A kind of sewage treatment equipment based on mbbr process

A sewage treatment equipment and process technology, applied in water/sewage treatment equipment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of easy accumulation of carriers in protective covers, reduce the amount of biofilm formation, etc. The effect of film volume, not easy to be damaged and accumulated, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

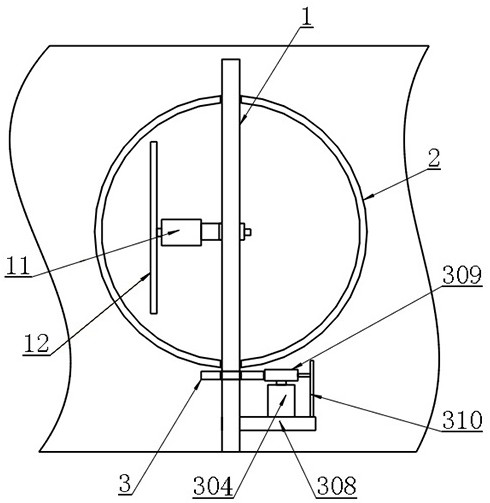

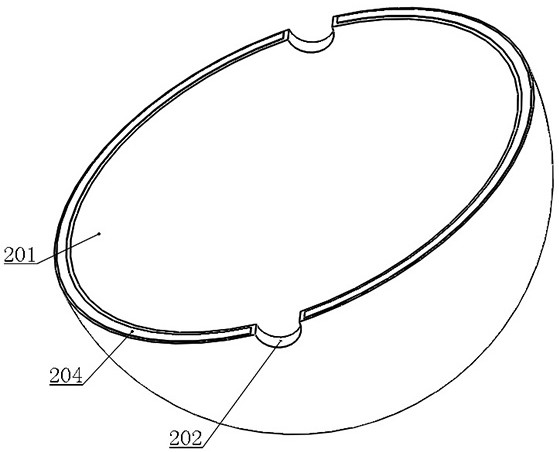

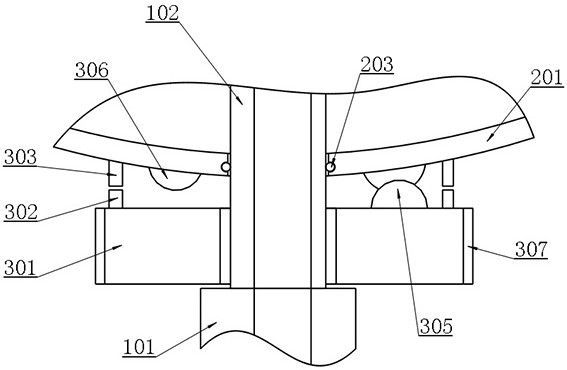

[0022] Example: as attached figure 1 , 2 , 3 and attached Figure 4 Shown, a kind of sewage treatment equipment based on MBBR technology, comprises stirring motor 11, and the stirring fan blade 12 that is arranged on described stirring motor 11, also includes the installation column unit 1 that is arranged on the bottom surface of the pool body, socket set On the installation column unit 1 and used to cover and protect the spherical cover unit 2 of the stirring fan blade 12, and sleeved on the installation column unit 1 and located at the position below the spherical cover unit 2 and The rotary drive unit 3 used to remove the accumulated carrier filler on the outer surface of the spherical cover unit 2 by rotating and jacking up the spherical cover unit 2 .

[0023] In this embodiment, the stirring motor 11 is connected to an exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com