Device for fixing prefabricated beam bridge face water drain pipe

A fixing device and drainage pipe technology, which is applied to mold fixtures, manufacturing tools, ceramic molding machines, etc., can solve the problems of affecting the accuracy of the installation position of the drainage pipe, difficulty in discharging water in the bridge area, affecting the appearance quality of the beam body, etc. The effect of saving labor costs, lowering the center of gravity, and saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

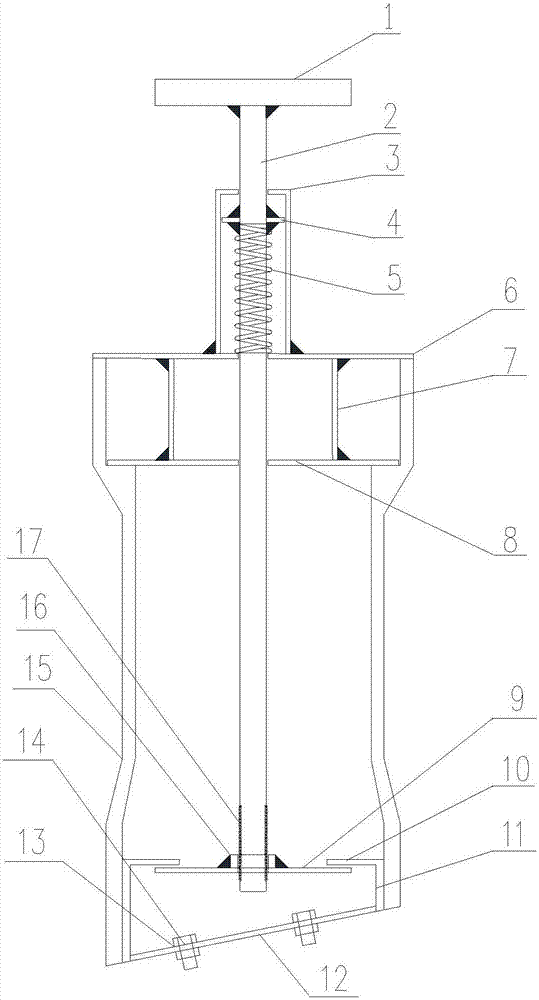

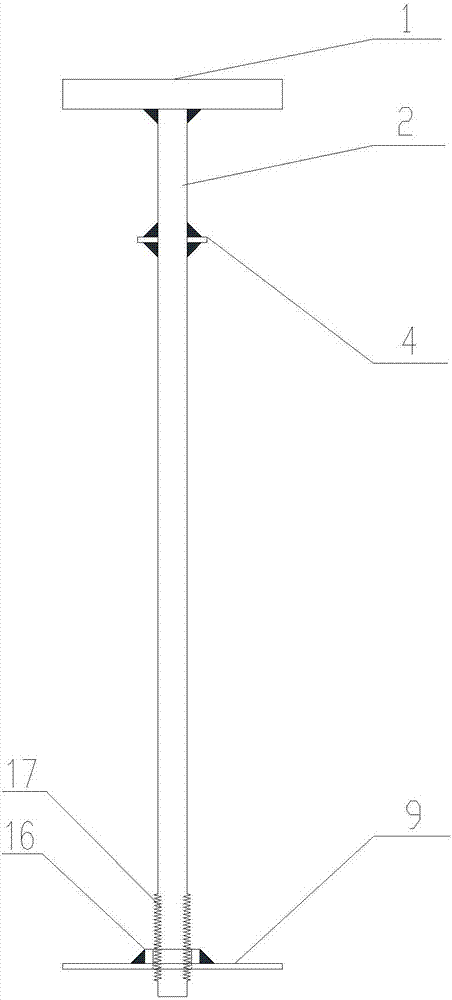

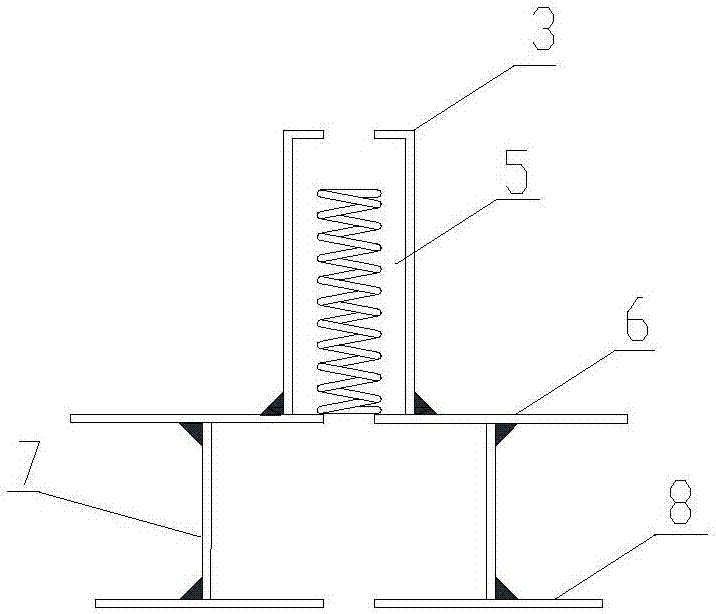

[0018] Referring to the accompanying drawings, the present invention includes a handle device. The handle device is to install a handle 1 on the upper end of the connecting rod 2. The key technology is to install a clamping steel plate 9 at the lower end of the handle device. Steel plate 4; the handle device is also connected to the upper fixing device and the bottom fixing device, the upper fixing device is to cover the protective tube 3 on the connection rod 2, the first circular steel plate 4 is located in the protective tube 3, and the lower end of the protective tube 3 is fixed to the second round Steel plate 6, the second round steel plate 6 fixes the third round steel plate 8 by connecting the steel plate 7, and the spring 5 is placed between the first round steel plate 4 and the second round steel plate 6 in the protective tube 3; the bottom fixing device is Two crescent-shaped steel plates 10 are arranged on the upper opening of the wedge-shaped steel ring 11, and a bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com