Large decorative strip second fulcrum connection system and its installation method

A connection system and decorative strip technology, which is applied in the field of the second fulcrum connection system of large decorative strips, can solve the problems of large lateral force, high requirements for steel parts positioning, high installation accuracy requirements, etc., and achieve the purpose of increasing the absorption of structural deviations Ability, control of installation quality, and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below with reference to the accompanying drawings.

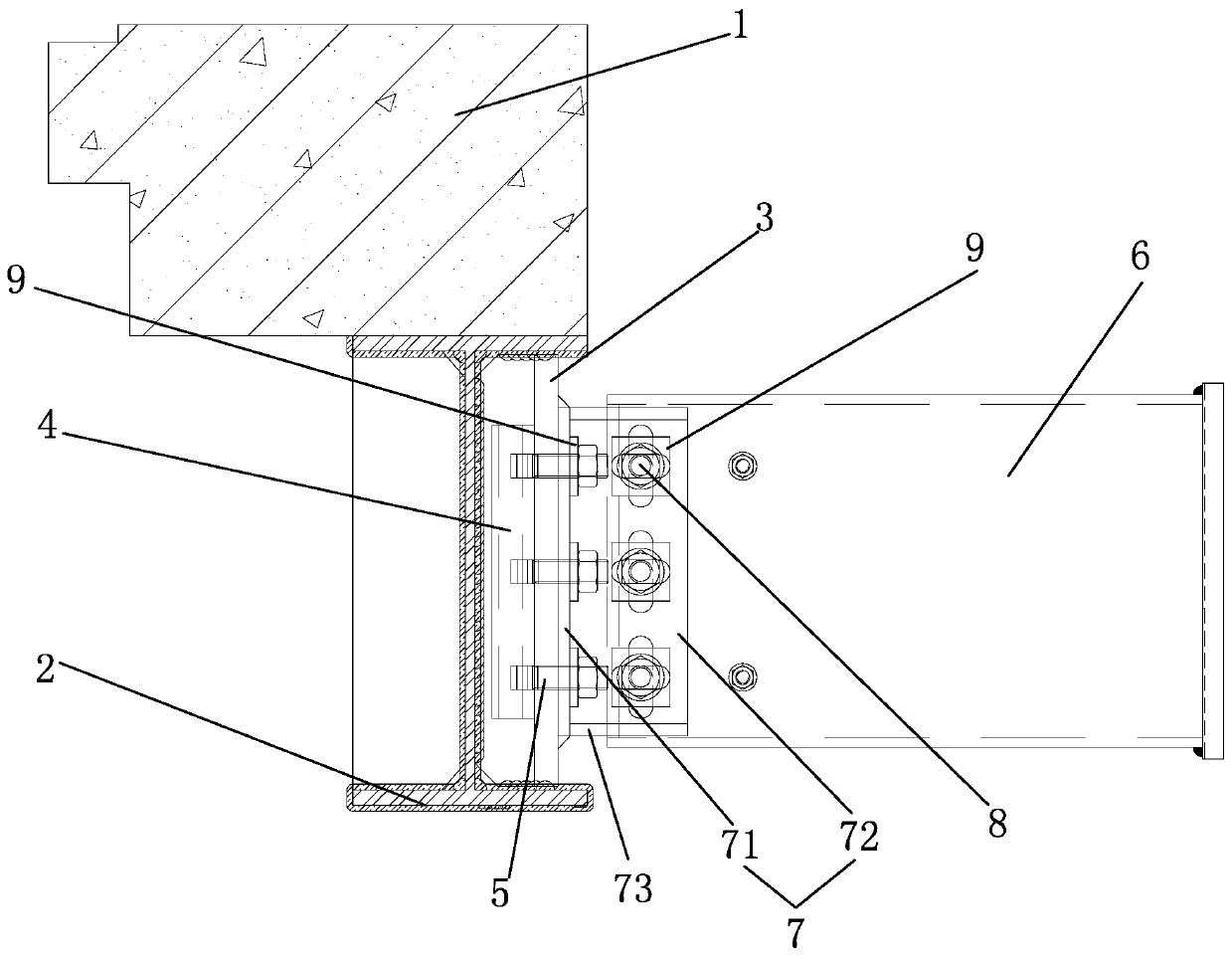

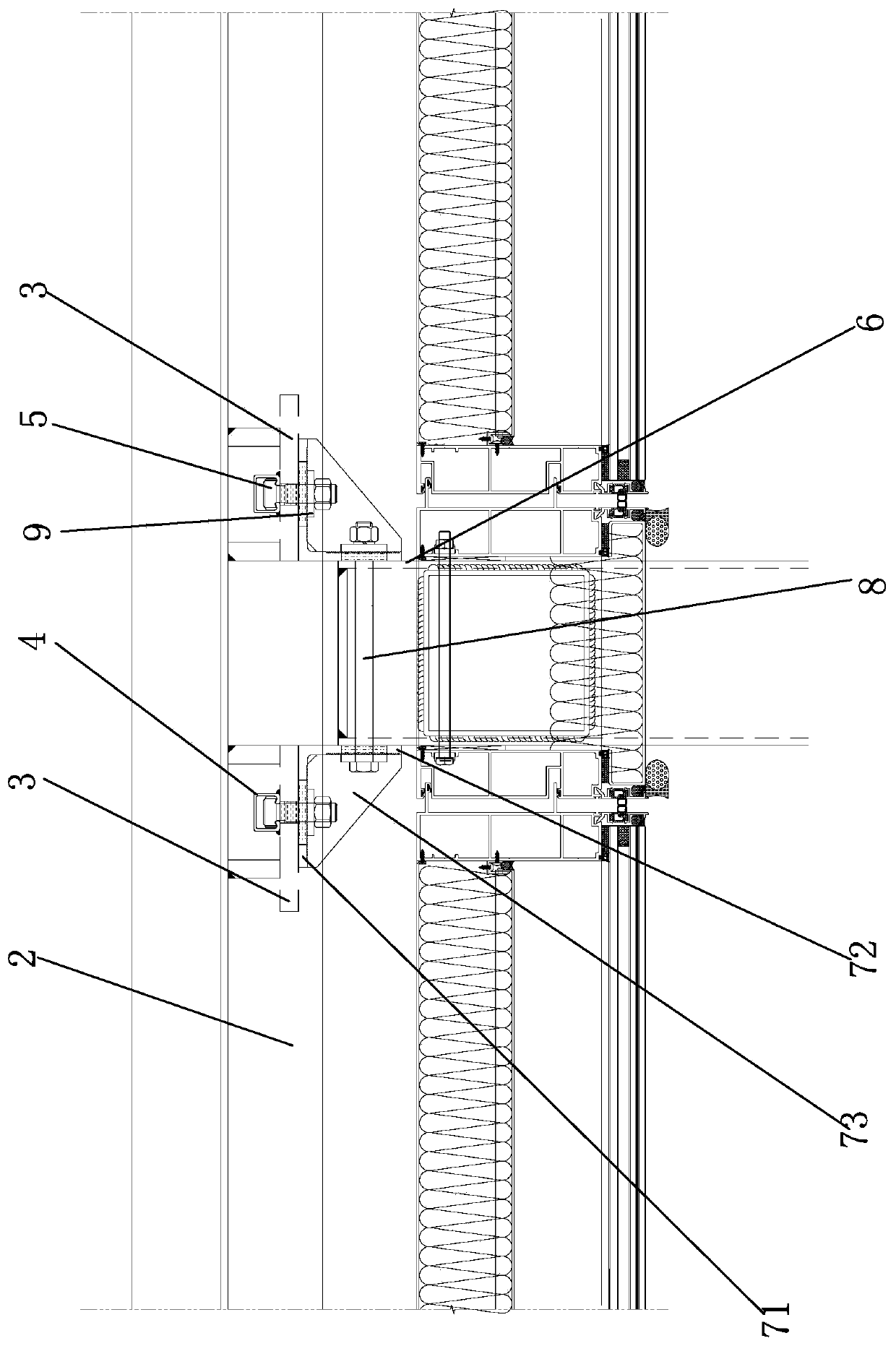

[0019] Such as figure 1 , figure 2 As shown, the present invention provides a second fulcrum connection system for large decorative strips, which includes a structural steel beam 2 fixed on the main structure 1, and a flat plate 3 is welded and fixed on the outer surface of the structural steel beam 2, and the flat plate 3 is provided with a vertical To the through groove, the side of the through groove facing the structural steel beam 2 is welded with a Hafen groove 4, and the opening of the Hafen groove 4 is aligned with the through groove. A slidable T-bolt 5 is provided in the Hafen slot 4 . The outer surface of the flat panel 3 is provided with a horizontal connecting beam 6 , and the side of the connecting beam 6 is fixedly connected to the flat panel 3 through an L-shaped adapter 7 . The adapter 7 has a first side 71 and a second side 72 perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com