High-steel-grade anti-sulfur drill pipe material and preparation method thereof

A steel grade and drill pipe technology, which is applied in the field of high steel grade sulfur-resistant drill pipe materials and its preparation, can solve the problems of hydrogen sulfide stress corrosion cracking susceptibility, well drop, drill tool breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

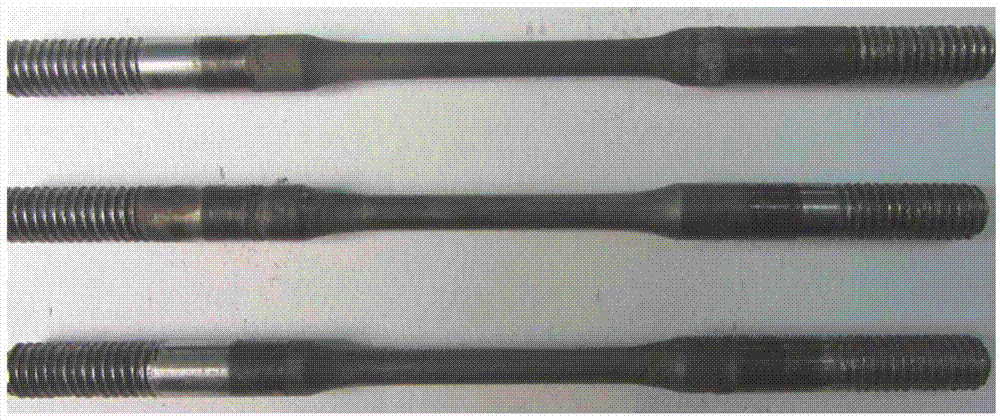

[0024] Embodiments 1-3 respectively provide a high-grade steel-grade sulfur-resistant drill pipe material, and its preparation method comprises the following steps:

[0025] Select raw materials according to the composition of the high-steel-grade sulfur-resistant drill pipe material, wherein the composition of the high-steel-grade sulfur-resistant drill pipe material of Embodiment 1-3 is as shown in Table 1;

[0026] Add alloying elements in pure molten iron as raw materials, smelt the raw materials through a converter, and then cast them into ingots after vacuum degassing, refining outside the furnace and electroslag remelting purification treatment, wherein, the obtained in Examples 1-3 The outer diameter of the ingot is shown in Table 2;

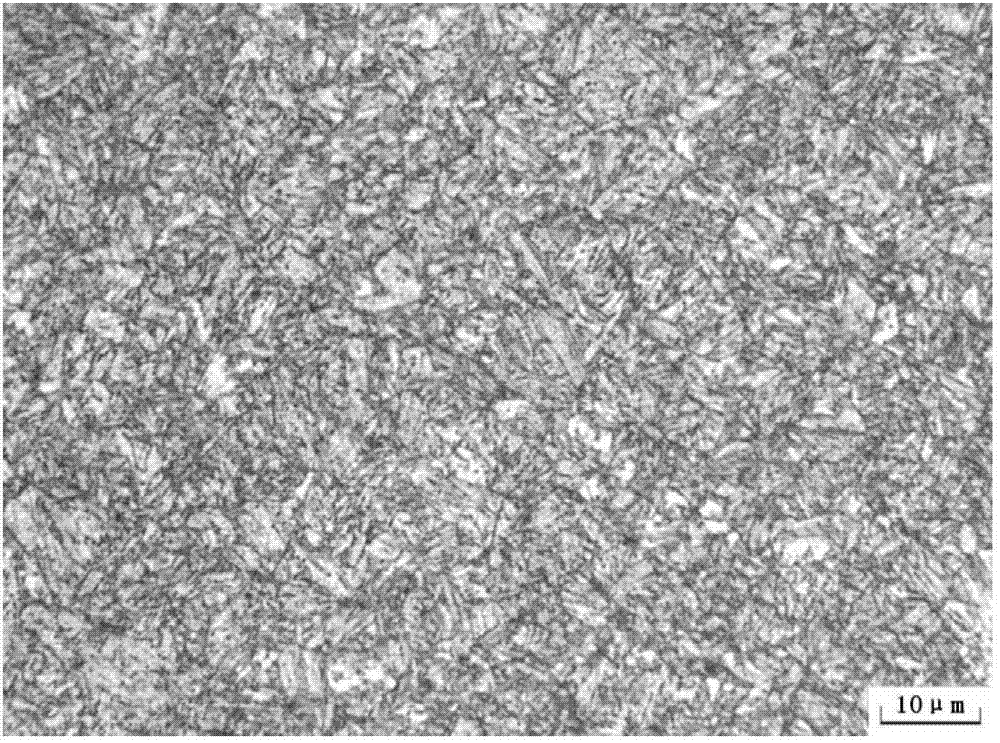

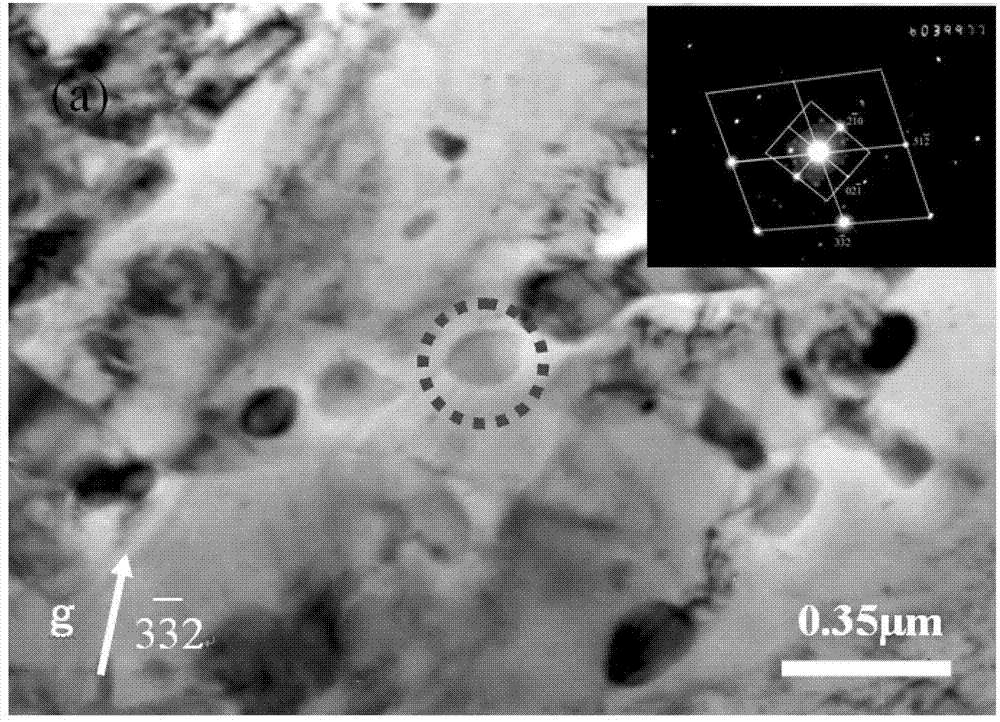

[0027] Then the ingot is kept at a certain temperature for a certain period of time to obtain a material with a fully austenitic structure, and then the material with a fully austenitic structure is sequentially pierced and rolled at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com