A kind of buckwheat tea and preparation method thereof

A technology of buckwheat tea and buckwheat is applied in the field of food processing to achieve the effects of fresh and mellow inner quality, avoiding waste, and having a dark green and smooth color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

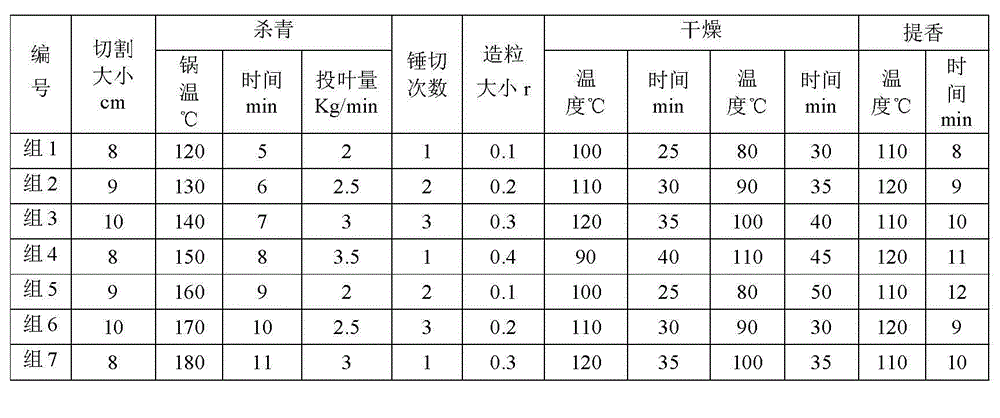

[0053] 1. Raw material pretreatment: select the whole plant of artificially cultivated buckwheat, mainly including buckwheat leaves, stems, flowers, and buckwheat grains, and the harvesting period is the buckwheat filling period. Clean the whole harvested buckwheat plant, spread it out to dry the surface water, and cut the whole buckwheat plant into short sections of 10cm when the leaves are soft.

[0054] 2. Finishing: The whole buckwheat plant cut into short sections is fried in a continuous pot, the temperature of the pot is 140°C, the time is 7 minutes, and the amount of leaves thrown is 3kg / min. After finishing, spread the green leaves to dry for later use.

[0055] 3. Mixing: a compound formula is adopted, and its formula (mass ratio) is: buckwheat husk: buckwheat seed: green tea powder: whole buckwheat plant (after greening) is 5:10:10:75, mix well and set aside.

[0056] 4. Hammer cutting: the mixed raw materials are hammered with a hammer cutter, the number of times ...

Embodiment 2

[0063] 1. Raw material pretreatment: select the whole plant of artificially cultivated buckwheat, mainly including buckwheat leaves, stems, flowers, and buckwheat grains, and the harvesting period is the buckwheat filling period. Clean the whole harvested buckwheat plant, spread it out to dry the surface water, and cut the whole buckwheat plant into 9cm short sections for later use when the leaves are soft.

[0064] 2. Finishing: The whole buckwheat plant cut into short sections is fried in a continuous pot, the temperature of the pot is 120°C, the time is 9 minutes, and the amount of leaves thrown is 2kg / min. After finishing, spread the green leaves to dry for later use.

[0065] 3. Mixing: a compound formula is adopted, and its formula (mass ratio) is: buckwheat husk: buckwheat seed: green tea powder: whole buckwheat plant (after greening) is 10:5:10:75, mix well and set aside.

[0066] 4. Hammer cutting: The mixed raw materials are hammered with a hammer cutter, the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com