Arch-top storage tank with reticulated shell

A vault and reticulated shell technology, applied in containers, packaging, transportation and packaging, etc., can solve problems such as potential safety hazards, achieve the effects of increasing the load-bearing area, ensuring personal safety, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

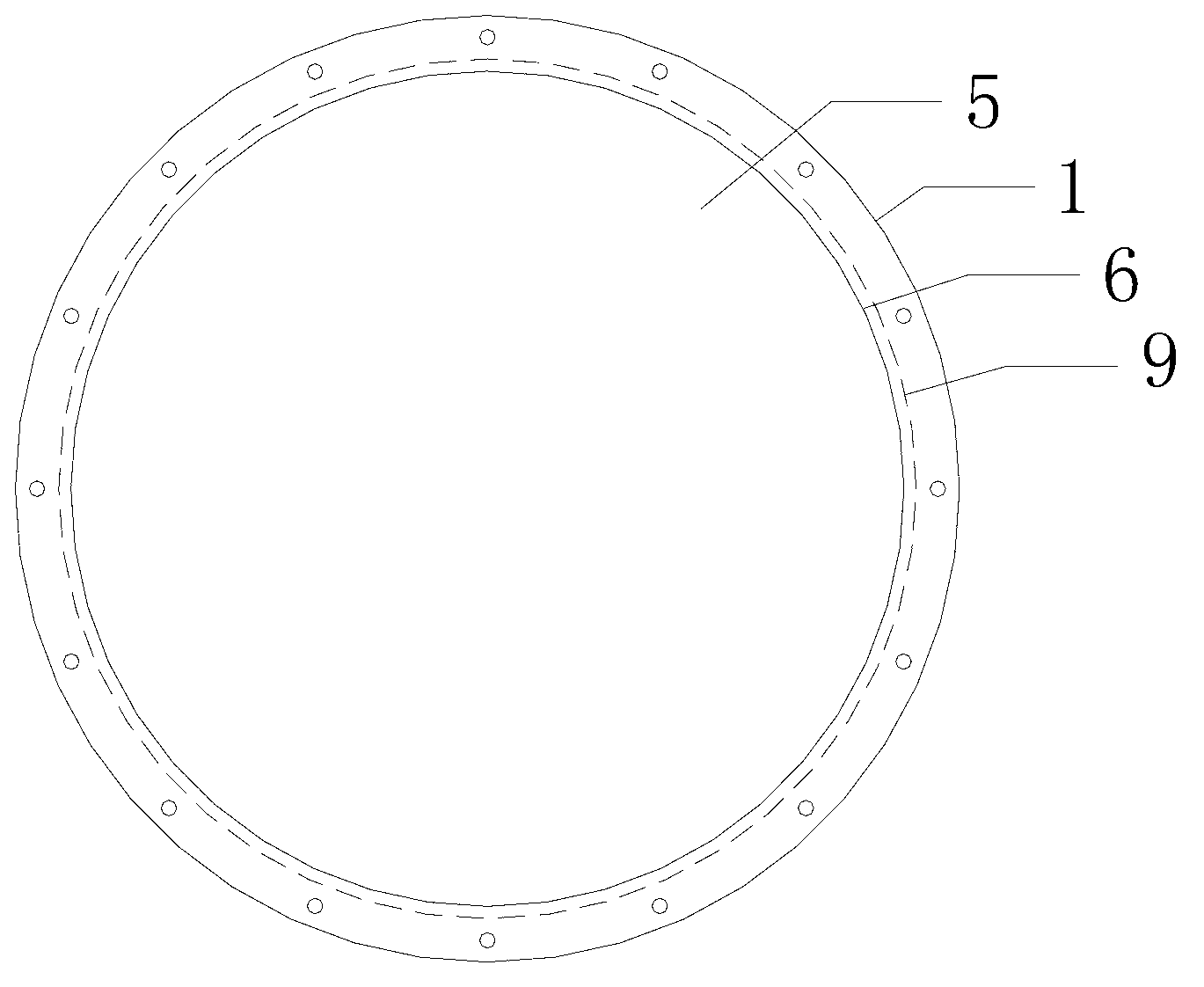

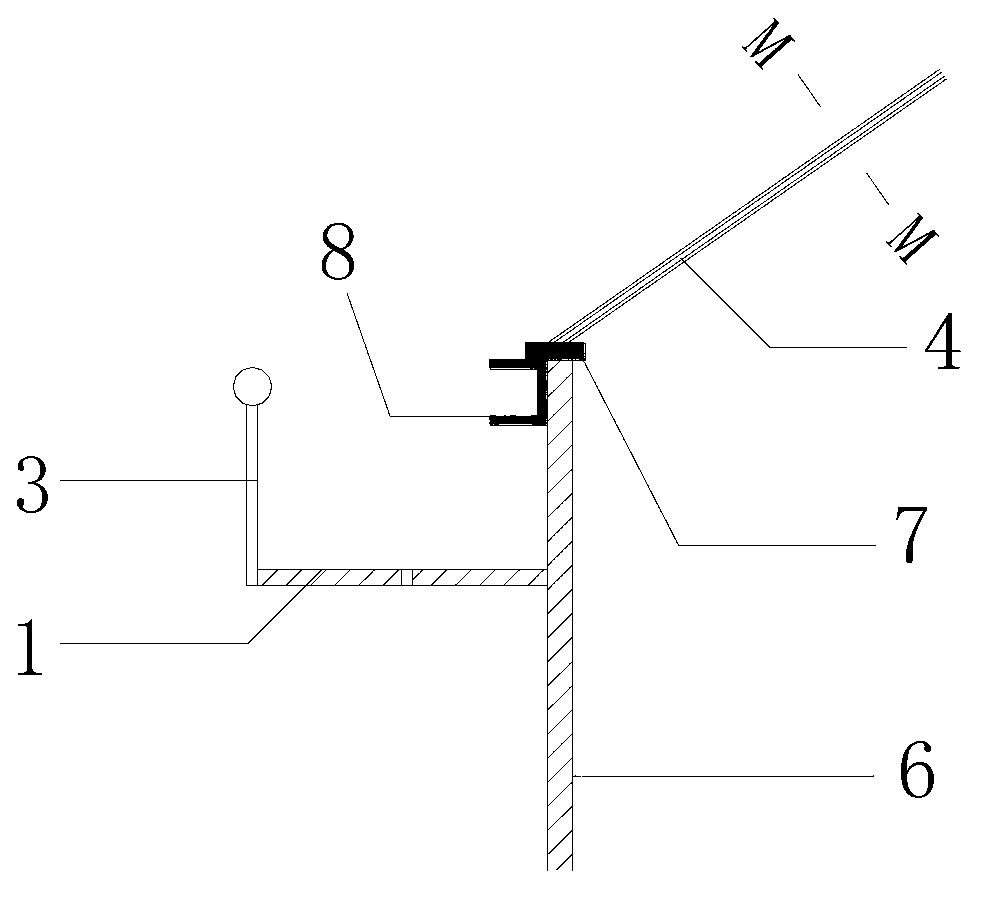

[0035] Such as Figure 4a , Figure 4b , Figure 5a , Figure 5b , Image 6 , Figure 7 As shown, the reticulated shell vault storage tank includes the tank wall 6, the vault 5, the backing plate 7, the reinforcement ring 9, the ring plate 1, the rib plate 2, and the guardrail 3; the ring plate 1 is flush with the top of the tank wall and surrounds the tank The wall 6 is welded with the tank wall 6 for a circle. In order to prevent water accumulation in the ring plate 1, small holes for drainage are distributed on the surface of the ring plate; ribs 2 are evenly arranged at the bottom of the ring plate 1 along the circumferential direction of the tank wall 6, and the ribs The plate 2 is welded with the ring plate 1 and the tank wall 6 to increase the connection strength between the ring plate 2 and the tank wall 6; a backing plate 7 is arranged on the top surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com