Method for mounting and centering rotating shaft supported by bearing bush with parallels

A pad iron and rotating shaft technology, which is applied in the field of installation and alignment of equipment rotating shafts, can solve problems such as low efficiency, and achieve the effect of improving equipment installation efficiency

Inactive Publication Date: 2012-07-04

PANGANG GRP ENG TECH +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to overcome the inefficiency of the existing installation and alignment method of the shaft supported by the bearing pad with shim iron, the technical problem to be solved by the present invention is to provide an installation of the shaft supported by the bearing pad with shim iron with higher installation efficiency. Find the right way

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0032] By adopting the method of the present invention to install the main shaft of a certain large-scale turbine, the saved installation period reaches 60 days.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

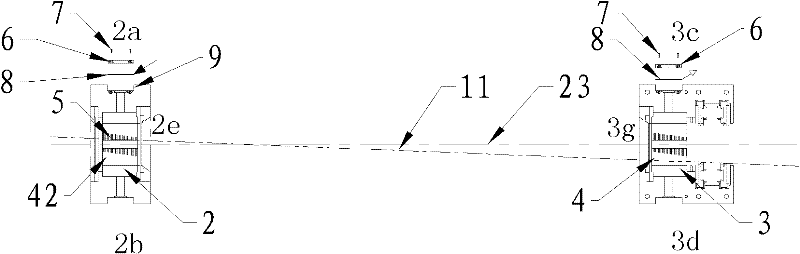

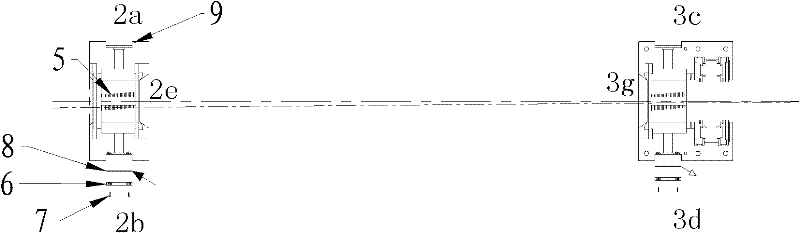

The invention discloses a higher mounting efficiency method for mounting and centering a rotating shaft supported by a bearing bush with parallels. The method comprises the following steps of: uniformly coating a coloring layer on a shaft neck, rotating the rotating shaft, and checking a color strip on the bearing bush caused by friction with the shaft neck; after determining the deflection direction of the centre line of the rotating shaft relative to two bearing centre lines, removing the color strip, and adjusting the thickness of the parallels contacted with a supporting bearing and a thrust bearing according to the deflection direction; and repeating the previous step until the color strip in the step meets the requirement that traces on two left and right sides of the centre line ofthe lower bearing bush are parallel and symmetrical about each other and are continuous in the axial direction of the bearing bush, and checking whether the coaxiality of the centre line of the rotating shaft and the centre line of two bearings meets the mounting requirement. Compared with the traditional turbine axle centering technology, the method saves complicated calculation, and greatly improves the device mounting efficiency. Therefore, the method has more practicality and operability.

Description

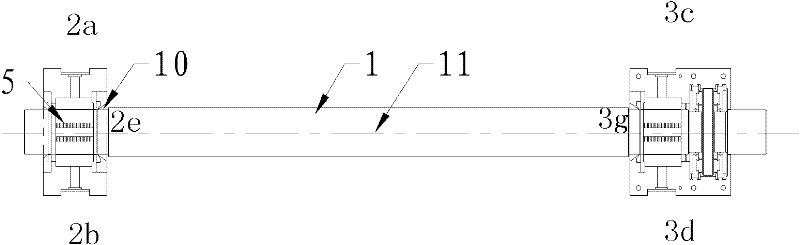

technical field [0001] The invention relates to a method for installing and aligning a rotating shaft of equipment, in particular to a method for installing and aligning a rotating shaft supported by a bearing bush with pad irons. Background technique [0002] At present, large-scale equipment such as blast furnace top gas residual pressure recovery turbine generators, etc., in order to minimize the vibration and noise during equipment operation and prolong the service life of the equipment, all have requirements for the installation of the shaft, especially between the shaft and the bearing. The coaxiality should meet the requirements. A rotating shaft supported by bearing pads with backing irons. The journals of the rotating shaft are respectively supported by support bearings and thrust bearings. There is a bearing pad between each bearing and the rotating shaft. The bearing pad is composed of an upper pad and a lower pad. There is a shim, that is, the upper shim, and th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B5/25G01B5/252G01B5/06

Inventor 朱明龚建华王志伟

Owner PANGANG GRP ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com