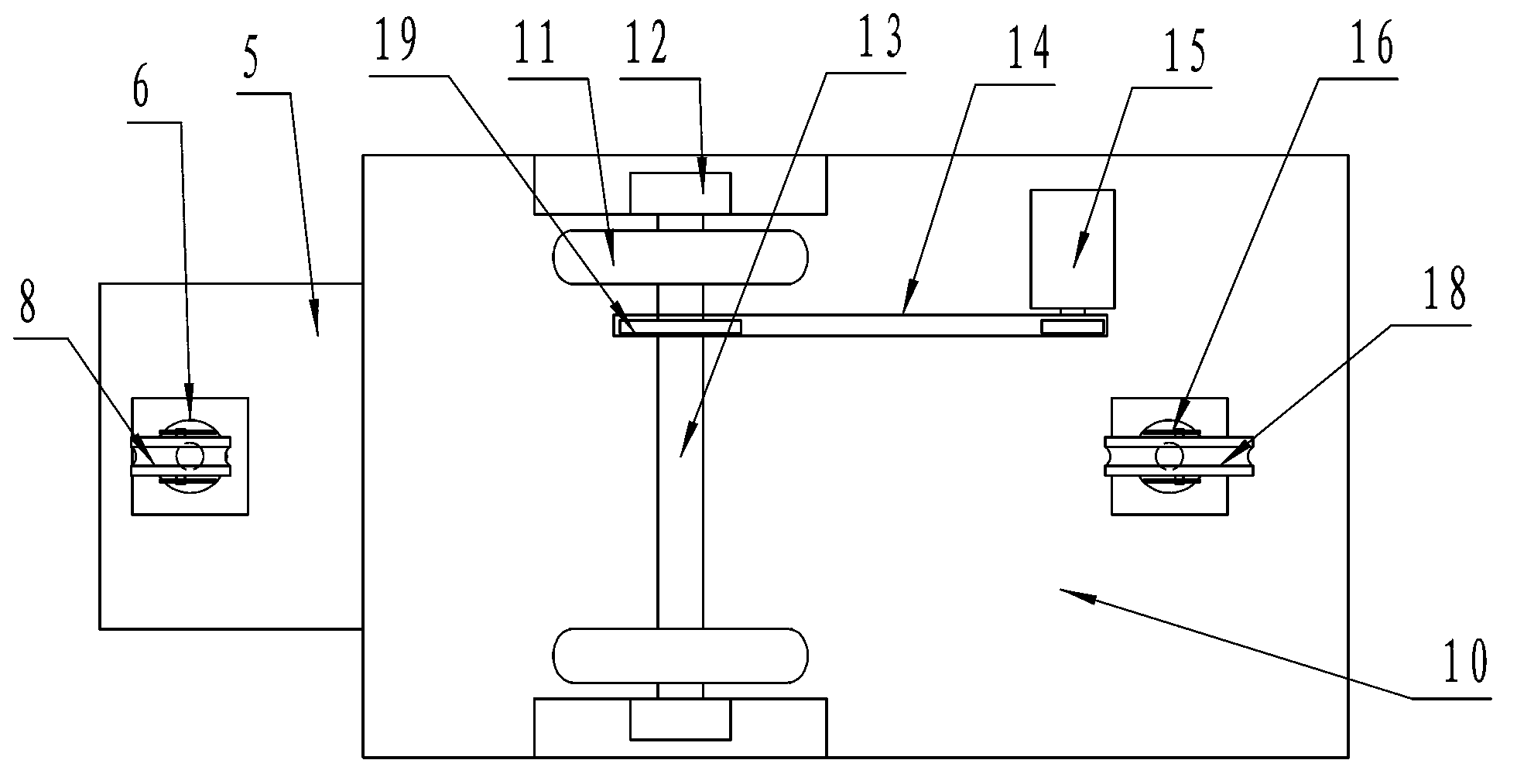

[0019] Described guide wheel is fixed on the front end of vehicle floor center line by the guide wheel bracket 17 that is installed on the guide wheel rotating disk 16, and guide wheel is the sheave wheel that has groove in the middle.

[0020] The driving wheel shaft 13 of described driving wheel is fixed on the bottom surface of the vehicle floor by the driving wheel bearing block 12, and the driving wheel gear 19 installed on the driving wheel s...

Embodiment 3

[0022] Embodiment 3, a track electric transport vehicle for winter warm type greenhouses, comprising a vehicle floor 10 and wheels, characterized in that: the bottom surface of the vehicle floor is equipped with a walking system including driving wheels 11 and guide wheels 18, and the rear end of the vehicle floor is connected to the There is a battery mounting frame 4 and a rear panel 5 and a stand 3 of the control system. The control system includes an operating handle and a power switch installed on the upper part of the stand.

[0023] Described guide wheel is fixed on the front end of vehicle floor midline by the guide wheel support 17 that is installed on the guide wheel rotating disk 16, and guide wheel is the sheave wheel that has groove in the middle.

[0024] The driving wheel shaft 13 in the center of the driving wheel is fixed on the bottom surface of the vehicle floor through the driving wheel bearing seat 12, and the driving wheel gear 19 installed on the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com