Artistic window frame section bar, sliding window and casement window

A technology of artistic modeling and profiles, applied to windows/doors, leaf frames, building structures, etc., can solve the problems of increased production costs, high labor intensity, waste of materials and capital consumption, etc., to achieve saving and reduction in production process Production cost and the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

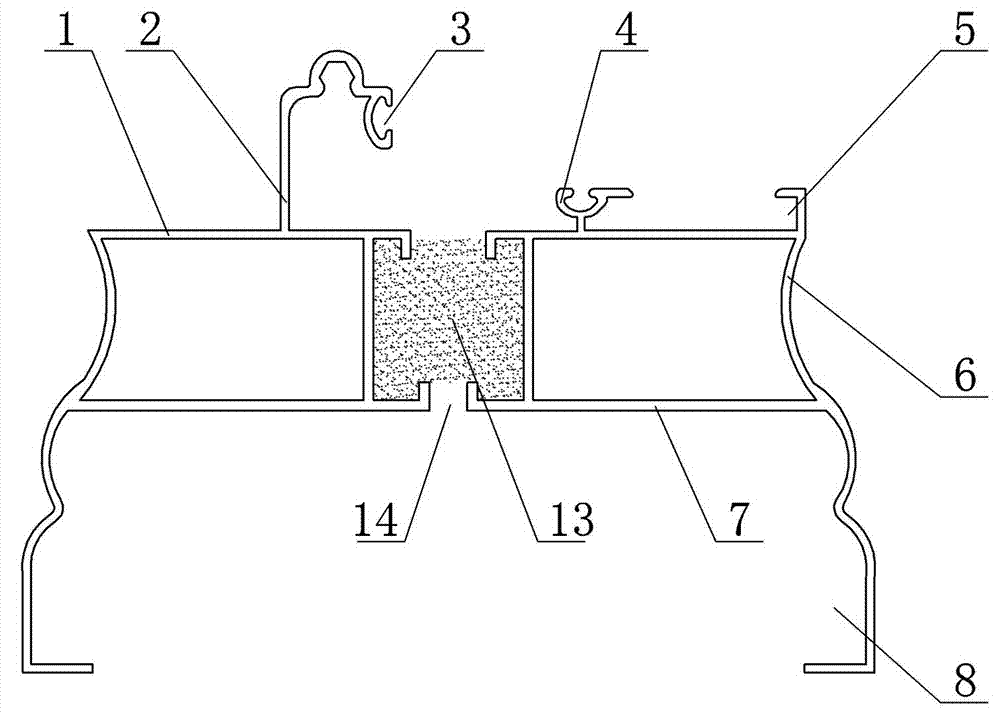

[0038] Embodiment one: see figure 1 , an art-shaped window frame profile, including a hollow cylindrical body formed by the combination of convex and concave arc surfaces. The hollow cylindrical body is composed of a top surface 1, a bottom surface 7 and two side surfaces 6. Parallel, the width of the bottom surface 7 is greater than the width of the top surface 1, one side of the outer surface of the top surface 1 is provided with a guide rail 2, and one side of the guide rail 2 is provided with a C-shaped card slot 3 for clamping the seal. The bottom of the side surface 6 is provided with a lower fixing groove 8, and the other side of the top surface of the hollow prismatic body is provided with a clamping groove 5, and a locking groove 5 is provided between the guide rail 2 on the outer surface of the top surface 1 and the clamping groove 5. track 4.

[0039] The side surfaces 6 of the hollow cylindrical body are formed by the combination of convex and concave arc surfaces...

