Device of ultralow frequency test in horizontal direction

A modal test, horizontal direction technology, applied in the direction of measuring device, machine/structural component test, vibration test, etc., can solve problems that cannot be eliminated, and achieve the effect of no tracheal disturbance, valid test data, and continuous air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

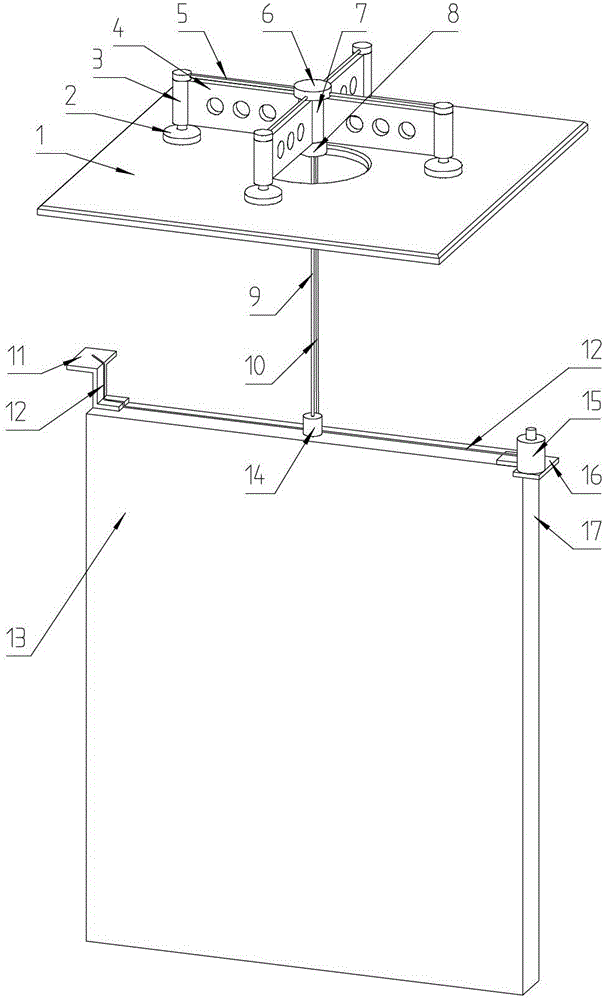

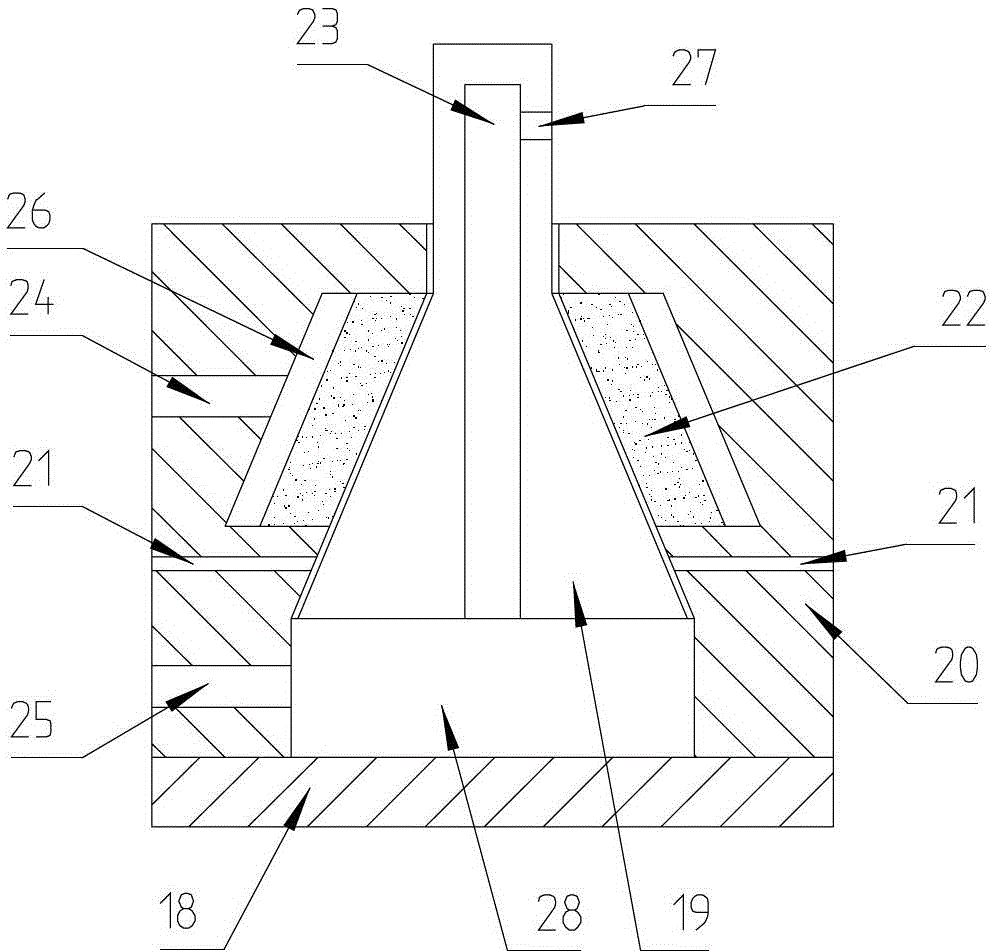

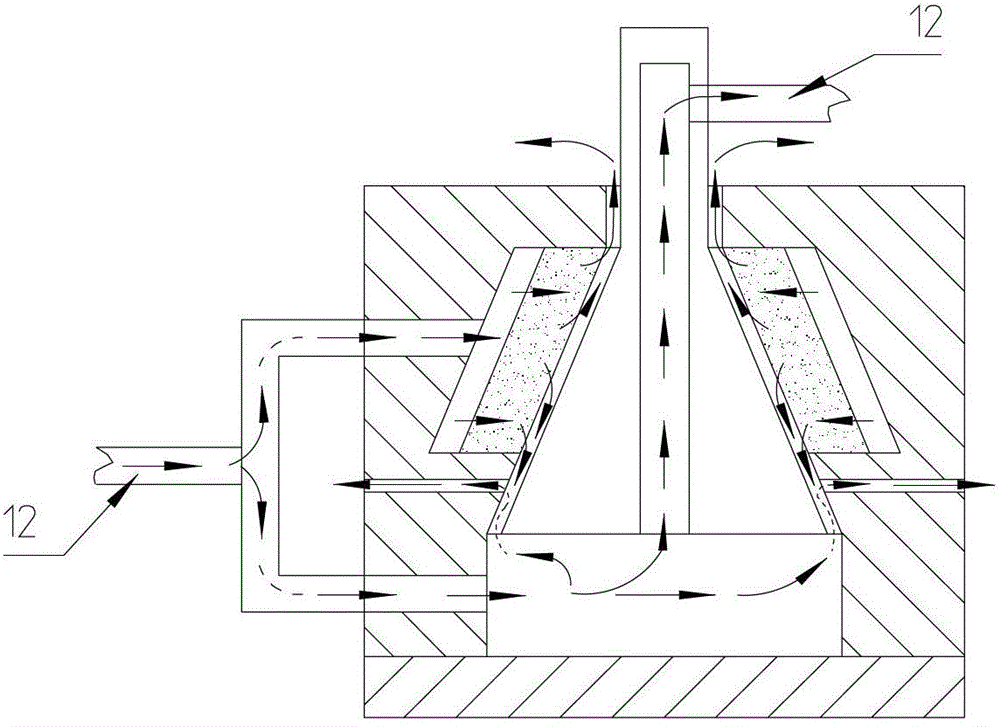

[0014] refer to Figure 1 ~ Figure 3 , an ultra-low frequency modal test device in the horizontal direction, comprising an air flotation plate 1, an air flotation pad 2, an air flotation frame 4, an end cover 6, a bottom cover 8, a fixed end 14 of a pull rope, a pull rope 9, and an air pipe 10 And 12. The frictionless rotating air supply device 15 , wherein the frictionless rotating air supply device 15 includes an air bearing shaft 19 , an air bearing sleeve 20 and a base 18 . The air float frame 4 is cross-shaped, the air float pad 2 is installed on the four corners of the air float frame 4, the air float pad 2 is placed on the air float plate 1, the center of the air float frame 4 and There are air storage chambers 7 and 3 at the four corners, and the end cover 6 is installed on the upper end of the air storage chamber 7 in the center of the air flotation frame. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com