Cable extrusion test run process

A process and cable technology, which is applied in the field of cable extrusion and commissioning process, can solve the problems of uneven processing technology, cable quality and safety hazards, and a large number of wastes, so as to avoid low mechanical strength and avoid cable material. The effect of scrapping and solving the waste of cable material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0042] The cable extrusion test run process includes the following steps:

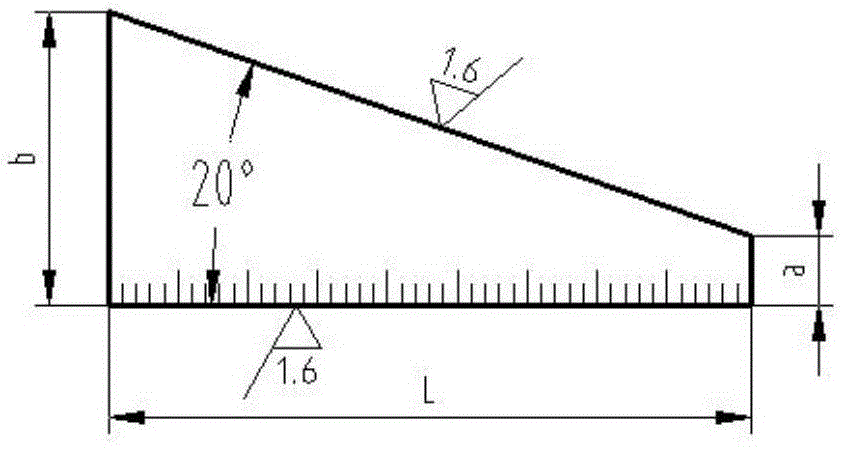

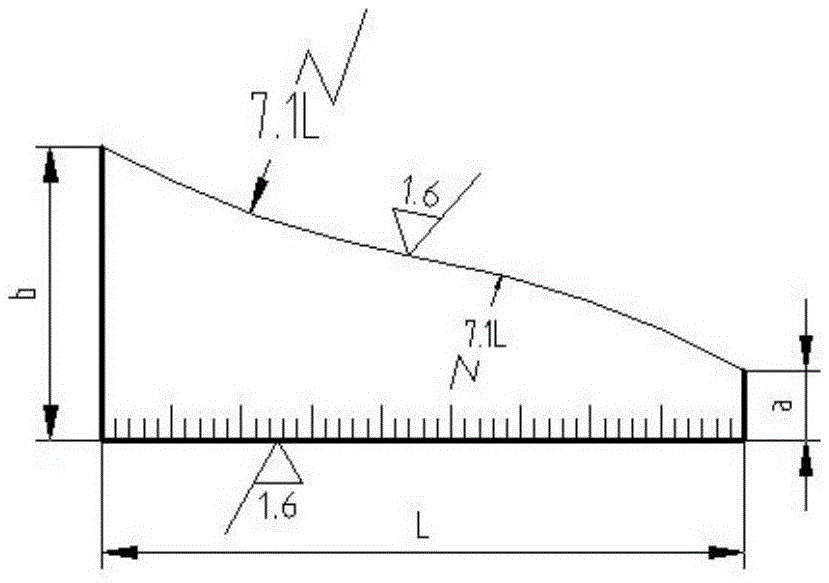

[0043] 1) Select the mold core 2 and the mold sleeve 3 according to the extrusion thickness of the cable. After the above two are installed, insert the wedge-shaped ruler 1 into the gap between the mold core 2 and the mold sleeve 3 to measure, and at the same time check the mold core 2 and the mold sleeve 3. Axis for precise adjustment; such as Figure 6 shown.

[0044] At the outlet end between the mold core 2 and the mold sleeve 3, insert a wedge-shaped ruler 1 into the gap between the mold core 2 and the mold sleeve 3 for measurement, and select at least two symmetrical positions along the central axis of the mold core 2 for measurement;

[0045] When measuring, insert the wedge-shaped ruler 1 into the gap between the mold core 2 and the mold sleeve 3, and make the slope or s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com