Embodiment 2

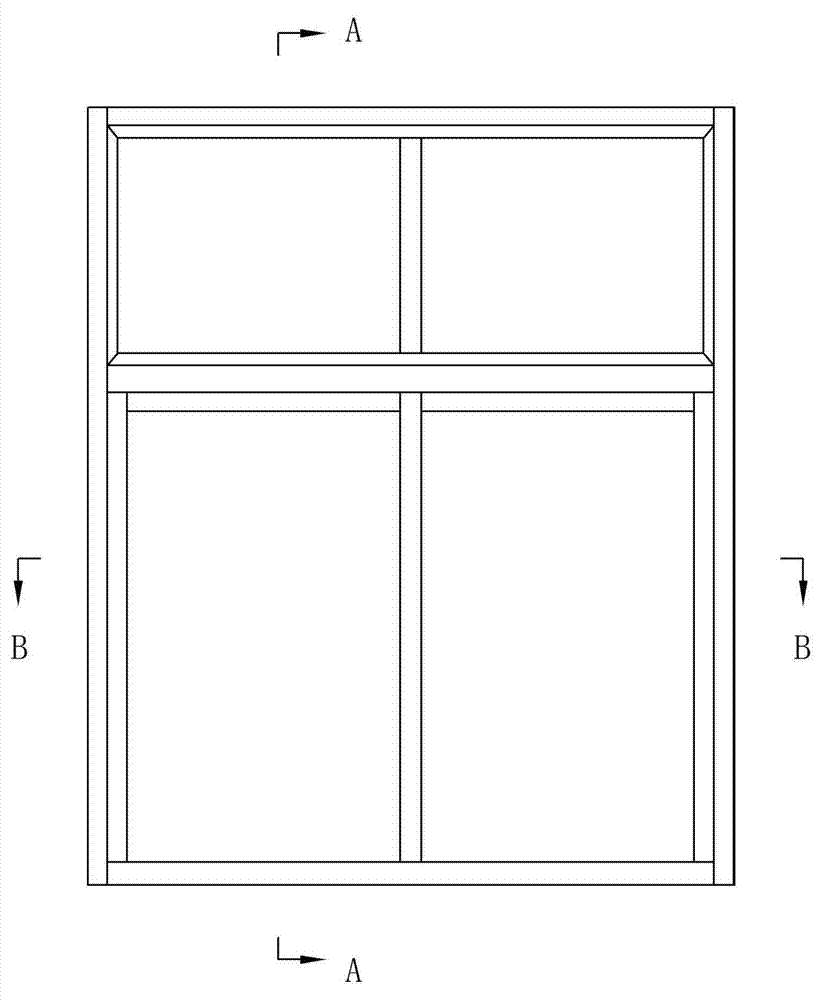

[0040] Embodiment two: see figure 2 , Embodiment 2 is basically the same as Embodiment 1. The symbols in the figure have the same representative meaning as Embodiment 1, and the similarities will not be repeated. The difference is that the window frame profile is a broken bridge profile, that is, the hollow column The left and right parts of the main body are connected by heat-insulating strips 9, which are clamped and fixed by the heat-insulating strip clamping structure, which is correspondingly arranged on the top surface of the hollow cylindrical body 1 and the bottom surface 7, the heat-insulating strip clamping structure includes a vertical support plate 12 perpendicular to the top surface 1 and the bottom surface 7, and one side of the vertical support plate 12 is distributed with fixed chucks 10 and dovetail chucks 11. The heat-insulating strips are rubber strips.

Embodiment 3

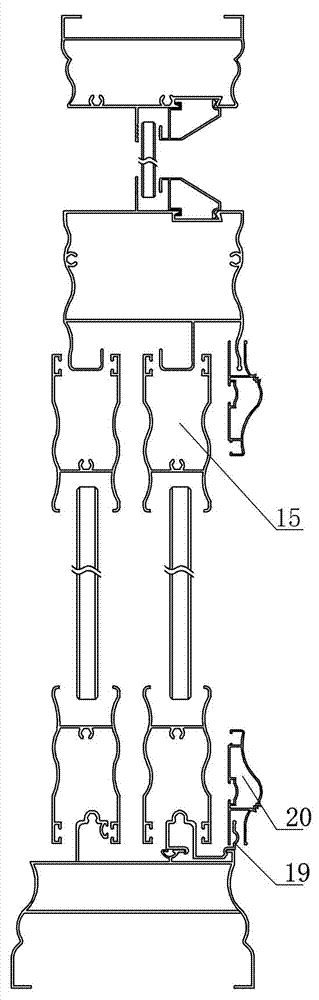

[0041] Embodiment three: see image 3 , Embodiment 3 is basically the same as Embodiment 1. The symbols in the figure have the same meaning as Embodiment 1. The same points will not be repeated. The difference is that the window frame profile is a broken bridge profile, that is, the hollow column The left and right parts of the body are connected by a glue injection connector 13, which is fixed by a glue injection structure arranged between the top surface 1 and the bottom surface 7 of the hollow body. The glue injection structure includes a glue injection cavity and a It consists of a glue injection port 14 arranged on the bottom surface.

[0042] During production, glue is injected into the glue injection cavity through the glue injection port 14, and after the glue is solidified, the top surface 1 is cut off to form a profile as shown in 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com