Cable watertight stuffing box and using method thereof

A technology for stuffing boxes and cables, applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc., can solve problems such as damage to sensor joints, affect the normal operation of equipment, etc., and achieve the effect of improving watertight characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

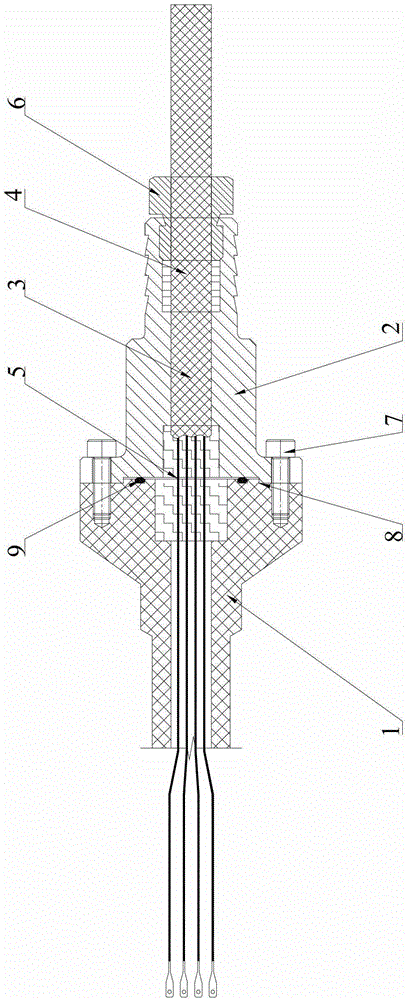

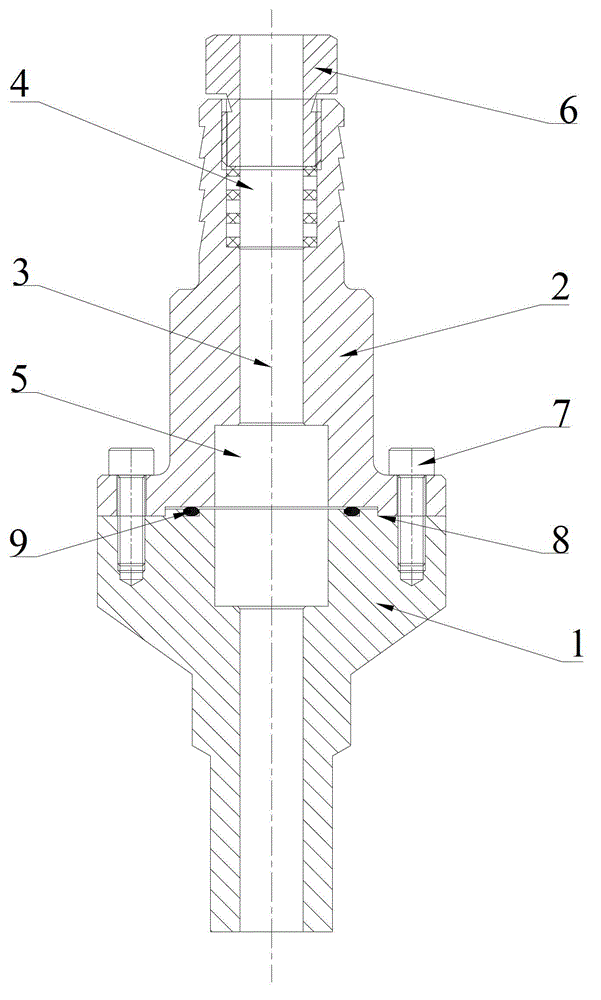

[0024] refer to figure 1 , figure 2 , the present invention provides a cable watertight stuffing box, including a box seat 1 and a box body 2 fixedly connected to the box seat 1, a cable hole 3 penetrating through the box seat 1 and the box body 2, and a cable hole 3 inside the cable hole 3 There are several packing cavities, each of which is provided with a sealing material.

[0025] In the cable watertight stuffing box, several stuffing cavities are arranged in the cable hole 3, and sealing materials are provided in each stuffing cavity, so as to complete the multi-layer sealing protection of the cable in the cable hole, and effectively improve the watertight characteristics of the cable watertight stuffing box.

[0026] As a preferred embodiment of the present invention, the packing chamber includes a first packing chamber 4 located inside the outer port of the box body 2 and a second stuffing chamber 5 located between the box body 2 and the box seat 1 .

[0027] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com