Modular flow adjustment device

A modular, high-flow technology, applied in wellbore/well valve devices, production fluids, wellbore/well components, etc., can solve problems such as ineffective use of heat energy, imprecise oil well management, and prolonged self-spraying time, etc., to achieve The machining accuracy is easy to guarantee, the performance is reliable, and the effect of extending the self-spraying cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

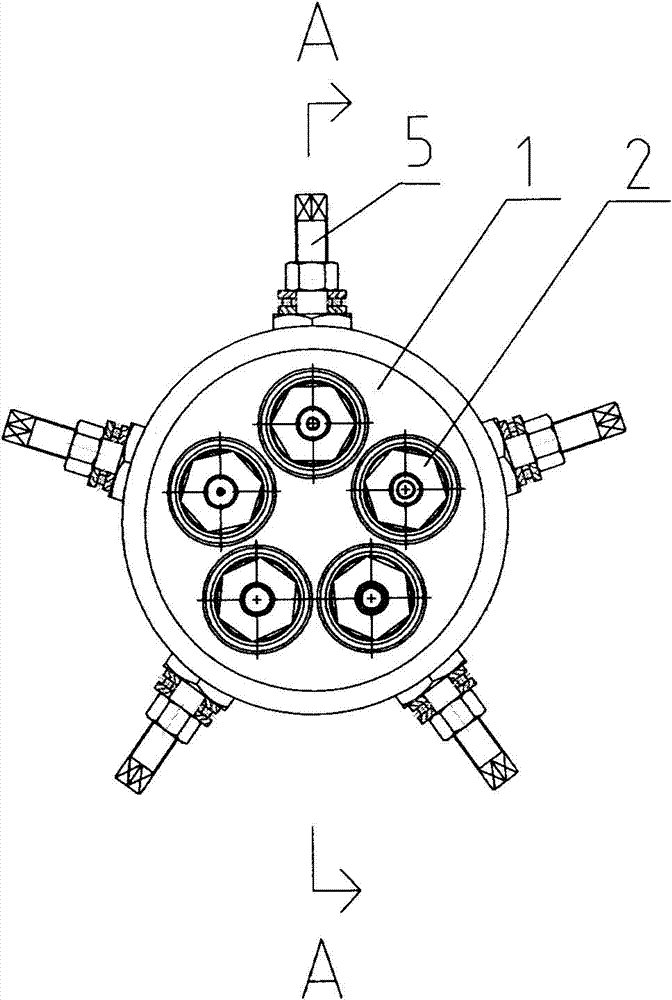

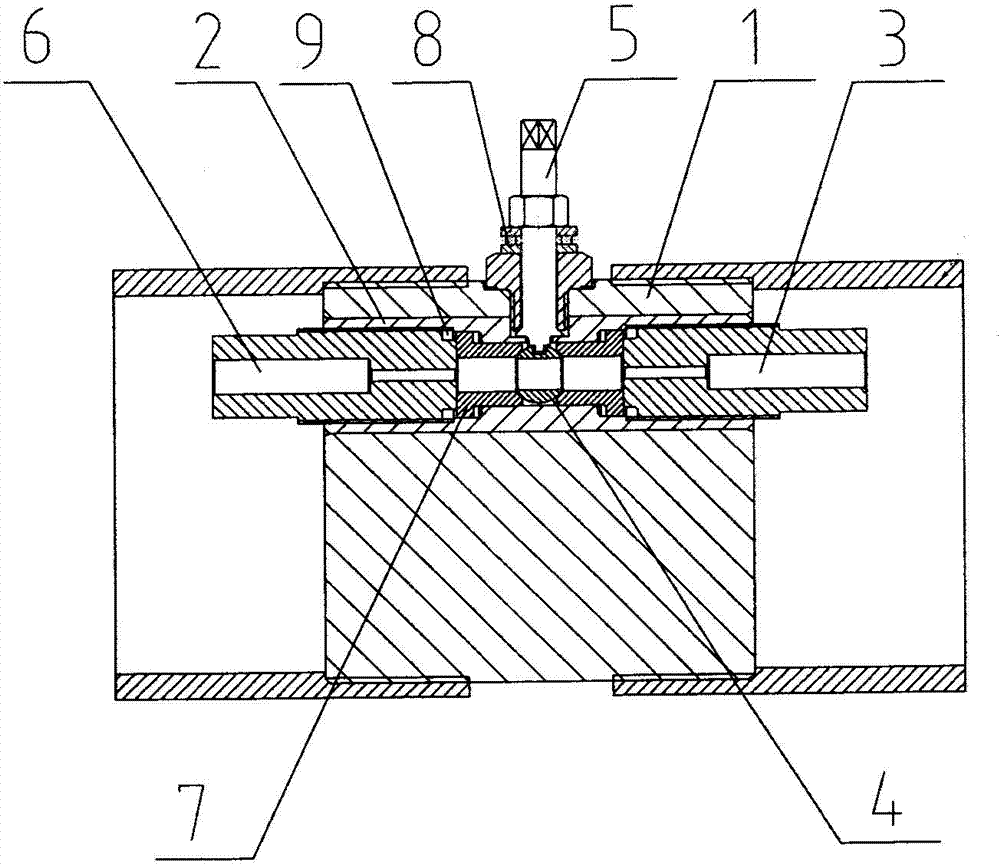

[0016] A modularized flow adjustment device, such as figure 1 , figure 2 As shown, on the circumferential surface of the end face of the cylindrical module base 1 are uniformly arranged through holes axially penetrating the end faces at both ends, and modules with different diameters of inlet and outlet channels 3 and 6 at both ends are fixed in the through holes. 2. A ball valve 4 is arranged between the inlet and outlet channels 3 and 6 at both ends of the module body 2. The rotating shaft 5 of the ball valve 4 extends out of the cylindrical surface of the module base 1, and the through holes are evenly distributed on the end surface of the module base 1. The installed module body 2 has a ball valve rotating shaft 5 radially extending from the cylindrical surface of the module base 1, and connecting threads are respectively provided on the outer cylindrical surfaces of the two ends of the module base 1. Different apertures of inlet and outlet channels 3 and 6 are 1-40mm. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com