Large flexible printed circuit (FPC) and typesetting method of manufacturing FPC

A technology of layout and dislocation distribution, used in the structural connection of printed circuits, printed circuit components, and electrical components to assemble printed circuits, etc., can solve problems such as FPC damage, reduce waste, reduce damage, and reduce The effect of damage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below:

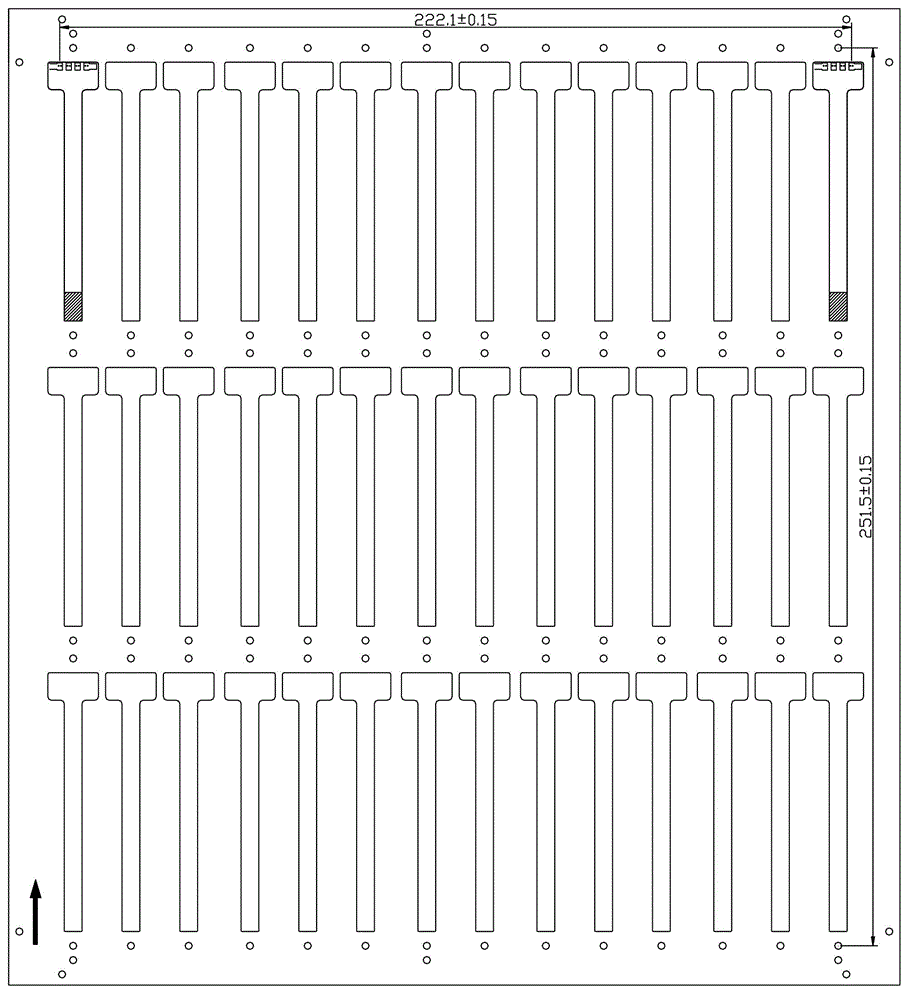

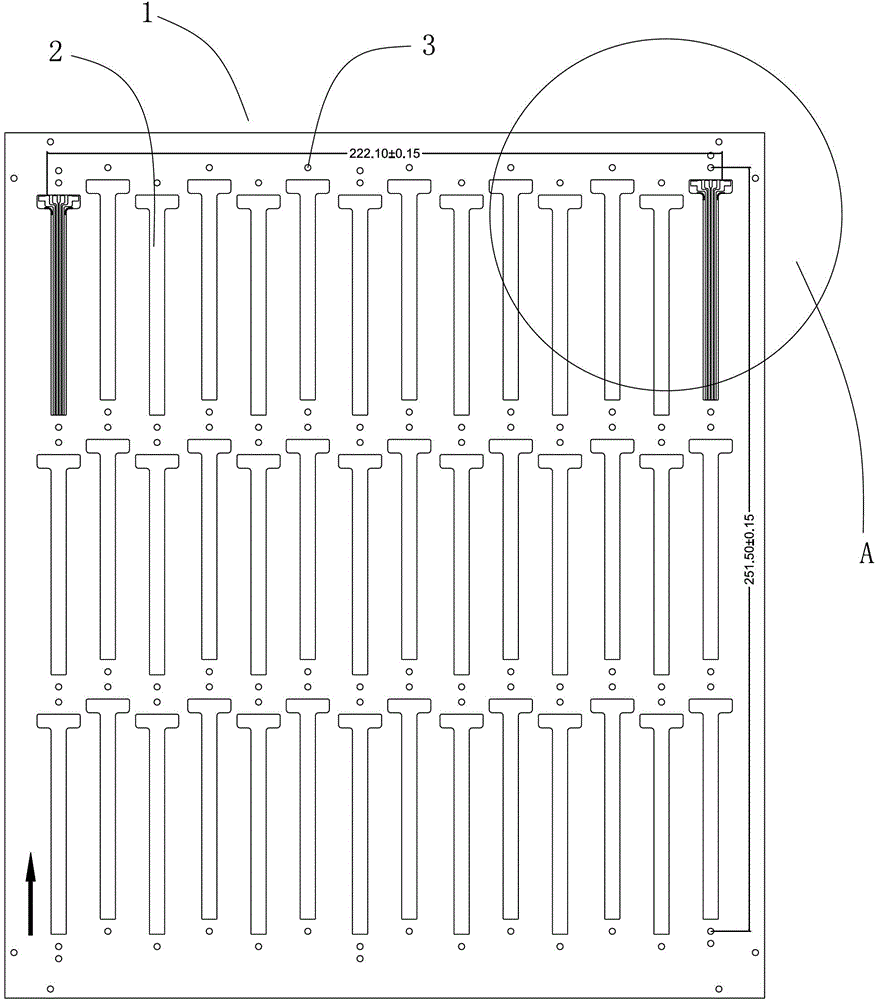

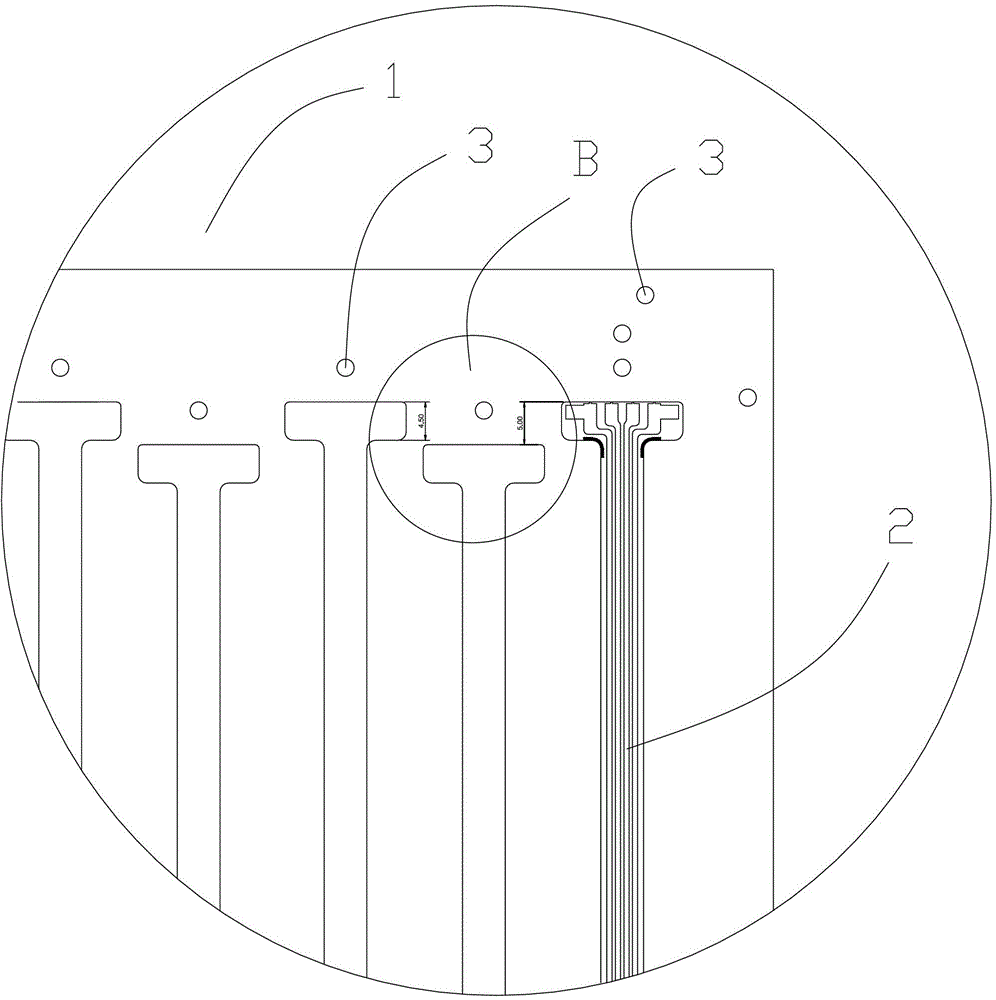

[0028] like figure 2 As shown, a large FPC1 includes several FPC units 2 arranged thereon; the several FPC units 2 are misplaced on the layout of the large FPC1.

[0029] After staggering the layout of FPC unit 2, the generated stress is dispersed, the stress intensity becomes smaller, and the proportion of fractures is reduced. Both the large-sheet FPC1 production process and the large-sheet FPC1 blanking process increase the yield rate. The FPC with a length of 72.5 mm and a model number of GITO.6370 as described in the embodiment is taken as an example. The yield rate has increased from about 65% to over 80%, mainly because the defective rate of damage during the operation has been controlled.

[0030] The FPC units 2 are arranged in the same direction. Compared with the random typesetting method, this typesetting method can arrange as many FPC units 2 as possible on the layout of the same area....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com