Vibrating diaphragm used for enhancing middle-frequency band outputs and preparation method thereof

A frequency band and thin film technology, which is applied in the field of diaphragm and its preparation to enhance the output of the mid-frequency band, can solve the problems of high resonance and cold sound of the moving iron unit, so as to reduce high-frequency loss, ease the reduction of mechanical strength, The effect of improving the coldness of the sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

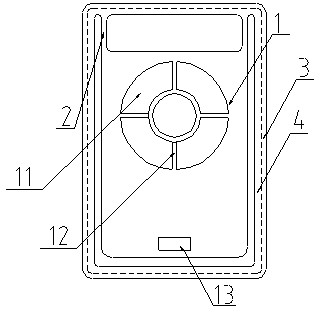

[0024] see figure 1 , as shown in the illustration, a diaphragm that enhances the output of the mid-frequency band includes a diaphragm main body 1, two connecting parts 2, a diaphragm support 3 and a prestressed film 4, and the prestressed film 4 is fixed and tight. Can be sealed on the diaphragm support 3; one end of the diaphragm main body 1 is connected to the diaphragm support 3 through the connecting part 2, the diaphragm main body 1 includes a front and a back; the front or back is in contact with the prestressed film 4; the diaphragm The main body 1 is provided with a cavity 11; the cavity 11 communicates with the above-mentioned front and back; the cavity 11 is connected with a partition 12.

[0025] The cross-sectional area of the cavity 11 on the front and back is 25% of the area of the front and back respectively, and the cross-sectional area of the partition 12 on the front and back is 40% of the cross-sectional area of the cavity 11 respectively.

[002...

Embodiment 2

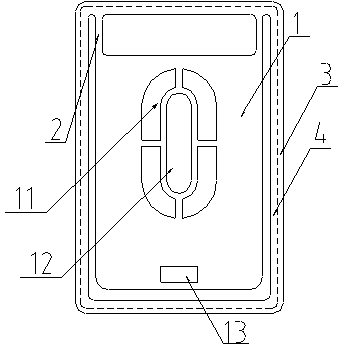

[0033] see figure 2 , as shown in the legend therein, the rest is the same as that of Embodiment 1, the difference is that the cross section of the cavity 11 is elliptical, and the cross section of the partition 12 is elliptical.

[0034] The diaphragm main body 1 , the connecting portion 2 and the diaphragm support 3 are made of copper or aluminum-magnesium alloy.

Embodiment 3

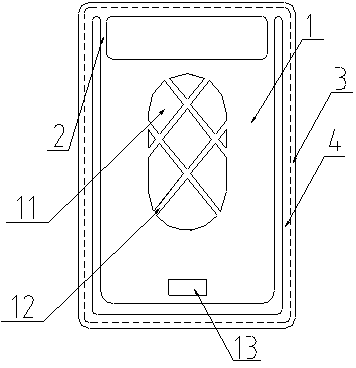

[0036] see image 3 , as shown in the legend therein, the rest is the same as that of Embodiment 1, except that the cross section of the cavity 11 is elliptical, and the cross section of the partition 12 is grid-shaped.

[0037] The diaphragm main body 1 , the connecting portion 2 and the diaphragm holder 3 are made of iron-nickel alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com