Dust removing system and auxiliary dust removing device

The technology of a dust removal system and a dust removal device is applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., which can solve the problems of large amount of dust, affecting dust removal efficiency, increasing labor costs, etc., to alleviate the impact of service life, Guaranteed emission concentration and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

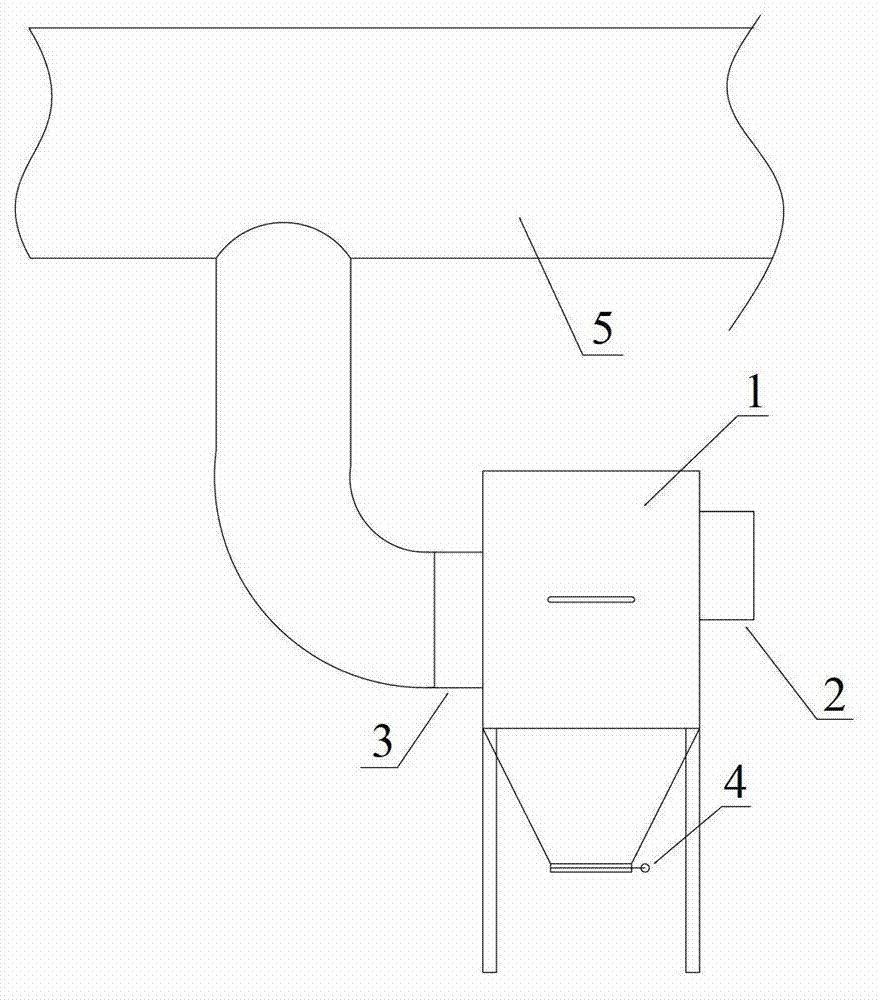

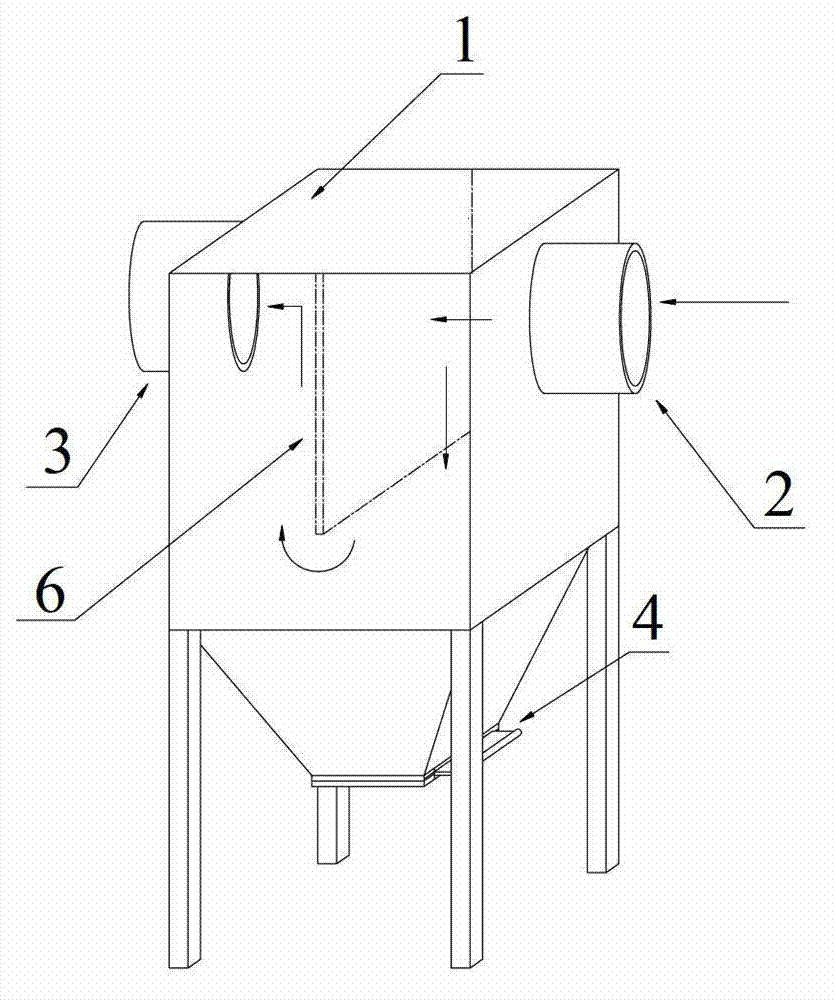

[0029] The dust removal system of this example includes a dust remover and a dust removal pipeline 5, and an auxiliary dust removal device. The dust remover is connected to the end of the dust removal pipeline 5 to provide power for the dust removal system. The connection mode between the dust remover and the dust removal pipeline is the same as that of a conventional dust removal system; The dust removal device is connected to the dust suction hole end of the dust removal pipeline 5, and the connection mode between the auxiliary dust removal device and the dust removal pipeline is as follows: figure 1 shown. The auxiliary dust removal device in this example, such as figure 2 As shown, it includes a box body 1, a side wall on the box body 1 is provided with a dust suction port 2, and a dust discharge port 3 is provided on the side wall opposite to the side wall where the dust suction port 2 is set; the dust discharge port 3 The caliber of the dust suction port 2 is about 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com