Vibration-damping dragging type boosting glass loader capable of rotating easily

A tractor-type, loading and unloading technology, applied in the directions of transportation and packaging, manual conveying devices, conveyor objects, etc., can solve the problems of fragile glass, fragile glass, and the base cannot be rotated, so as to reduce vibration and prevent glass from being broken and damaged. , the effect of mobile convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

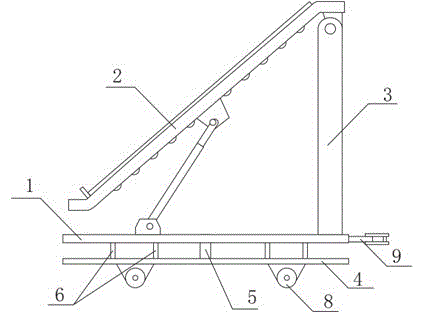

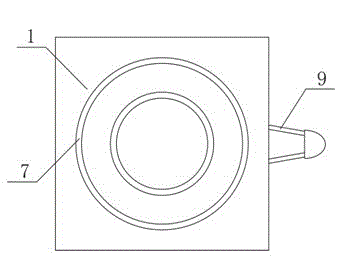

[0015] Embodiment 1: see figure 1 , figure 2 , a shock-absorbing and easy-to-rotate drag-type glass power-assisted loading and unloading vehicle, comprising a square support base plate 1, a glass loading platform 2 above the support base plate 1 and a bracket 3 connecting the two, and a shape and The same load-bearing base plate 4, the middle part of the support base plate 1 and the load-bearing base plate 4 is connected by the rotating shaft 5, the lower surface of the support base plate 1 is provided with an annular chute 7 with the rotating shaft 5 as the center of the circle, and the support base plate 1 and The load-bearing base plate 4 is provided with a relief Shock component 6, one end of the shock-absorbing component 6 is fixed on the load-bearing base plate 4, and the other end extends into the annular chute 7 and is slidably connected with the annular chute 7. There is at least one annular chute 7, and each annular chute The groove 7 has at least two shock-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com