A constant force output air flotation device with electromagnetic compensation

A technology of constant force output and output cylinder, applied in the direction of fluid pressure actuating device, etc., can solve the problems of inaccurate sensor measurement, difficulty in maintaining constant output force value, low constant force output accuracy, etc., and achieve high-precision constant force output. , the formation of gas film is stable, the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

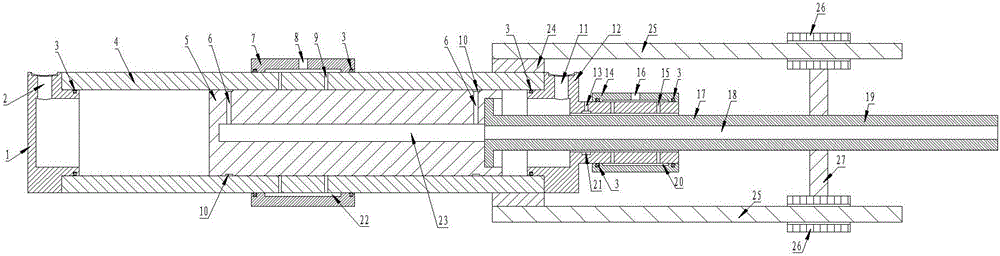

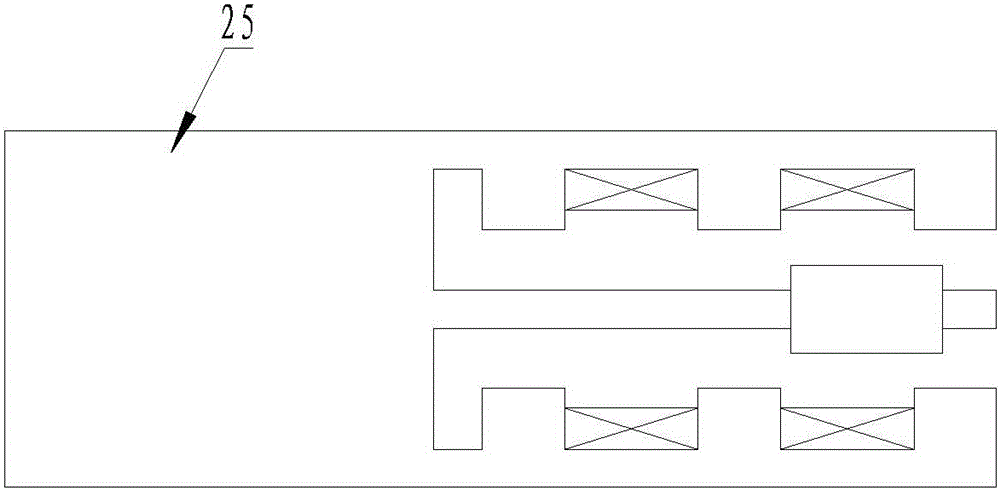

[0026] combine Figure 1~2 , a constant force output air flotation device with electromagnetic compensation, comprising an output cylinder and a magnetic device; the output cylinder includes a piston 5, a piston rod 17, a cylinder barrel 4, an end cover 1, a cylinder barrel cover 12, and an air intake sleeve; The magnetic device includes a long-stroke moving coil 26 and an exciter iron core 25 .

[0027] The piston 5 is set in the cylinder 4 and there is a very small gap between it and the cylinder wall. The two ends of the cylinder 4 are respectively set with the end cover 1 and the cylinder cover 12. The piston rod 17 is connected to the piston 5, and the piston rod 17 passes through the cylinder. There is a very small gap between the cover 12 and the inner wall of the cylinder cover; the end cover 1 is provided with an air inlet 2, and the cylinder cover 12 is provided with an air outlet 11; the air inlet 2 is connected to the differential pressure sensor and the large stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com