Method of rapidly replacing battery boxes

A battery box, fast technology, applied to battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of not being able to achieve fast replacement, waste of manpower, and long time consumption, so as to improve use efficiency, reduce time, and facilitate tracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

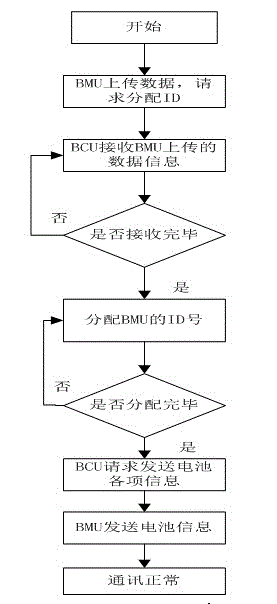

Image

Examples

Embodiment Construction

[0023] In order to facilitate those skilled in the art to understand the technical content of the present invention, the present invention will be further described in detail below in conjunction with the embodiments.

[0024] The method for quickly replacing the battery box disclosed by the present invention, in the specific implementation, the slave control unit of the battery management system implants battery information into it through the host computer during the production process, including the manufacturer, production date, product model, production batch Inferior, and code a barcode for each slave control unit, and establish a one-to-one correspondence between the barcode and the implanted battery information, which is convenient for future tracking. After the slave control unit is installed in the battery box, this unique barcode label is also pasted outside the battery box, so that the internal slave control unit can be identified from the outside of the battery box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com