Multi-union high-speed paper conveying gathering mechanism with large inclination angle and large turning radius

A technology of paper feeding mechanism and large turning, which is applied in the direction of transportation and packaging, sending objects, and thin material processing, etc. It can solve problems such as wrinkles, collision deformation, and limited movement speed, so as to achieve fast conveying speed, increase friction, and manufacture low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

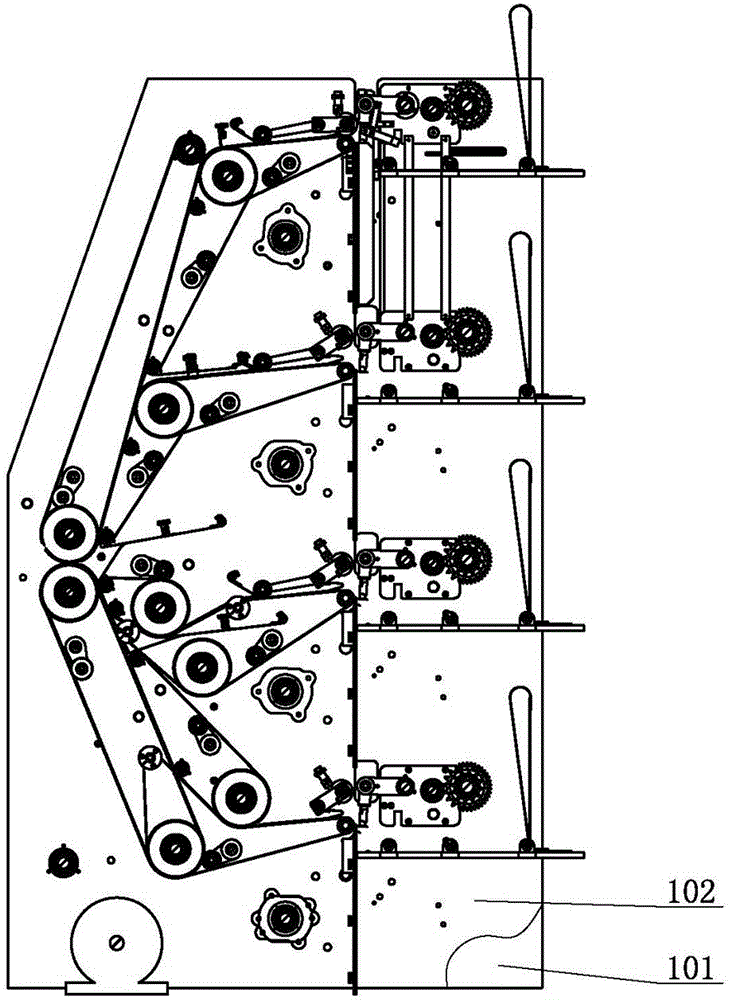

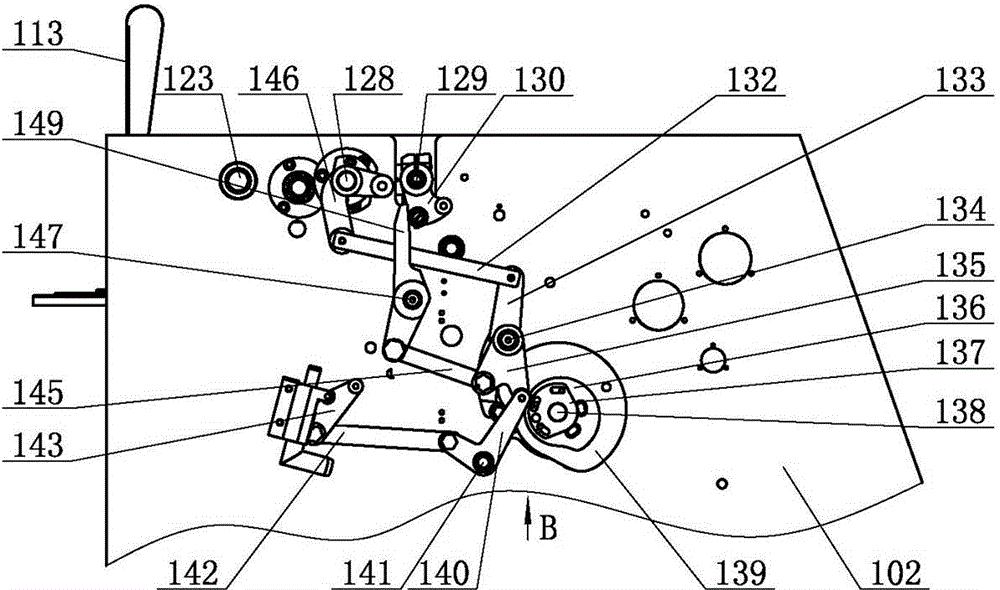

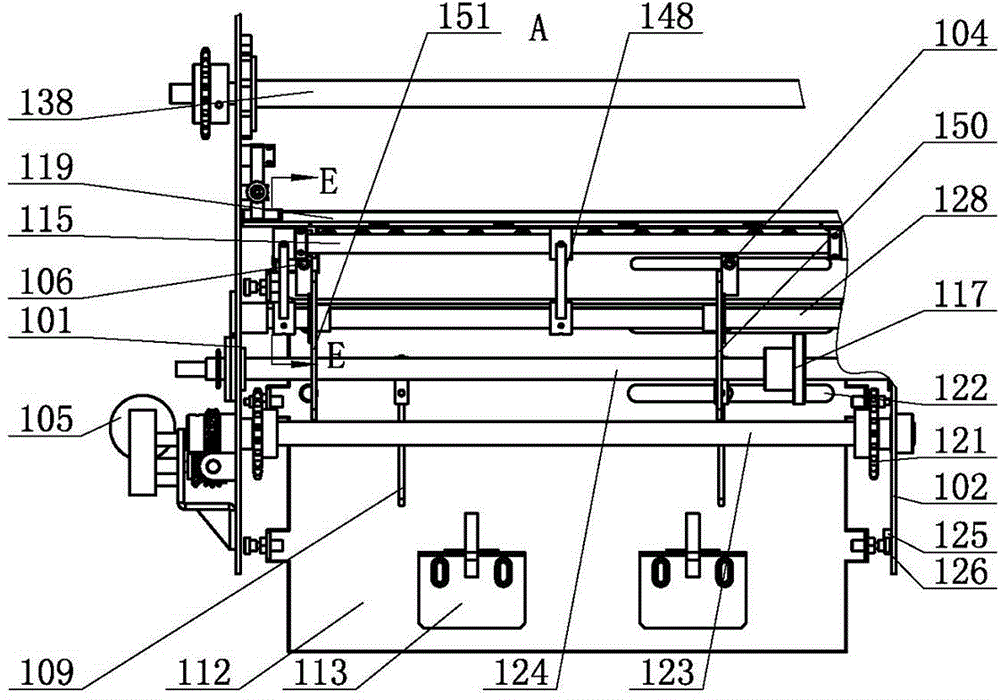

[0010] The multi-connected high-speed paper conveying and collecting mechanism with large inclination angle and large turning radius according to the present invention, such as figure 1As shown, it includes a feeding mechanism 1 and a feeding mechanism 2. The paper feeding mechanism 1 includes a first side plate 101 and a second side plate 102 . At least two paper feeding units are installed vertically between the first side plate 101 and the second side plate 102 . The number of paper feeding units can be designed as three, four, five or more as required. All paper feeding units act synchronously, and can respectively feed multiple single sheets into the paper feeding mechanism 2 at the same time. The paper feeding mechanism 2 is installed in the first side plate 101 and the second side plate 102 .

[0011] like Figure 10 As shown, the paper feeding mechanism 2 includes three rows of conveyor belts. The first row has a vertical second transmission belt 212 , the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com