Current limiting device with hole diameter adjustable

A current-limiting device and adjustable technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of ineffective use of heat energy, imprecise management of oil wells, and prolonging self-spraying time, etc., to achieve the purpose of prolonging oil well Self-spray cycle, long service life, and the effect of extending the self-spray cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

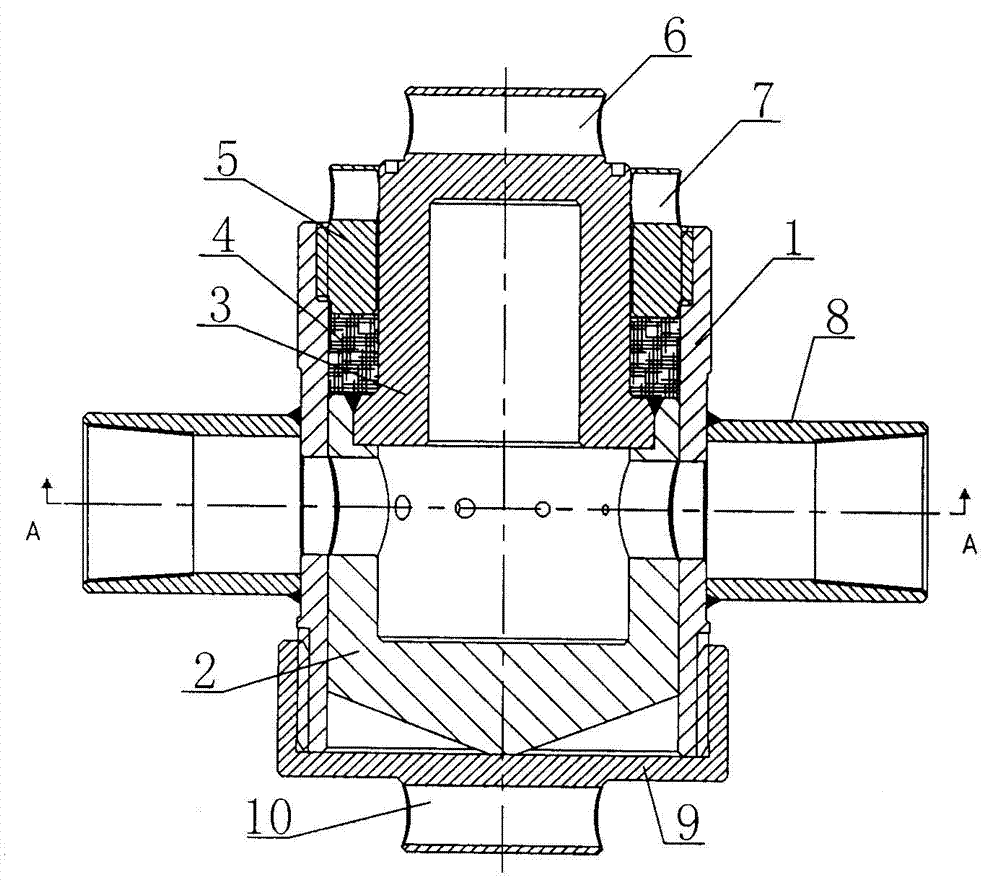

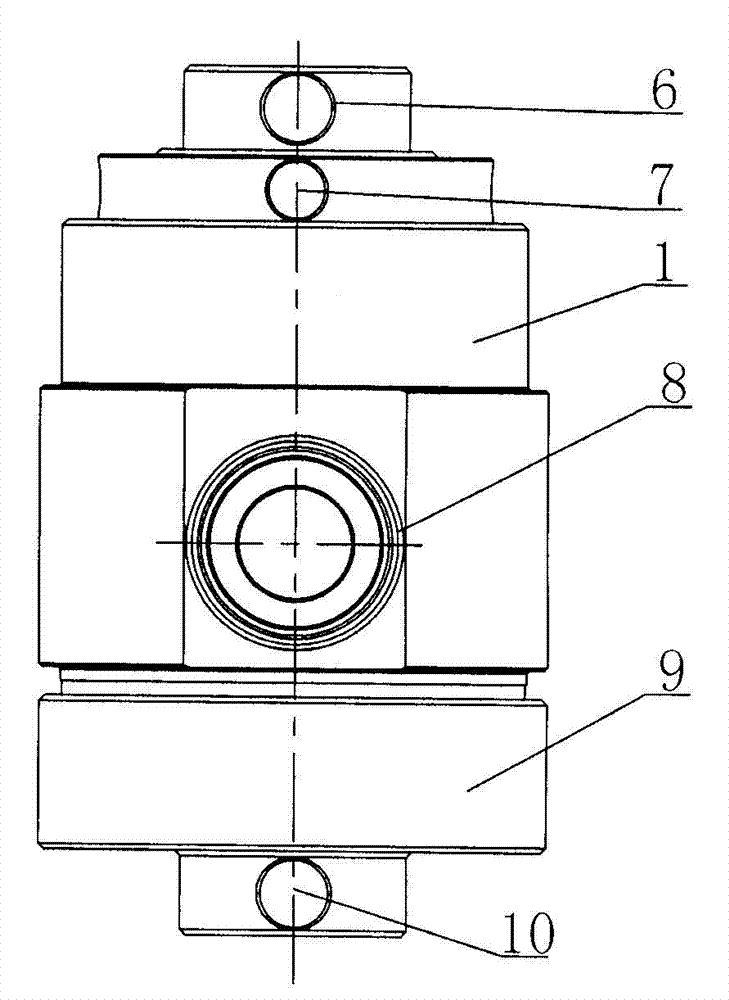

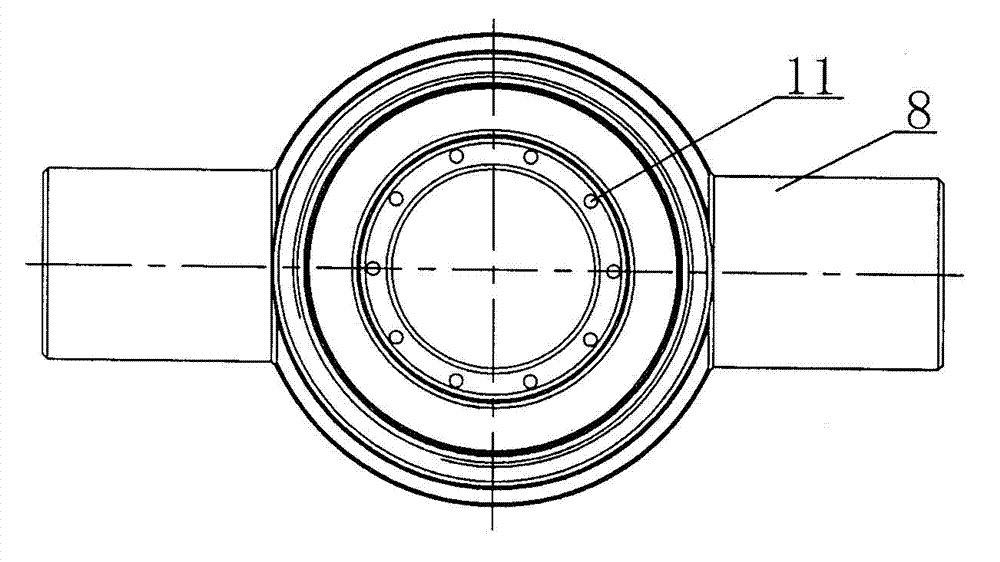

[0019] A flow-restricting device with adjustable pore size, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the rotatable mandrel is fitly installed in the cylindrical mandrel seat 1, and two symmetrical through holes are arranged on the wall of the mandrel seat 1. The outer connecting pipe 8 of the internal thread, the cap 9 is installed through the thread on one end of the mandrel seat 1; the stepped rotatable mandrel is composed of the mandrel 2 and the reduced-diameter connecting shaft 3, and has a cylindrical closed cavity core The shaft 2 is in dynamic fit with the inner hole of the mandrel seat 1. On the mandrel 2, through holes arranged symmetrically from small to large are evenly arranged in the radial direction. Among them, the two symmetrical through holes with the largest diameters on the mandrel 2 The diameters of the two symmetrical through holes on the mandrel base 1 are equal, and the coaxial lines are matched, and the inner hole of the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com