A Method for Realizing Segmented Virtual Streamline Construction of Ship Curved Surface

A segmented and streamlined surface technology, applied in the field of manufacturing, can solve problems such as no continuous adjustment research and unsatisfactory application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

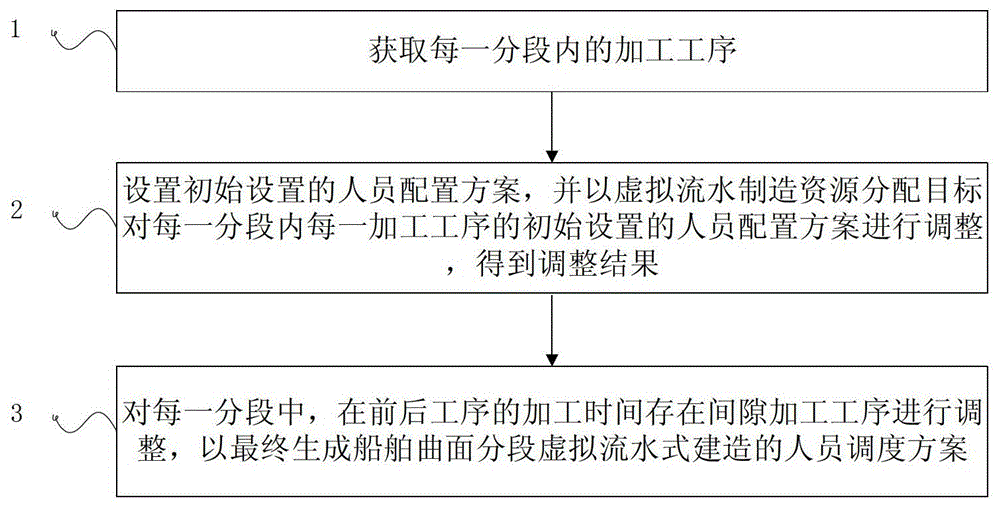

[0043] Embodiments of the present invention provide a method for realizing segmental virtual flow-through construction of ship curved surfaces, including:

[0044] Step 1. Obtain the processing procedures in each segment;

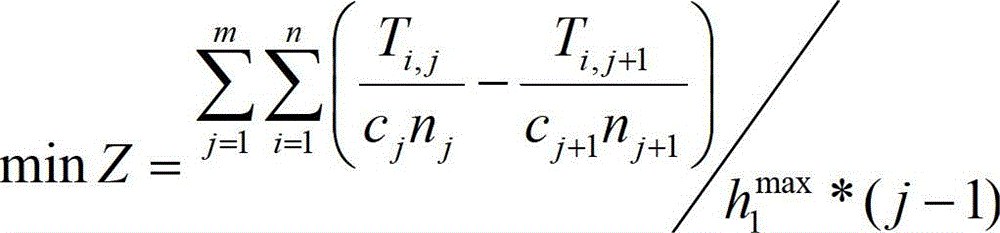

[0045] Step 2. Set the initial staffing plan, and adjust the initial staffing plan for each processing procedure in each segment with the virtual flow manufacturing resource allocation target, and assign processing to each processing procedure according to the adjustment result personnel;

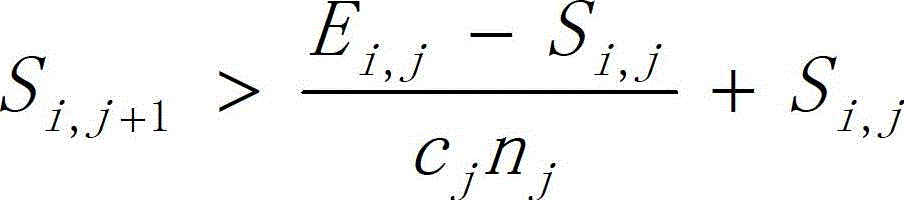

[0046] Step 3. In each section, adjust the processing procedures with gaps in the processing time of the preceding and following procedures, so as to finally generate a personnel scheduling plan for the virtual streamlined construction of the ship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com