Special differential shell type elastic clamping tooling for helical gear

A technology of elastic clamping and helical gears, which is applied in the direction of clamping, positioning devices, manufacturing tools, etc., can solve problems such as inability to process workpieces, and achieve the effects of good coaxiality, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

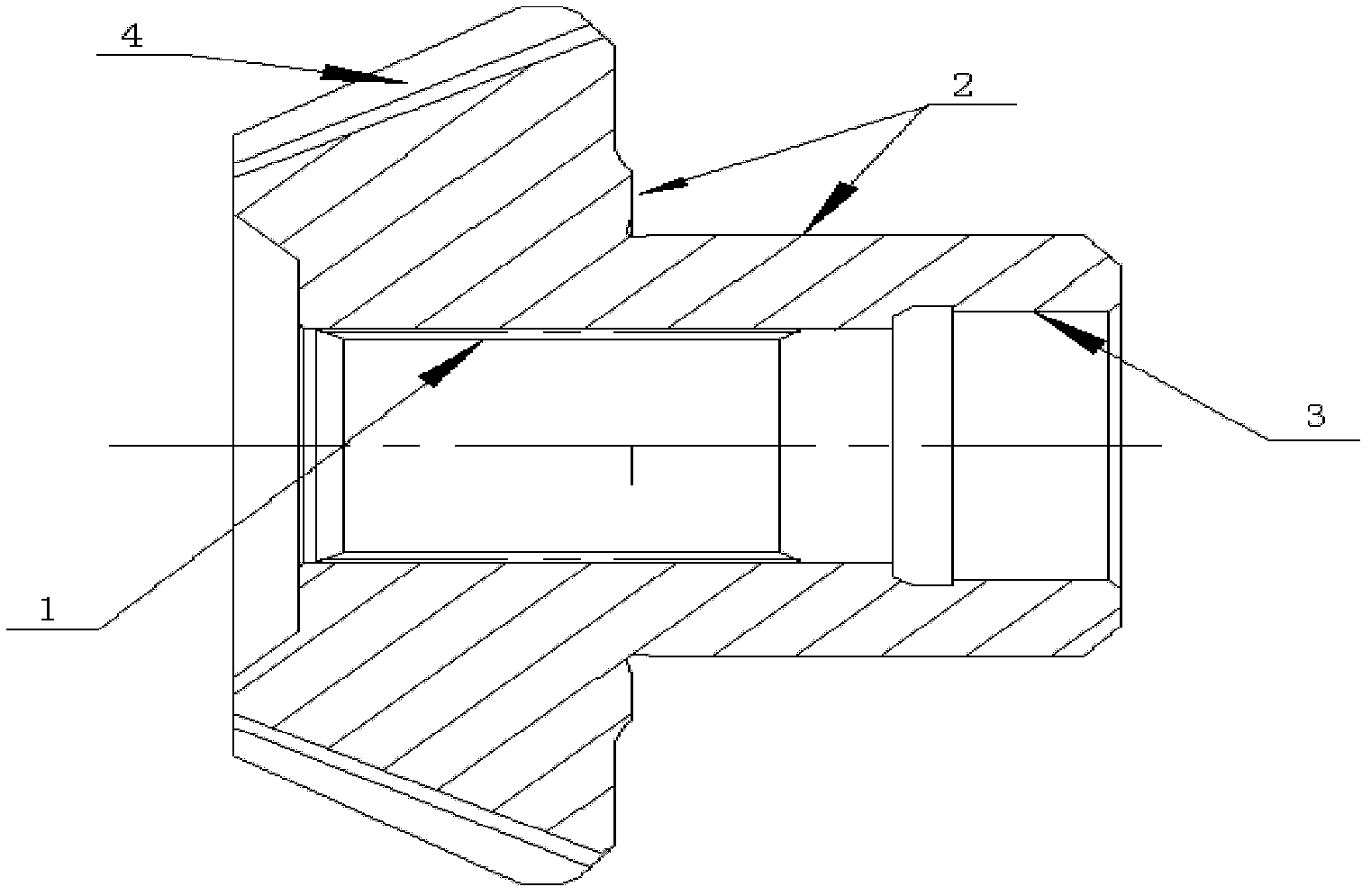

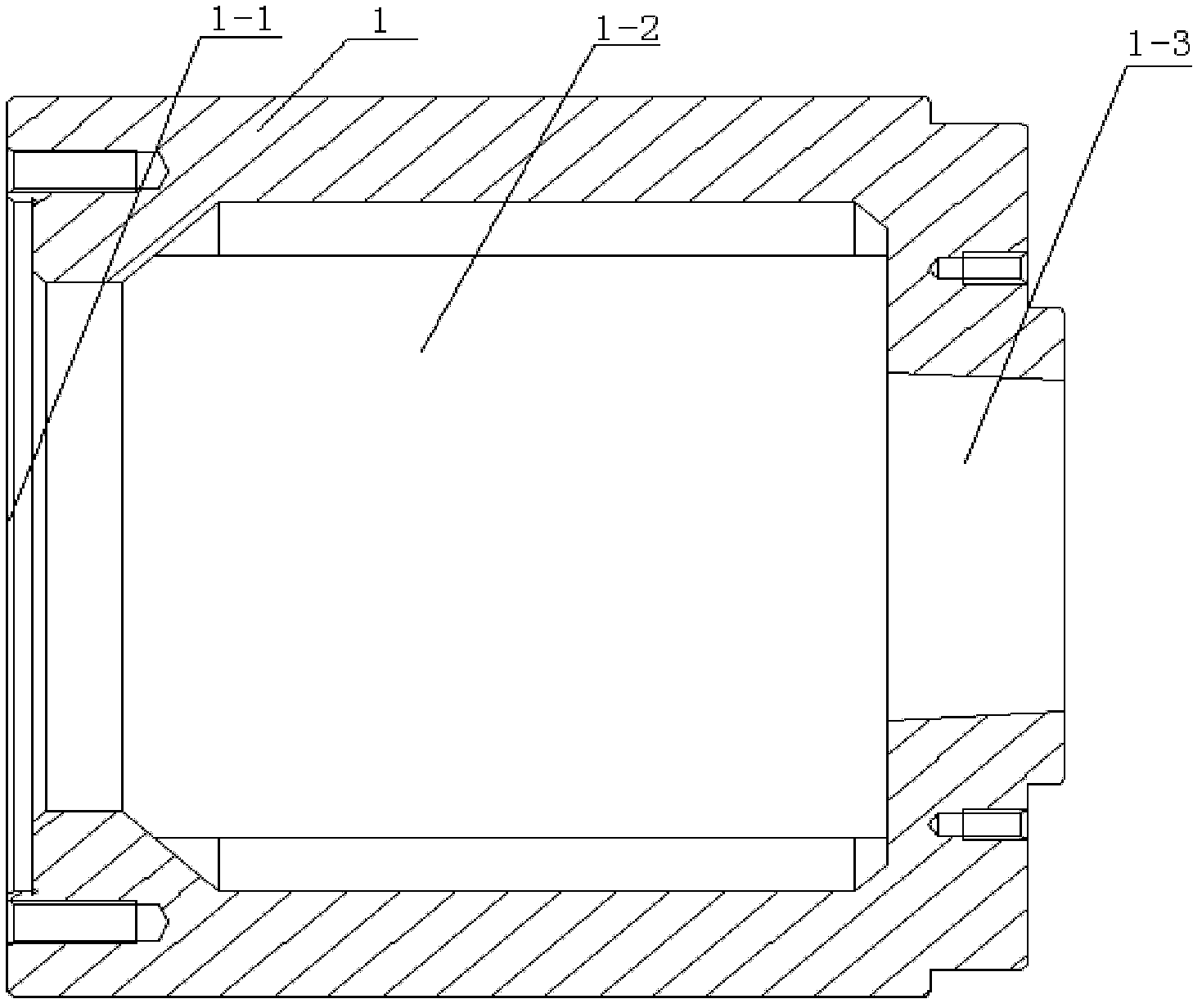

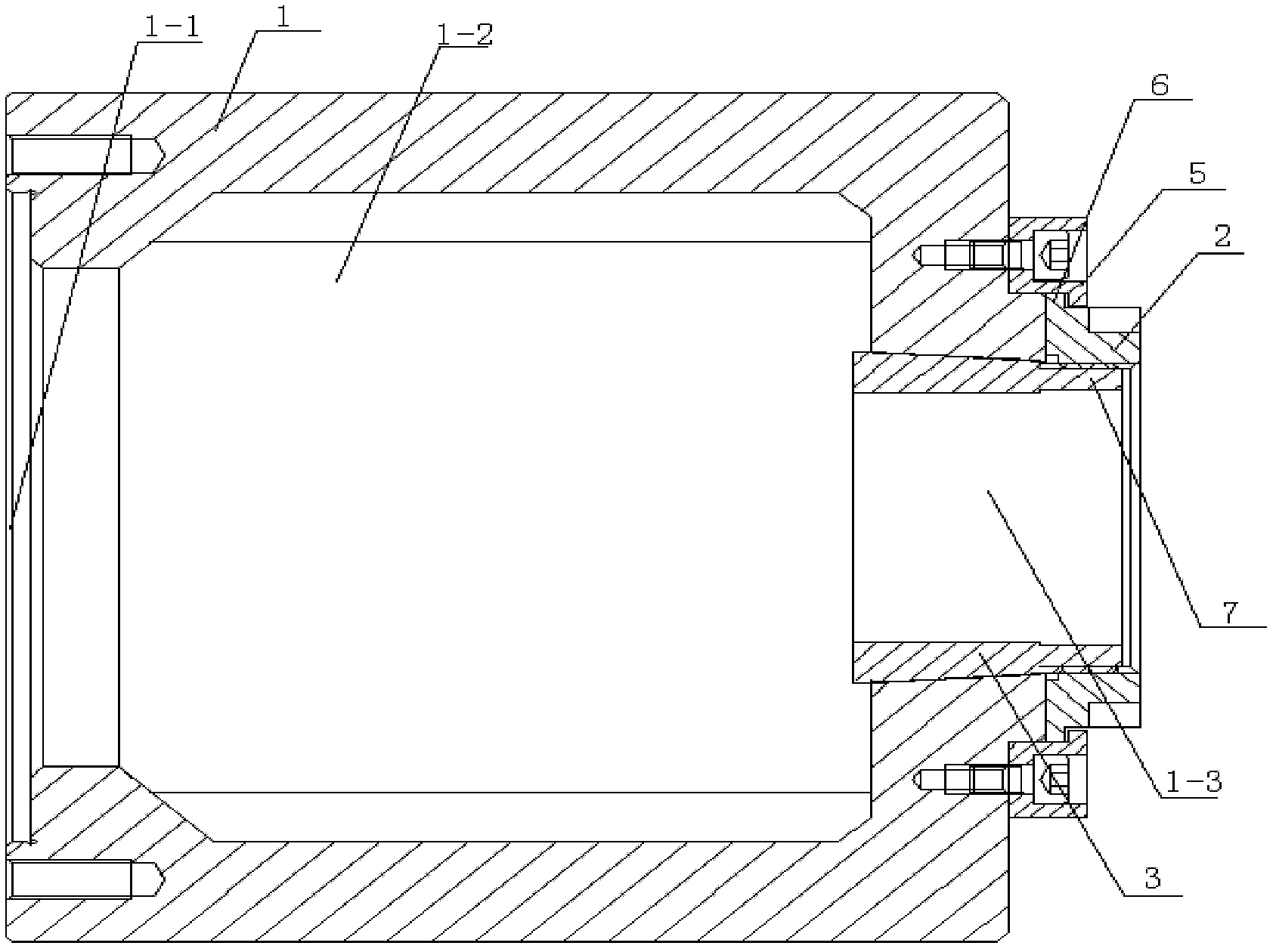

[0013] see figure 2 , image 3 and Figure 4 , the special differential shell type elastic clamping tool for helical gears, comprising a differential shell type main body 1, an elastic cap 2 and an elastic sleeve 3; the differential shell type main body 1 is provided with a connecting hole for directly connecting the grinding machine spindle 1-1 and the loading and unloading hole 1-2 for putting the transfer case gear 4 into the differential housing body 1 and the positioning hole 1-3 for positioning the transfer case gear 4; the elastic sleeve 3 is installed in the positioning In the hole 1-3 and matched with the positioning hole 1-3, the front end of the elastic sleeve 3 extends out of the positioning hole 1-3, and the thickness of the elastic sleeve 3 is from the inside of the differential shell body 1 to the differential shell type along its axial direction The outside of the main body 1 gradually becomes smaller. In this embodiment, the axial section of the sleeve wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com