Waterproof method for entrance of shield tunnel

A technology for shield tunneling and tunnel entry, which is applied to tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of limited sampling points, difficult homogeneity, and large soil reinforcement range, and achieve good water tightness and improve safety. coefficient, the effect of avoiding mud and water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

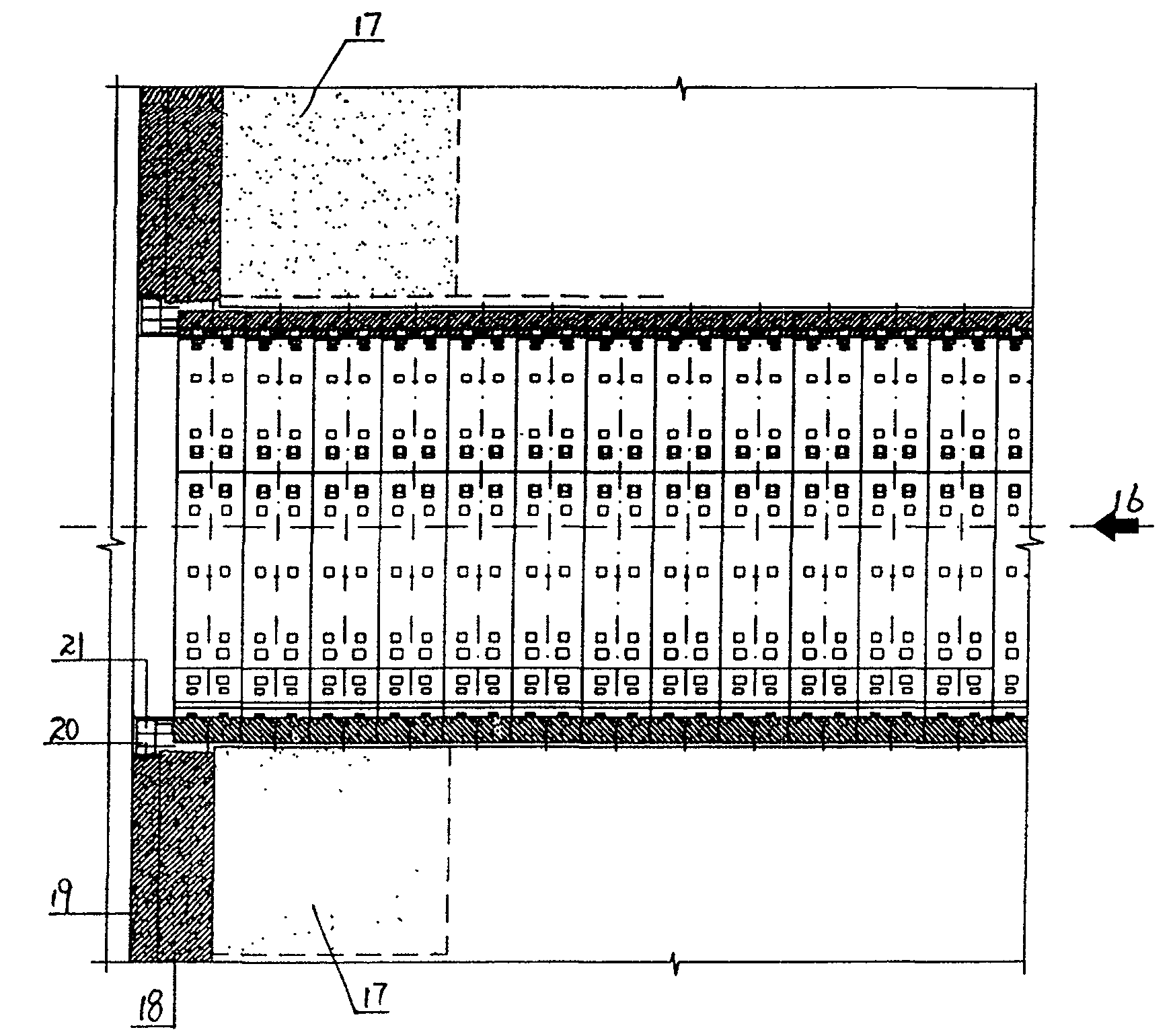

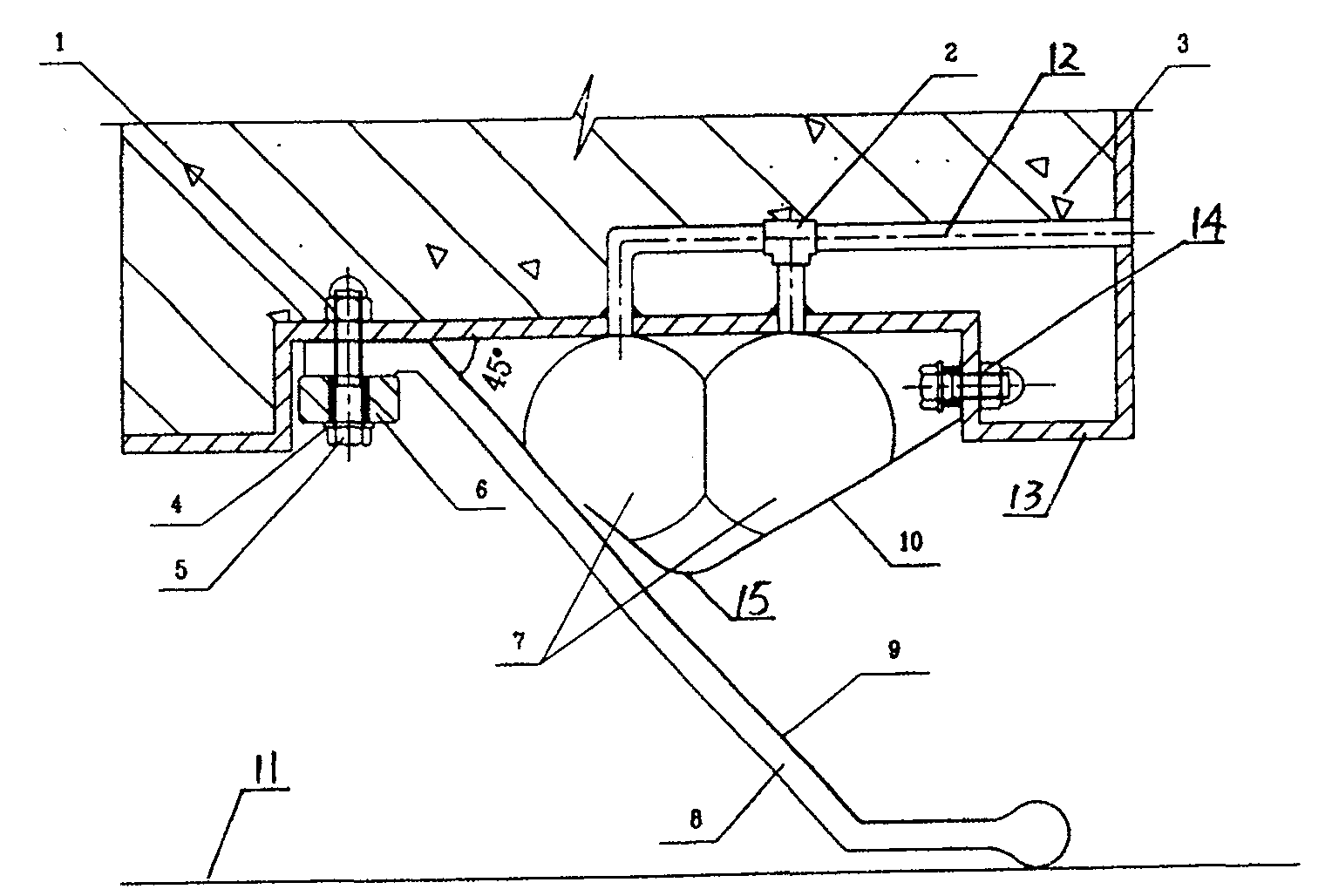

[0016] like Figure 1-2 As shown, the labels 1-21 respectively represent: cap nut 1, tee joint 2, well ring 3, washer 4, bolt 5, pressure block 6, air bag 7, cord rubber plate 8, spring steel plate 9, arc-shaped spring steel plate 10 , the outer wall of the lining segment 11, the air-filled pipe 12, the well ring steel plate 13, the cap nut 14, the arc-shaped end 15 of the arc-shaped spring steel plate 10, the shield driving direction 16, the reinforced soil 17, and the enclosure structure 18. Lining 19, embedded steel ring 20, annular reinforced concrete protection ring 21.

[0017] The tunnel entry waterproofing method of the shield tunnel involved in this embodiment includes the well ring 3, the outer wall of the lining segment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com