Combined biological turntable reactor for implementing one-step autotrophic nitrogen removal process

A technology of autotrophic denitrification and biological turntable, which is applied in the direction of aerobic process treatment, sustainable biological treatment, aerobic and anaerobic process treatment, etc. AAOB slow growth and other issues, to save operating costs and energy consumption, easy to achieve and control, enhance the performance of nitrogen removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

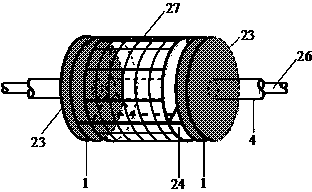

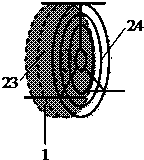

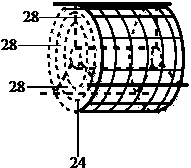

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] see Figure 1-Figure 5 , the present invention realizes the combined type biological turntable reactor of single-stage autotrophic denitrification process, comprises the closed reaction vessel 2 that is used for sewage treatment, and reaction vessel 2 is installed on the stainless steel frame 16, and reaction vessel 2 is connected with inlet through water inlet pipe. The water tank 20 is connected, and a peristaltic pump 21 is arranged on the water inlet pipe to periodically pump the sewage in the water inlet tank into the reaction container. The reaction vessel is provided with a number of biological discs 1, an aeration device and an internal heating device 11 used for the biological reaction. A water outlet 9 is provided on the side wall of the reaction vessel 2 for controlling the amount of sewage in the reaction vessel.

[0028] All biological d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com