Ram air fan inlet housing

A technology for ram air fans and casings, used in air handling equipment, NACA-type air inlets, air inlets for turbine/propulsion units, etc., to solve the problem of insufficient air flow through heat exchangers, low ram air pressure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

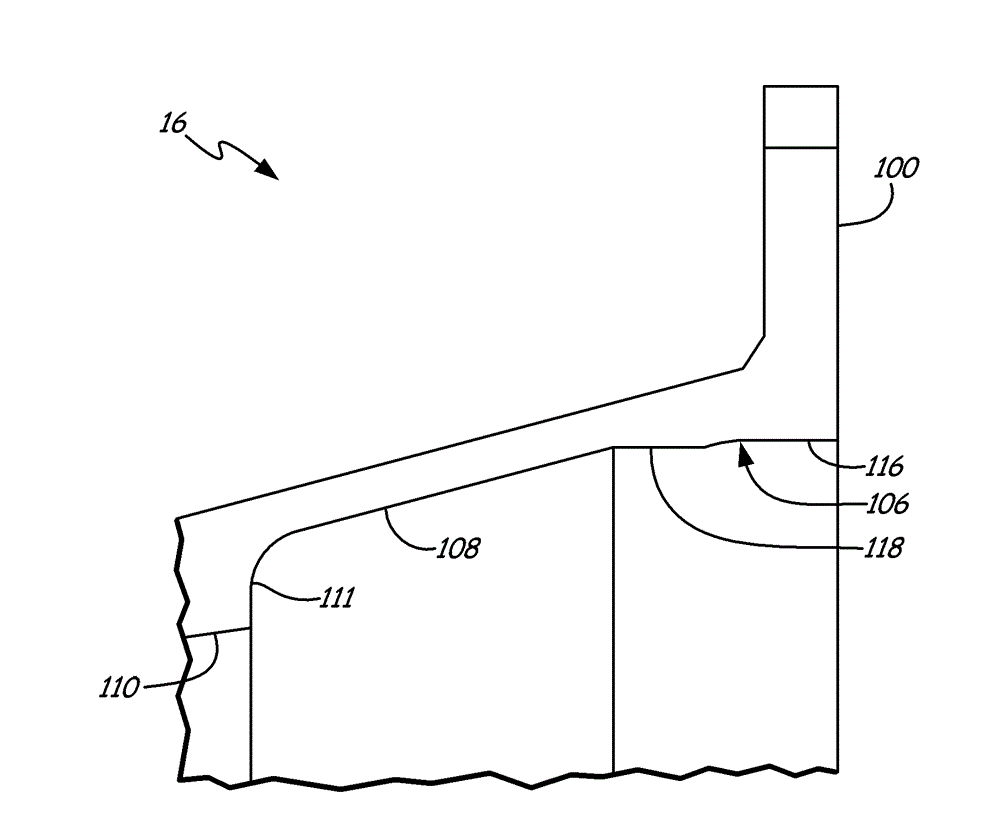

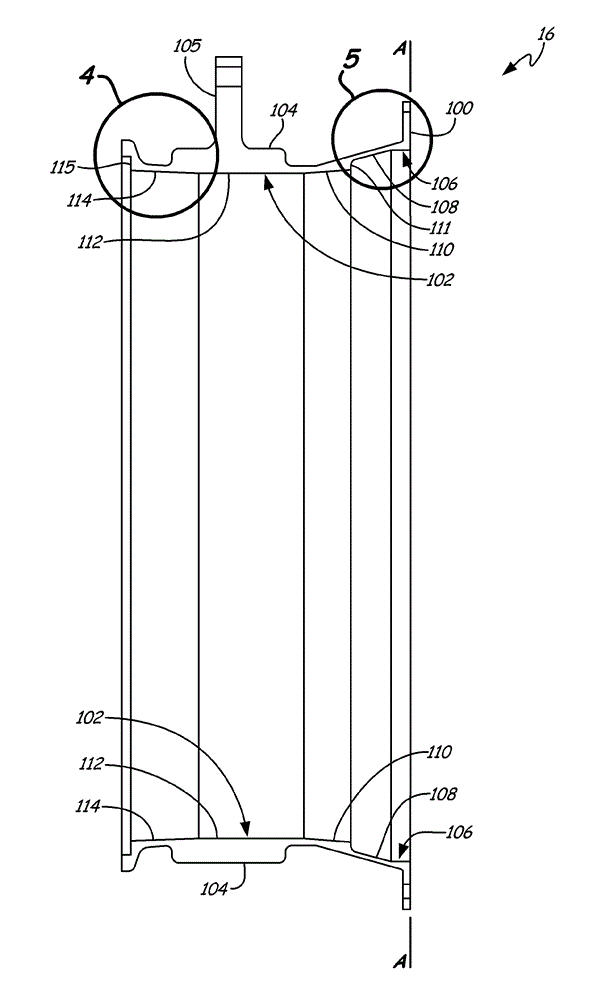

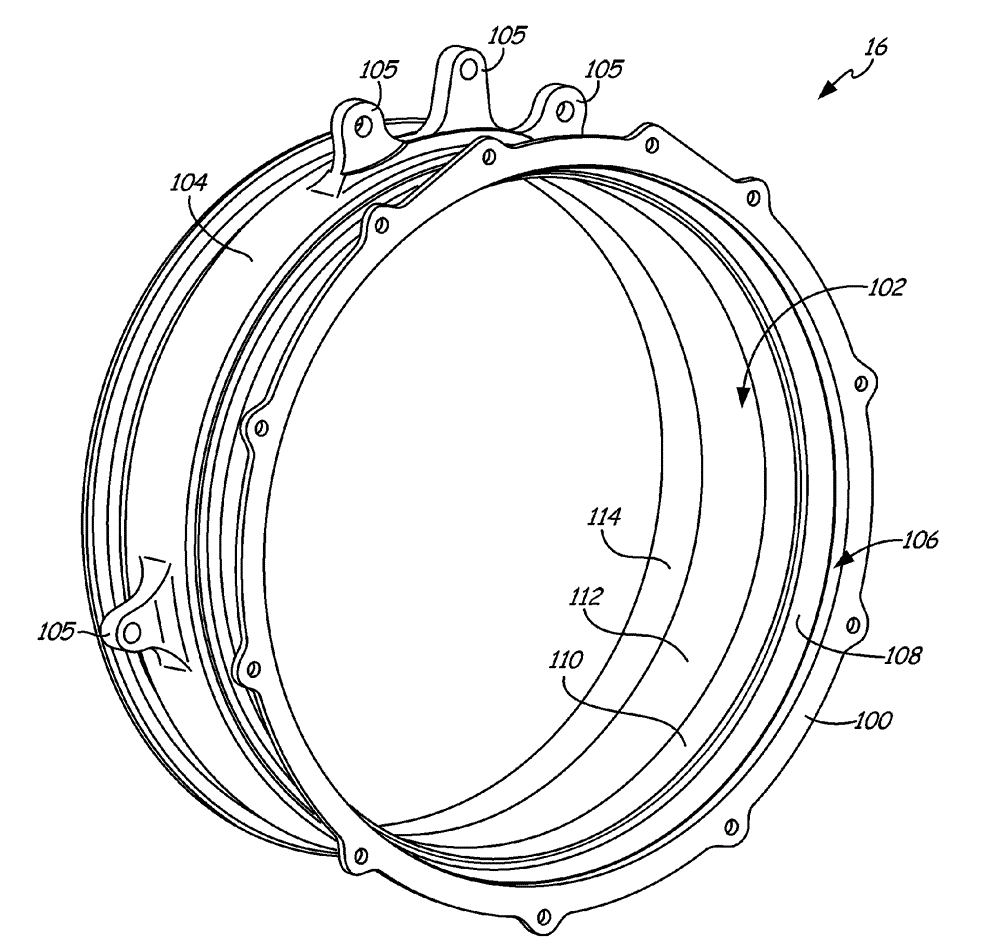

[0011] Conventional ram air fan assemblies in environmental control systems (ECS) employ a fan housing that includes a front or inlet section that surrounds the fan rotor. In this most basic form, such an inlet section has a cylindrical profile with a diameter greater than that of the fan rotor. The closer the fan rotor diameter is to the diameter of the inlet section, the higher the efficiency (air flow rate for a given fan speed) of the ram air fan. However, if the tolerances are too tight, the fan rotor may rub against the inlet section, resulting in damage to the inlet section and a reduction in fan efficiency. Once damaged by fan friction or normal wear, replacement of the inlet section requires replacement of the entire fan housing. This is a laborious and expensive process requiring removal of the ram air fan assembly from the ECS and almost complete disassembly of the entire ram air fan assembly. Finally, although uncommon, mechanical failure or rotor burst of a fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com