Biological rotating disc in combination of non-woven fabrics package and biological carrier filler filling

A biological carrier and biological turntable technology, applied in the fields of environmental protection and water treatment equipment, can solve the problems of low biomass, low treatment efficiency, small specific surface area, etc. well-mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

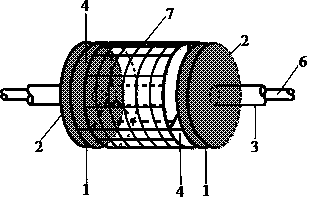

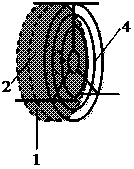

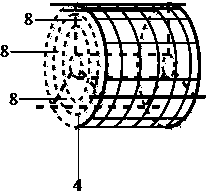

[0019] see Figure 1-Figure 4 , the bio-rotary disc of the present invention is a combination of non-woven fabric wrapping and biological carrier filler filling, including several biological bio-discs 1 and rotating shafts 6 . All bio-discs 1 are arranged in parallel, and a cylinder net 7 is arranged between two adjacent bio-discs 1, that is, there is one more bio-disc than the cylinder net, and the diameter of the cylinder net 7 matches the diameter of the bio-disc 1 , both ends of the cylindrical net 7 are fixed on the corresponding bio-disc 1 . A rotating shaft sleeve 3 passes through the center of all the bio-discs 1 and the cylindrical net 7, the rotating shaft sleeve 3 is set on the rotating shaft 6, and the rotating shaft 6 is driven to rotate by the driving device, and the rotating shaft sleeve 3 and the rotating shaft 6 are fixed with screws Can ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com