A Constant Force Output Device Unaffected by Tracheal Disturbance

A constant force output, trachea technology, applied in the direction of fluid pressure actuation device, can solve the problems of inaccurate sensor measurement, difficult to control small constant force, difficult to keep the output force value constant, etc., to achieve small constant force output, gas Stable film formation and good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

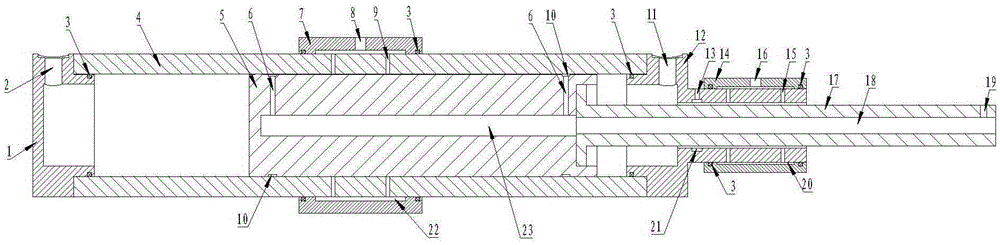

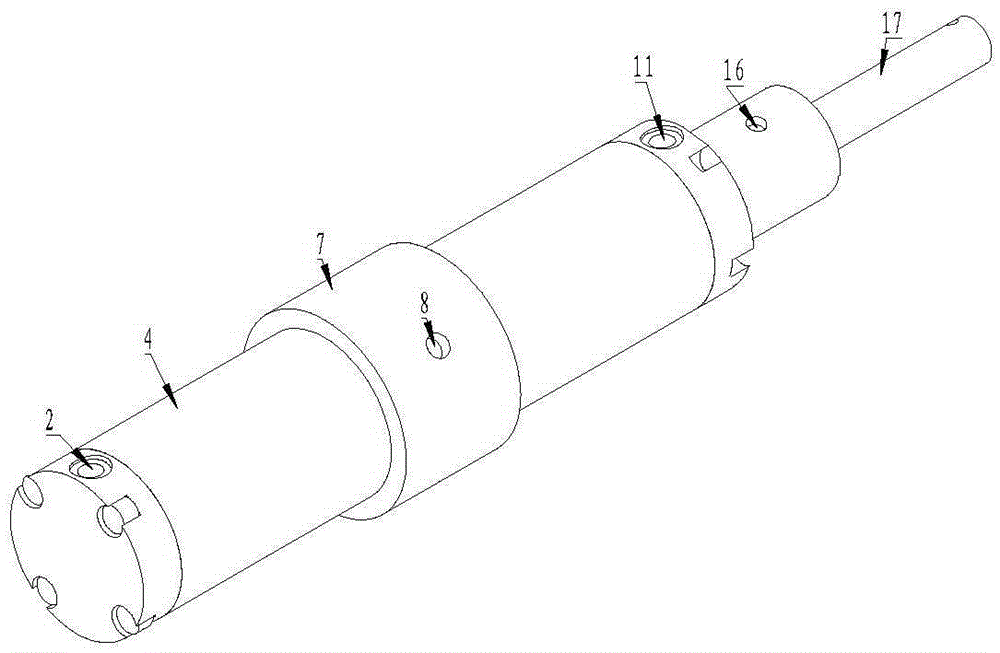

[0025] A constant force output device not affected by trachea disturbance, comprising a piston 5, a piston rod 17, a cylinder 4, an end cover 1, a cylinder cover 12, and an air intake sleeve;

[0026] The piston 5 is set in the cylinder 4 and there is a very small gap between it and the cylinder wall. The two ends of the cylinder 4 are respectively set with the end cover 1 and the cylinder cover 12. The piston rod 17 is connected to the piston 5, and the piston rod 17 passes through the cylinder. There is a very small gap between the cover 12 and the inner wall of the cylinder cover; the end cover 1 is provided with an air inlet 2, and the cylinder cover 12 is provided with an air outlet 11; the air inlet 2 is connected to the air pressure sensor and the large gas storage through the air pipe Tanks, large gas storage tanks store constant pressure gas.

[0027] The air intake sleeve includes a first air intake sleeve 7 and a second air intake sleeve 14, the first air intake sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com