Hydraulic controls and presses having such controls

A control device and technology for presses, applied in the field of presses, can solve problems such as unfavorable energy, and achieve the effects of improving efficiency, adjusting dynamic performance, and reducing cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

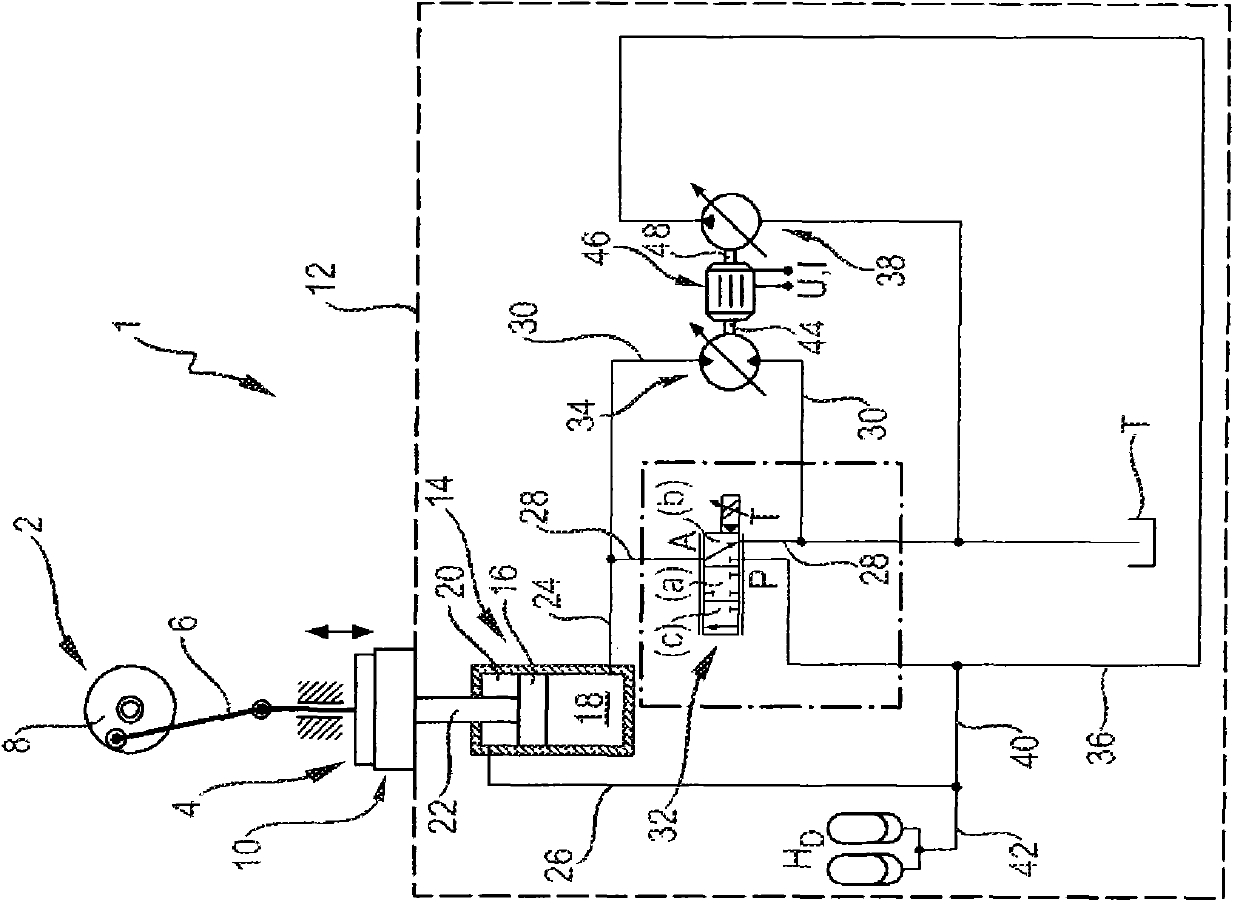

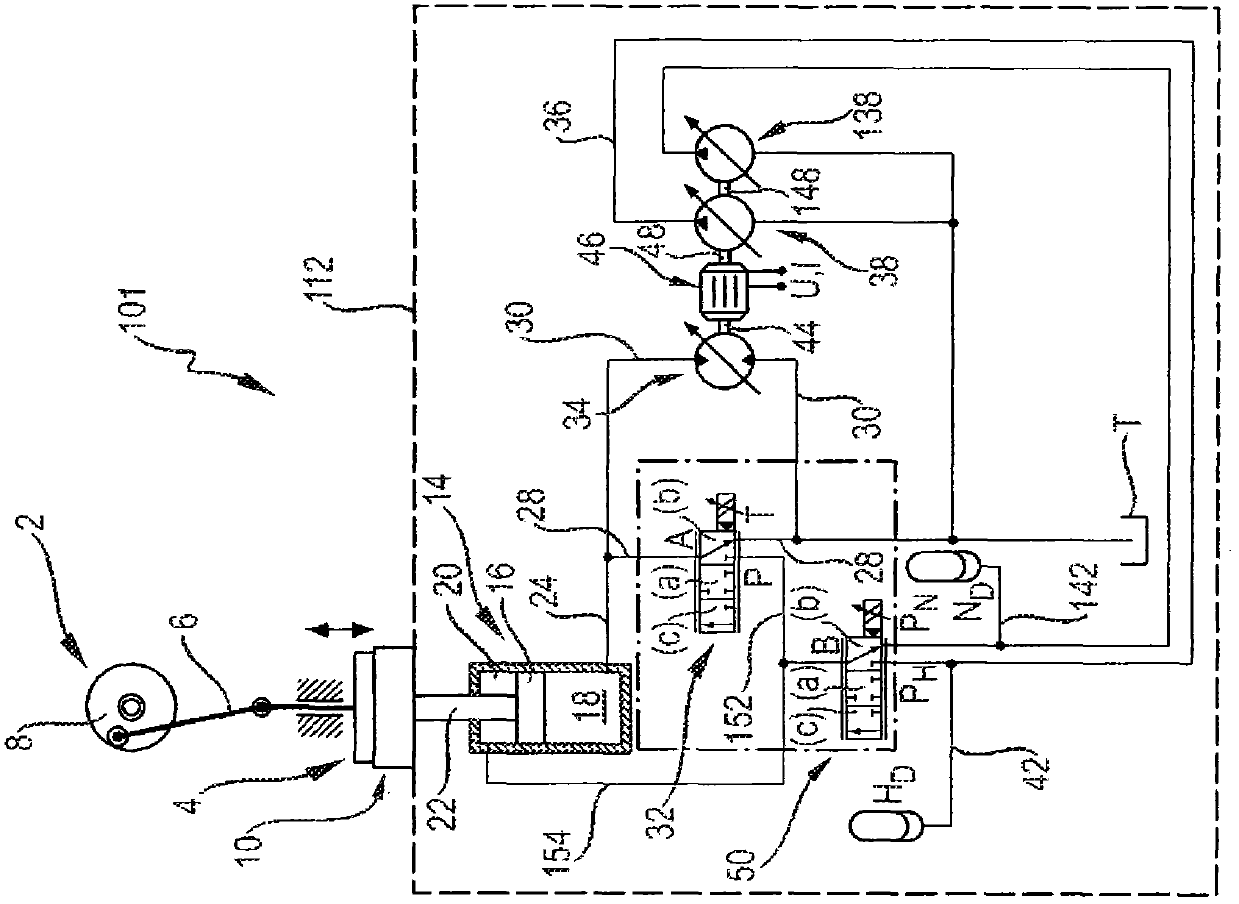

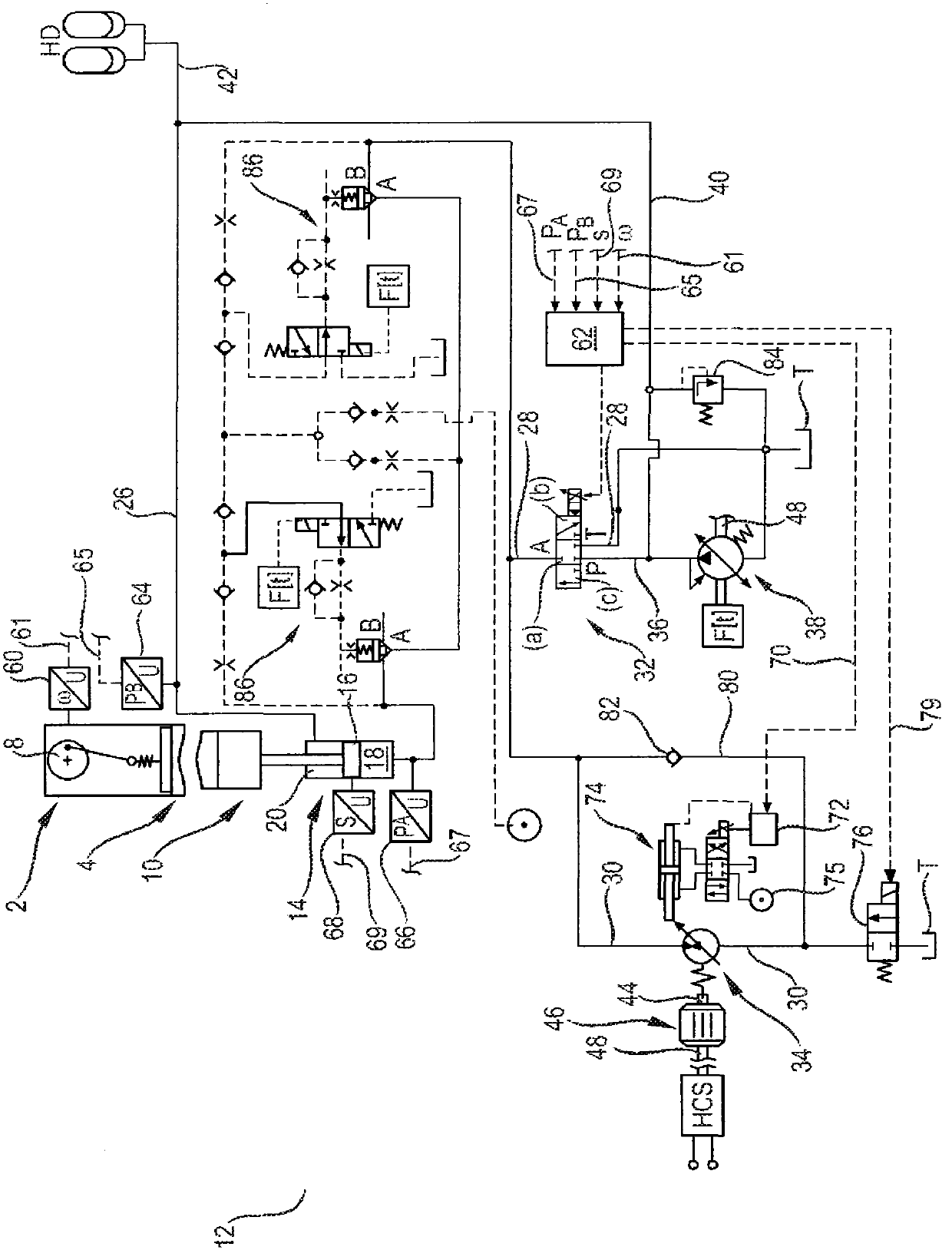

[0044] The press 1 shown in FIG. 1 has an upper die 4 driven by an eccentric drive mechanism 2 . It is connected to the drive mechanism 2 via the connecting rod 6. Press 1 is designed as a deep drawing machine. To apply force to the workpiece, the press 1 has a die holder 10 or a deep-drawing pad. During the stamping process, the machining force is applied to the workpiece by the upper die 4 via the counter-fixation of the deep-drawing pad 10 . In order to be able to adjust the force, the opposing fixing force of the die base 10 in the upper die 4 can be adjusted through the hydraulic control device 12 . The control device has a working cylinder 14 with a piston 16 , which delimits a working chamber or a pressure medium chamber 18 that acts against the punch 4 . The die holder 10 and thus the workpiece arranged between the die holder and the upper die 4 is supported on the piston 16 . The working cylinder 14 is designed as a double-acting differential cylinder and has a fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com